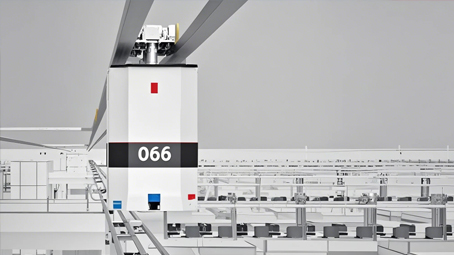

EPS production line

Application background:

In the field of steel manufacturing, the treatment of oxide scale on the surface of hot-rolled coils is a key step in ensuring product quality. Traditional EPS production lines usually rely on imported PLC for automatic control, but this mode has problems such as strong technical dependence, high maintenance costs, and high supply chain risks. Sinsegye optimized the control system for the EPS production line of a certain steel enterprise, replacing the original imported brand PLC with the self-developed SX21 series iComputer, successfully achieving domestic substitution of hardware and operating system.

Customer pain points:

The steel industry is an important pillar of the national economy, and as a basic material, the surface treatment quality of hot-rolled coils directly affects the performance of subsequent processing and end products. The traditional EPS production line relies on imported PLC systems and faces the following challenges:

- High technical barriers: The core technology of imported PLCs is constrained by foreign manufacturers, making it difficult for enterprises to conduct in-depth customized development;

- High maintenance costs: long spare parts procurement cycle, slow technical service response, affecting production continuity;

- Supply chain risk: Changes in the international situation may lead to the interruption of critical equipment supply, posing a threat to production safety;

- Insufficient intelligence: Traditional PLCs are unable to meet the needs of modern industry for real-time data analysis and intelligent decision-making.

Scenario solution framework:

Characteristics of SINSEGYE's solution

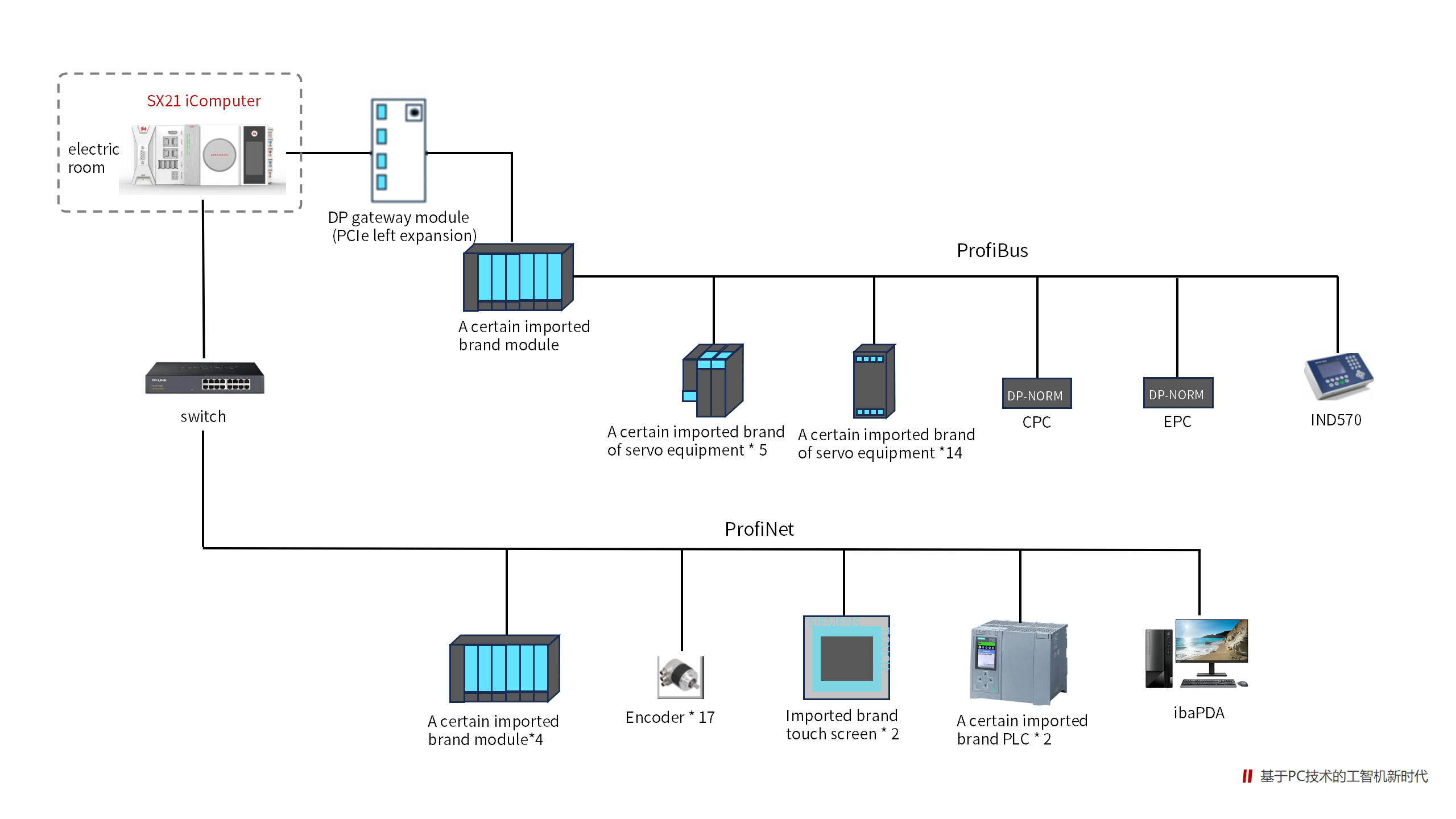

1、Integrated Control and Computation&domestic substitution

Using SX21 series iComputer as the main control core, equipped with Sinegye MetaOS dual domain operating system, to achieve nationwide production of hardware and operating system;

2、Easy to use and open

Integrate numerous protocols such as PLC, Motion, OPC/UA, Modbus, EtherCAT, etc; Support expansion modules such as gigabit Ethernet ports, AI inference cards, serial ports, wireless, remote IO, etc;

3、Edge computing

Support data collection, data storage, etc., can be pre installed with intelligent device monitoring and diagnostic system Instaguard, production decision assistance system MesApps, etc