EPS production line

In the field of steel manufacturing, the treatment of oxide scale on the surface of hot-rolled coils is a key step in ensuring product quality. Traditional EPS production lines usually rely on imported PLC for automatic control, but this mode has problems such as strong technical dependence, high maintenance costs, and high supply chain risks. Sinsegye optimized the control system for the EPS production line of a certain steel enterprise, replacing the original imported brand PLC with the self-developed SX21 series iComputer, successfully achieving domestic substitution of hardware and operating system.

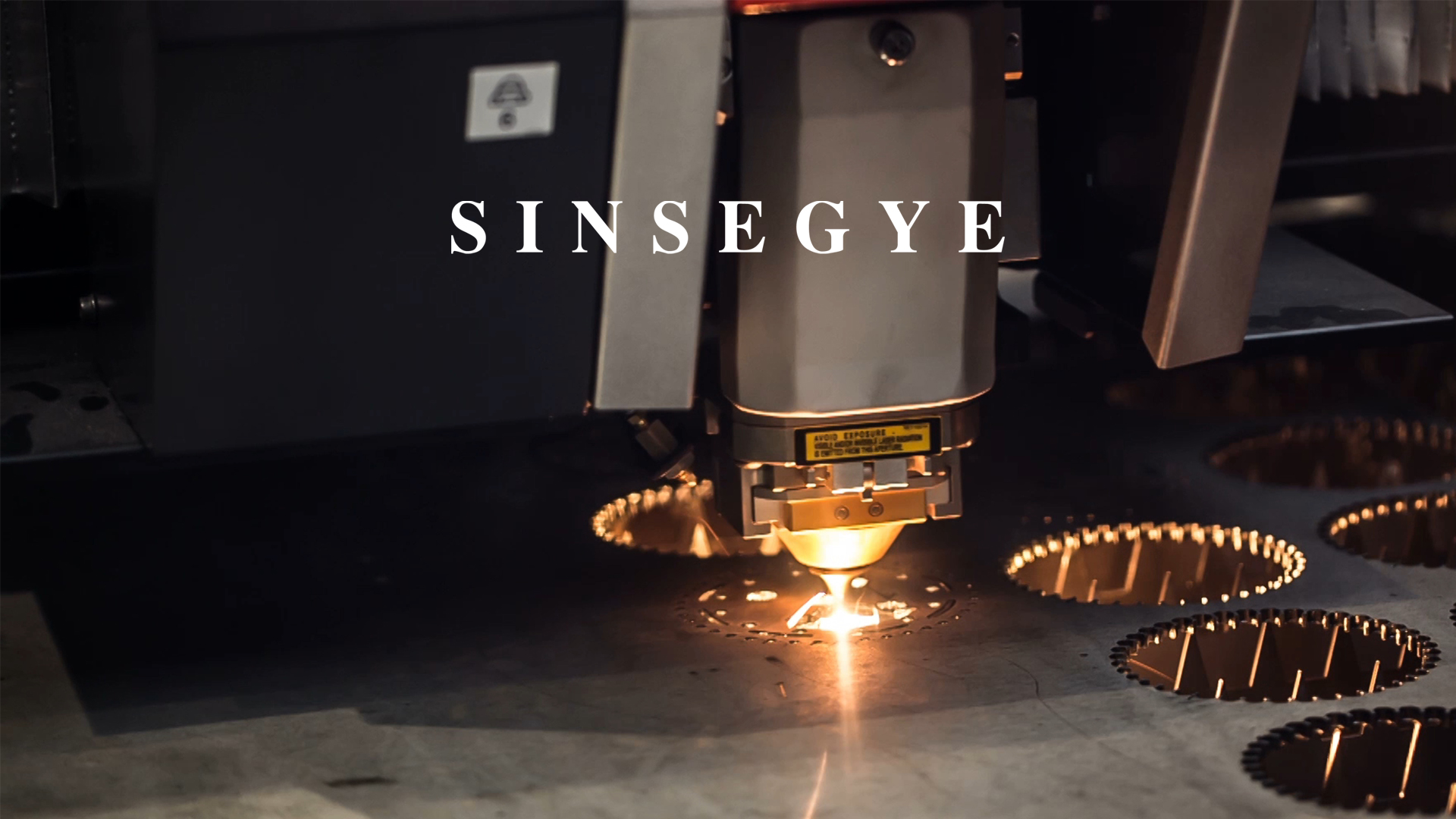

Six axis robot

With the rapid development of intelligence, automation, and information technology, the deep integration of robot technology and laser technology has brought unprecedented development opportunities for robot laser cutting technology. This technology can not only significantly improve production efficiency, but also reduce labor costs while ensuring processing quality.

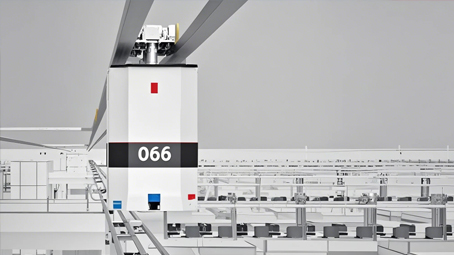

Overhead Hoist Transport

The semiconductor OHT (overhead hoist transport) equipment is the core automated handling system in the semiconductor manufacturing process, which realizes the intelligent transportation of key materials such as wafers and chips through elevated tracks.However, with the rapid development of the semiconductor manufacturing industry, OHT equipment is facing a series of new challenges and demands in terms of control systems.

Medium thick mirror detection equipment

In the precision optical manufacturing industry, quality inspection of optical lenses is a crucial step. Traditional detection methods often suffer from issues such as insufficient accuracy and low efficiency, making it difficult to meet the dual demands of modern production for high quality and efficiency. Especially for the thickness and defect detection of lenses, traditional equipment has obvious limitations in accuracy and classification ability.

Postal logistics sorting line

With the booming development of e-commerce and the growing logistics industry, the accuracy and efficiency of mail logistics sorting have become key factors affecting product quality, brand image, and customer satisfaction. However, the automated logistics sorting line under the traditional PLC control architecture is no longer able to meet the current application requirements in terms of efficiency, stability, and data accuracy. Therefore, developing a logistics sorting ......

Silicon steel sheet cutting machine

In the field of electrical equipment manufacturing, precise sorting and positioning of silicon steel sheets is a key link in improving production efficiency and product quality. With the continuous advancement of intelligent manufacturing technology, traditional manual operations and single automated equipment are no longer able to meet modern efficient and flexible production needs.

Intelligent monitoring of offshore platform equipment

As a key energy harvesting and processing facility, offshore platforms' dynamic equipment is subjected to severe tests such as harsh sea conditions, strong winds, huge waves, and seawater corrosion. These extreme environments not only weaken the mechanical integrity of platform equipment, but may also lead to serious accidents and energy supply disruptions. To address these challenges, CNOOC urgently needs a method that can monitor the condition of platform.......

energy storage coordination controller

In the rapid development of the global new energy industry, China has become a leader with its market size and technological iteration. The rise of new energy power stations, especially large-scale energy storage power stations, has triggered an urgent need for efficient and safe management. The number of energy storage inverters (PCS) in energy storage power plants has surged, and traditional AGC/AVC regulation systems are insufficient to cope with fluctuations,......

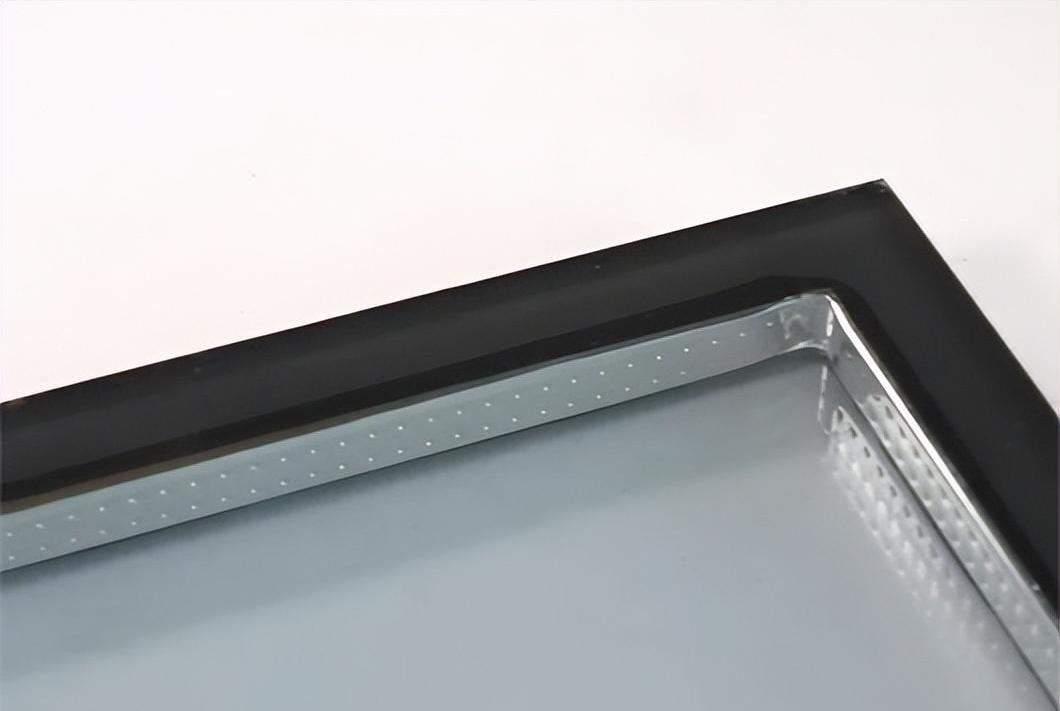

High speed point butyl rubber equipment

The high-speed point butyl rubber equipment uses a precisely controlled butyl rubber coating system to evenly coat a layer of butyl rubber layer around the glass, achieving excellent sealing effect. This device integrates three core modules: butyl rubber coating system, flow stabilization control and metering control system, and automated coating and transmission control system, ensuring the accuracy and correctness of the coating process.

Four axis column robotic arm

With the development of technology and the maturity of automation technology, robot technology is gradually penetrating into various industries, leading the transformation of production methods. In the highly competitive automation engineering industry, improving production efficiency, ensuring the continuity and stability of the production process......