-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

Servo motors are integral components in modern automation, robotics, and industrial applications, known for their precision control and efficiency. According to a report by ResearchAndMarkets, the global servo motor market is projected to reach USD 11.52 billion by 2025, growing at a CAGR of 7.3% from 2019 to 2025. This remarkable growth highlights the increasing adoption of servo motors across various sectors, including aerospace, automotive, and manufacturing, due to their ability to provide high performance and reliability. Despite their prevalence, many individuals and even professionals may not be aware of the incredible capabilities and diverse applications of servo motors. In this blog, we will uncover five amazing facts that shed light on the sophistication and versatility of these essential devices, which continue to drive innovation and efficiency in numerous fields.

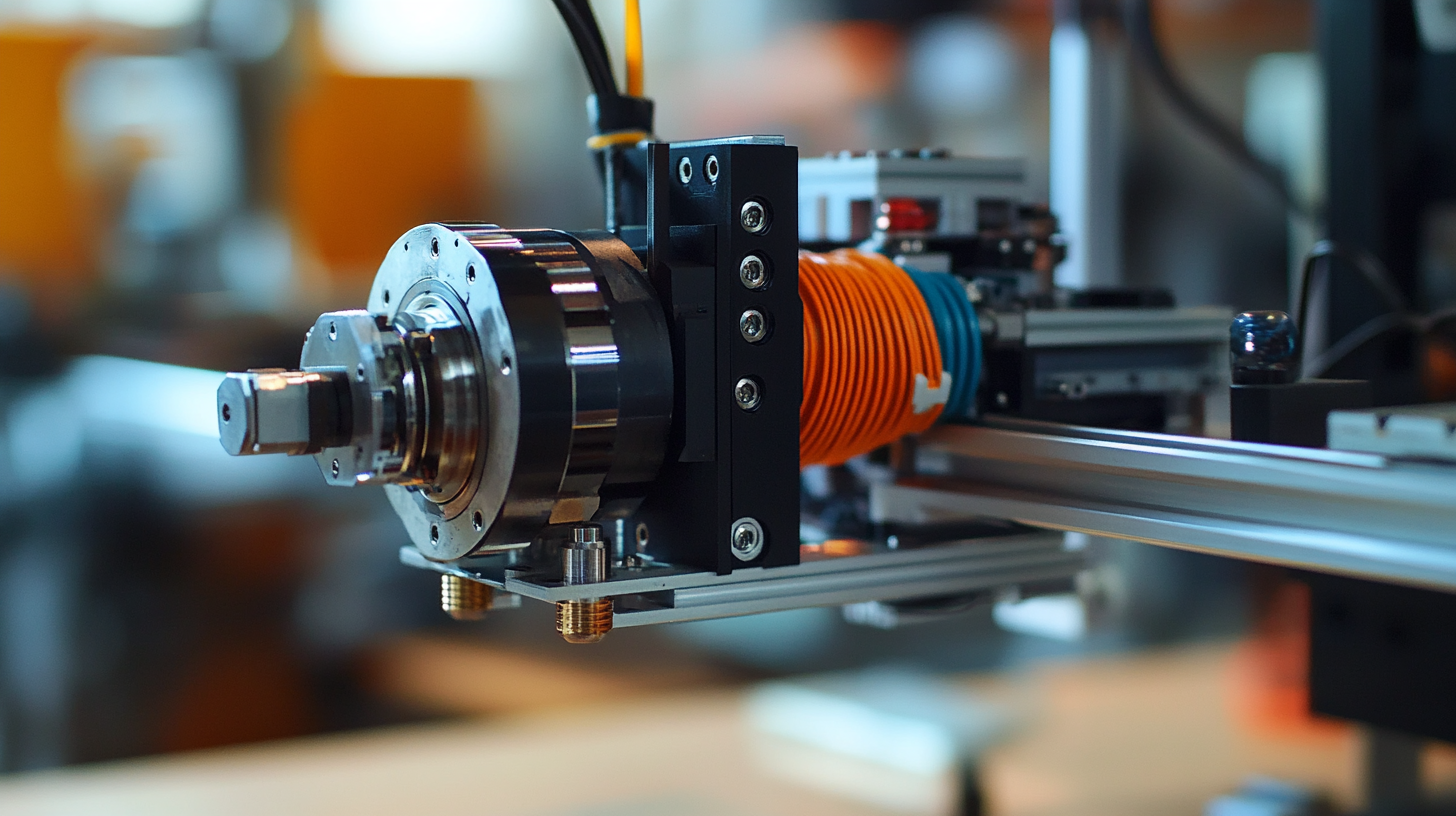

Servo motors play a crucial role in the realm of modern robotics, providing precise control and exceptional performance that are essential for advanced robotic systems. Unlike traditional DC motors, servo motors are designed for high efficiency and accurate positioning, making them ideal for applications where precise movements are necessary. This characteristic is particularly beneficial in fields like manufacturing automation, where robots need to perform delicate tasks such as assembly, painting, or welding with pinpoint accuracy.

Moreover, the versatility of servo motors allows them to be utilized in a wide array of robotic applications, from industrial robots that handle heavy machinery to small robotic arms used in research and development. Their ability to respond quickly to changing conditions and maintain stability under varying loads enhances the performance and reliability of robotic systems. Additionally, with advancements in technology, the integration of intelligent control algorithms with servo motors is paving the way for smarter robots capable of learning and adapting to their environments. As we continue to innovate, servo motors will undoubtedly remain at the forefront of robotic development, driving the evolution of automation and beyond.

| Fact | Description | Application |

|---|---|---|

| Precision Control | Servo motors provide highly accurate control over position, velocity, and acceleration. | Used in robotics to ensure precise movements. |

| Feedback Mechanism | Most servo motors incorporate feedback systems to enhance performance. | Common in CNC machines for accurate machining. |

| Compact Size | Servos are small and powerful, fitting into tight spaces. | Ideal for drones and small robotic arms. |

| Versatile Applications | Used in a wide variety of machines beyond robotics, including cameras and conveyor systems. | Found in automated assembly lines and robotic surgery. |

| Energy Efficiency | Servo motors consume less power compared to other motor types for similar performance. | Incorporated into energy-saving devices and electric vehicles. |

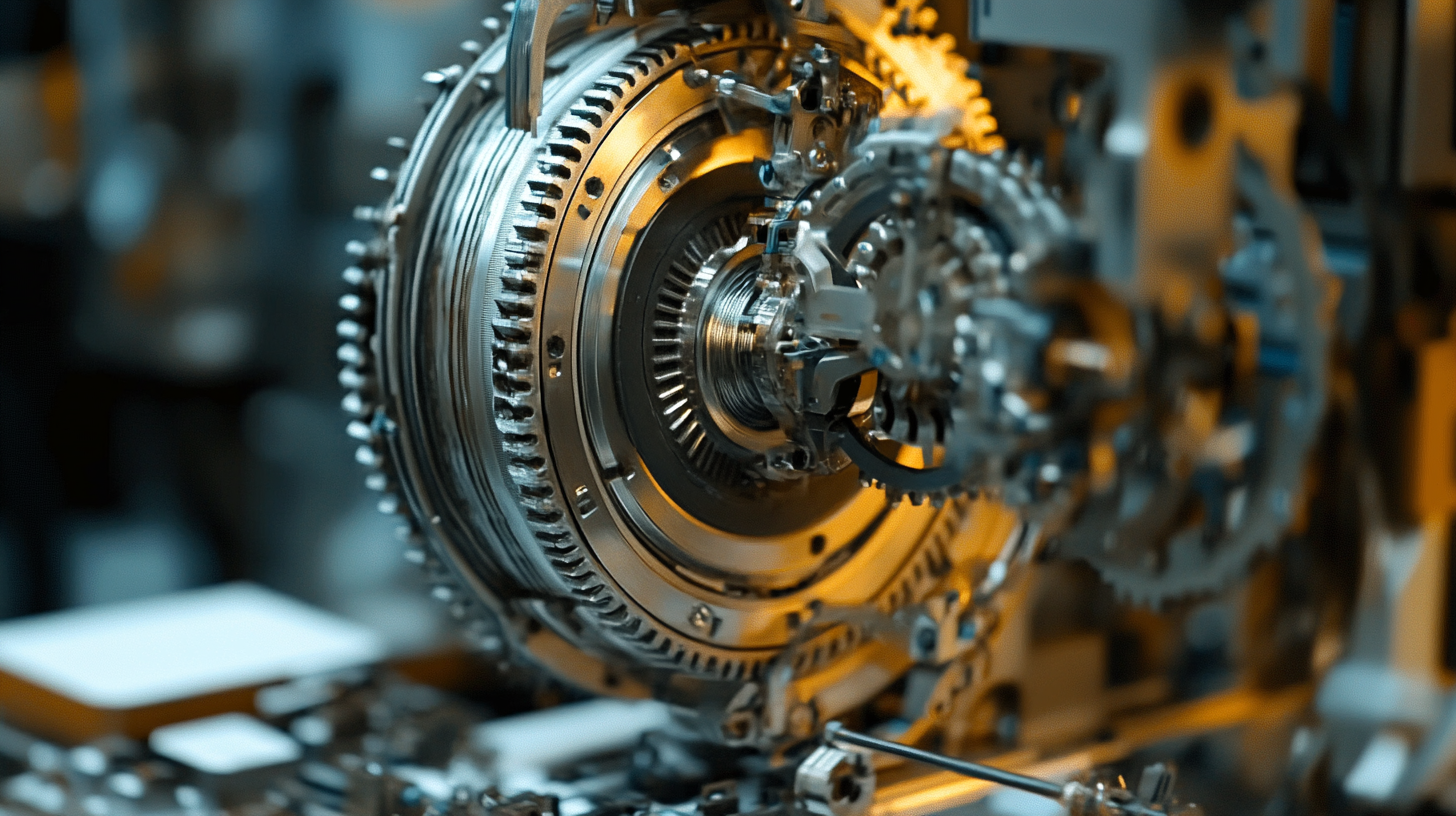

Servo motors are pivotal in achieving precise movements in various applications, from robotics to aerospace. Their ability to manage exact positioning stems from their intricate feedback systems, which allow real-time adjustments based on the motor's position. According to a report by MarketsandMarkets, the servo motor market is projected to reach $8.5 billion by 2025, underscoring the growing demand for precision-engineered systems that rely on these motors.

The precision of servo motors can be attributed to the combination of their high-quality feedback sensors and advanced control algorithms. With resolutions reaching up to 0.01 degrees in some industrial applications, servo motors can perform intricate tasks that require flawless accuracy. This capability is enhanced by digital signal processors that continually monitor and adjust performance, making them indispensable in sectors where precision is non-negotiable, such as automotive manufacturing and medical equipment.

Moreover, the adaptability of servo motors to different operational environments contributes significantly to their precision. They can be integrated with various encoders and controllers to meet specific performance criteria, ensuring that they can operate smoothly even under demanding conditions. As industries continue to embrace automation, the role of servo motors in achieving exact movements will only become more vital, reinforcing their importance in modern engineering and manufacturing processes.

This bar chart illustrates the efficiency and precision levels of different types of servo motors. The data showcases how various servo motors perform in terms of accuracy, speed, torque, and control response.

Servo motors are essential components in various applications, thanks to their precision and control capabilities. Broadly categorized into three types—DC servo motors, AC servo motors, and stepper motors—each type has its unique advantages. DC servo motors provide excellent speed control and are commonly used in applications requiring rapid response and high torque, such as robotic arms and CNC machines. On the other hand, AC servo motors are known for their high efficiency and durability, making them ideal for industrial automation, conveyor systems, and precision positioning systems.

Stepper motors, although not traditional servo motors, perform similarly by dividing a full rotation into equal steps. This characteristic makes them perfect for applications like 3D printers, laser cutters, and camera platforms, where precise movement and control are paramount. By understanding the capabilities and applications of these different types of servo motors, engineers can select the best option to meet their specific requirements, enhancing performance and efficiency in a wide range of industries.

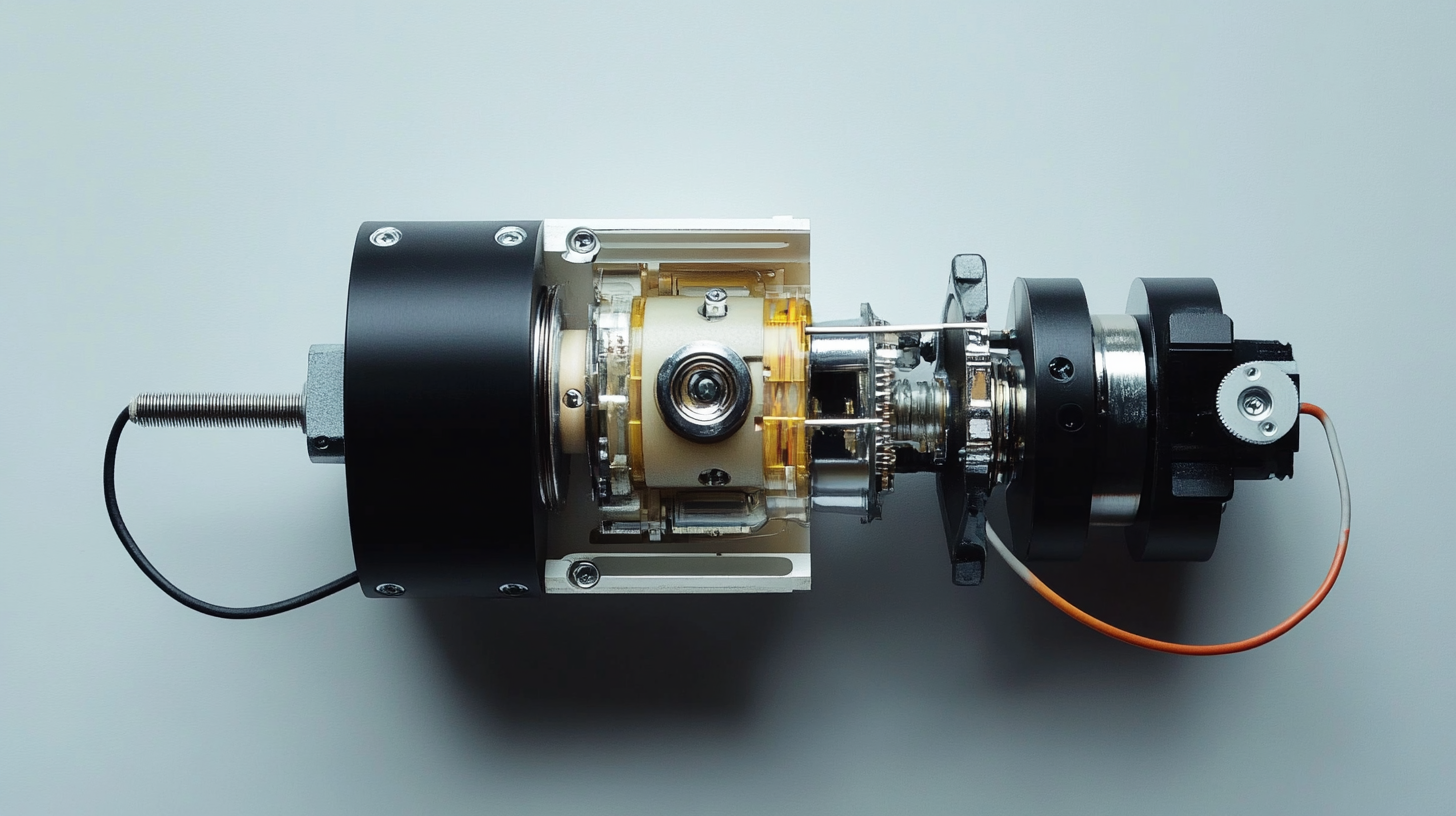

Servo motors are increasingly recognized not only for their precision and performance but also for their significant energy efficiency, which has a positive environmental impact. By utilizing closed-loop control systems, servo motors adjust their operation dynamically according to load requirements. This means they consume only the energy necessary to perform their tasks, unlike traditional motors that tend to draw constant power regardless of the demand. As a result, industries employing servo motors can reduce energy consumption substantially, leading to lower carbon emissions and a smaller ecological footprint.

Moreover, the ability of servo motors to operate efficiently runs parallel with the global push for greener technologies. In manufacturing settings, the reduction in energy consumption translates into lower operational costs, making servo motors a financially viable option while contributing to environmental sustainability. The application of servo motors in automated processes can optimize production times and minimize waste, thus fostering more sustainable practices in various sectors, from automotive to electronics. Emphasizing energy efficiency not only benefits the bottom line for businesses but also aligns with the growing need to protect our planet for future generations.

The future of servo motor technology in the industry is shaped by innovative trends that promise to enhance performance, efficiency, and application versatility. As automation continues to evolve, servo motors are becoming smarter and more integrated with advanced control systems. The increasing adoption of Industry 4.0 principles is driving the development of servo motors that can communicate in real-time, allowing for dynamic adjustments and improved operational precision. This connectivity not only enhances performance but also contributes to predictive maintenance strategies, reducing downtime and maintenance costs.

Another significant trend is the miniaturization of servo motors without compromising on their robust functionalities. As machines become more compact and integrated, the demand for smaller, high-performance servo motors is on the rise. This trend is pushing manufacturers to innovate, leading to the use of advanced materials and design techniques that enable higher torque density in smaller footprints. Furthermore, energy efficiency is becoming a focal point; the development of brushless and more efficient motor designs helps industries lower their energy consumption while maintaining performance standards. With these advancements, servo motors are set to play a crucial role in the future of automation and robotics, paving the way for smarter manufacturing environments.

This pie chart illustrates the key benefits of servo motors that contribute to their innovative applications in the industry, showcasing their high precision, energy efficiency, and wide range of applications.