-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In today's rapidly evolving industrial landscape, the adoption of automation technologies is not just advantageous but essential for optimizing operational efficiency. According to recent reports from the International Society of Automation, nearly 75% of manufacturers reported significant performance improvements after implementing advanced automation solutions. Among these innovations, Direct Automation PLC (Programmable Logic Controller) stands out as a critical player in transforming traditional manufacturing processes into streamlined, efficient systems. By integrating Direct Automation PLC solutions, industries are not only enhancing productivity but also reducing operational costs and minimizing human error. As we delve into the seven best Direct Automation PLC solutions, we will explore how these technologies are reshaping the future of industrial operations and providing businesses with a competitive edge in an increasingly automated world.

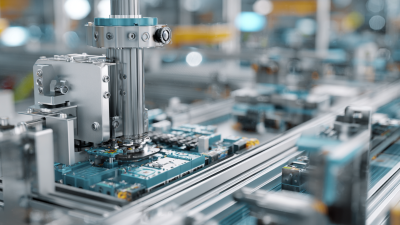

The adoption of Programmable Logic Controllers (PLCs) has transformed the landscape of industrial automation, positioning them as a crucial element in enhancing manufacturing efficiency. PLCs are designed to automate complex processes and improve operational reliability, enabling manufacturers to streamline workflows and reduce downtime. By integrating PLC systems, industries can achieve real-time monitoring and control over their operations, leading to quicker decision-making and enhanced productivity.

Moreover, PLCs contribute significantly to reducing human error, which is often a source of inefficiency in manufacturing settings. Through advanced programming capabilities, PLCs can execute repetitive tasks with high precision, minimizing the risk of mistakes that arise from manual intervention. This automation not only speeds up production lines but also ensures consistent quality in the end products. As industries strive to reduce operational costs while maximizing output, the implementation of PLC solutions proves to be a smart investment in the pursuit of sustainable growth.

When exploring the best direct automation PLC solutions for industrial operations, it's essential to consider the key features that set leading systems apart. One of the most significant features is modular architecture, allowing for easy scalability and customization. This flexibility enables businesses to adapt their automation systems to evolving production needs without significant downtime or redesign costs. Moreover, top-tier PLC solutions often prioritize user-friendly interfaces, facilitating seamless integration and operation for both seasoned engineers and new operators.

Another vital feature to look for is robust communication capabilities. Leading PLCs support various communication protocols, ensuring compatibility with existing machinery and third-party devices. This interoperability enhances the overall efficiency of industrial operations, as data can be shared and analyzed in real time, leading to informed decision-making and quicker response times to production anomalies. Additionally, advanced diagnostic tools embedded within these PLC systems help in quickly identifying and resolving issues, minimizing production interruptions. By focusing on these key aspects, businesses can select automation solutions that significantly enhance their operational efficiency and reduce overhead costs.

This chart represents the key features of various direct automation PLC solutions based on their effectiveness in optimizing industrial operations.

In the rapidly evolving landscape of industrial automation, selecting the right Programmable Logic Controller (PLC) solution can significantly enhance operational efficiency. With the global machinery and industrial automation market projected to reach USD 407.4 billion by 2032 at an 8.2% CAGR, businesses are increasingly turning to advanced PLC solutions to stay competitive. This comparative analysis highlights the top seven direct automation PLC solutions that can streamline processes, reduce downtime, and optimize productivity in manufacturing settings.

Emerging technologies such as Micro and Nano PLCs are also making waves in the market, catering to niche applications with their compact size and flexibility. Research suggests that the Micro and Nano PLC market could see significant growth from 2025 to 2035, driven by rising demand for automation in small-scale operations. Additionally, the Virtual PLC and Soft PLC segments are expected to thrive, with projections indicating a market reach of USD 3.7 billion by 2035. These advancements not only improve operational efficiency but also provide a cost-effective approach to industrial automation, making them viable options for diverse manufacturing needs.

The manufacturing sector is undergoing a significant transformation as direct automation gains traction. This shift is not merely a trend but a strategic response to the increasing demand for efficiency, accuracy, and speed in production processes. Direct automation integrates advanced technologies, such as PLC systems, robotics, and IoT devices, enabling manufacturers to streamline operations and reduce reliance on manual labor. As a result, companies are experiencing enhanced productivity and improved operational reliability, allowing them to stay competitive in a fast-paced market.

Moreover, as industries strive to achieve greater sustainability, direct automation proves to be a game-changer. By optimizing resource use and minimizing waste, automated systems contribute to greener production practices. This alignment with sustainability goals not only meets regulatory requirements but also resonates with consumers who prioritize environmentally responsible practices. As manufacturers pivot towards direct automation, they are not only adopting advanced technologies but also fostering a culture of innovation that is essential for long-term success in the evolving industrial landscape.

In today's competitive industrial landscape, the impact of PLC (Programmable Logic Controller) technology on production downtime and operational costs cannot be overstated. PLCs play a crucial role in automating processes, reducing the likelihood of human error, and ensuring system reliability. By implementing advanced PLC solutions, businesses can significantly minimize production interruptions, which directly translates to cost savings.

One of the effective tips for leveraging PLC technology is to conduct regular system audits. Regular checks can help identify potential issues before they lead to downtime. Furthermore, investing in a robust PLC maintenance program can extend the lifespan of your equipment, ensuring consistent performance. Ensuring that your staff is adequately trained on the latest PLC systems also enhances operational efficiency and minimizes costly errors.

Another important aspect is integrating real-time monitoring with PLC systems. This allows operators to track performance metrics and receive alerts about anomalies instantly. Such proactive measures not only help in swiftly addressing potential failures but also aid in optimizing workflows, ultimately resulting in lowered operational costs and improved productivity.