-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In today's rapidly evolving manufacturing landscape, the integration of advanced automation systems has become imperative for achieving operational efficiency and enhancing productivity. Among the various technologies available, the Mitsubishi Servo Motor stands out as a cornerstone of modern automation. According to a report by MarketsandMarkets, the global servo motor market is projected to reach USD 14.89 billion by 2026, driven largely by the increasing demand for precision and reliability in automated processes. Mitsubishi Servo Motors offer distinct advantages, such as high-speed performance, precise control, and energy efficiency, which are vital for achieving competitive advantages in industries ranging from automotive to electronics. As manufacturers seek to optimize their operations, understanding the benefits of incorporating Mitsubishi Servo Motors into their automation systems becomes essential for driving innovation and sustaining growth in a challenging economic environment.

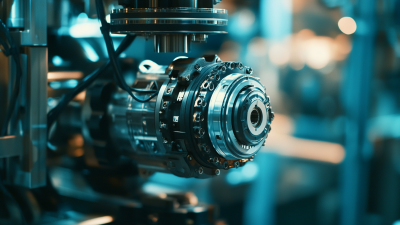

Mitsubishi servo motors are emerging as a preferred choice in modern automation systems, offering key benefits that enhance operational efficiency and productivity. One of the primary advantages is their high precision and superior control capabilities, which are essential in applications that require exact positioning and speed regulation. This precision translates to reduced error rates in manufacturing processes, making them particularly valuable in industries such as automotive, electronics, and robotics.

In addition to precision, these servo motors are known for their robustness and reliability, supporting uninterrupted operation in demanding environments. Their compatibility with advanced technologies such as IoT, AI, and data analytics further amplifies their utility in automation solutions, allowing for smoother integration and smarter performance monitoring. As companies worldwide embrace digital transformation, the demand for efficient and reliable automation solutions continues to rise, positioning Mitsubishi servo motors as a critical component in driving innovation and operational excellence across various sectors.

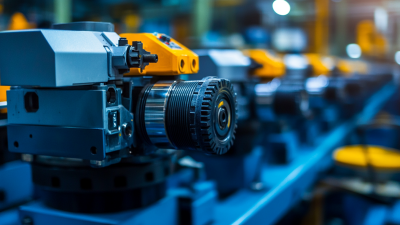

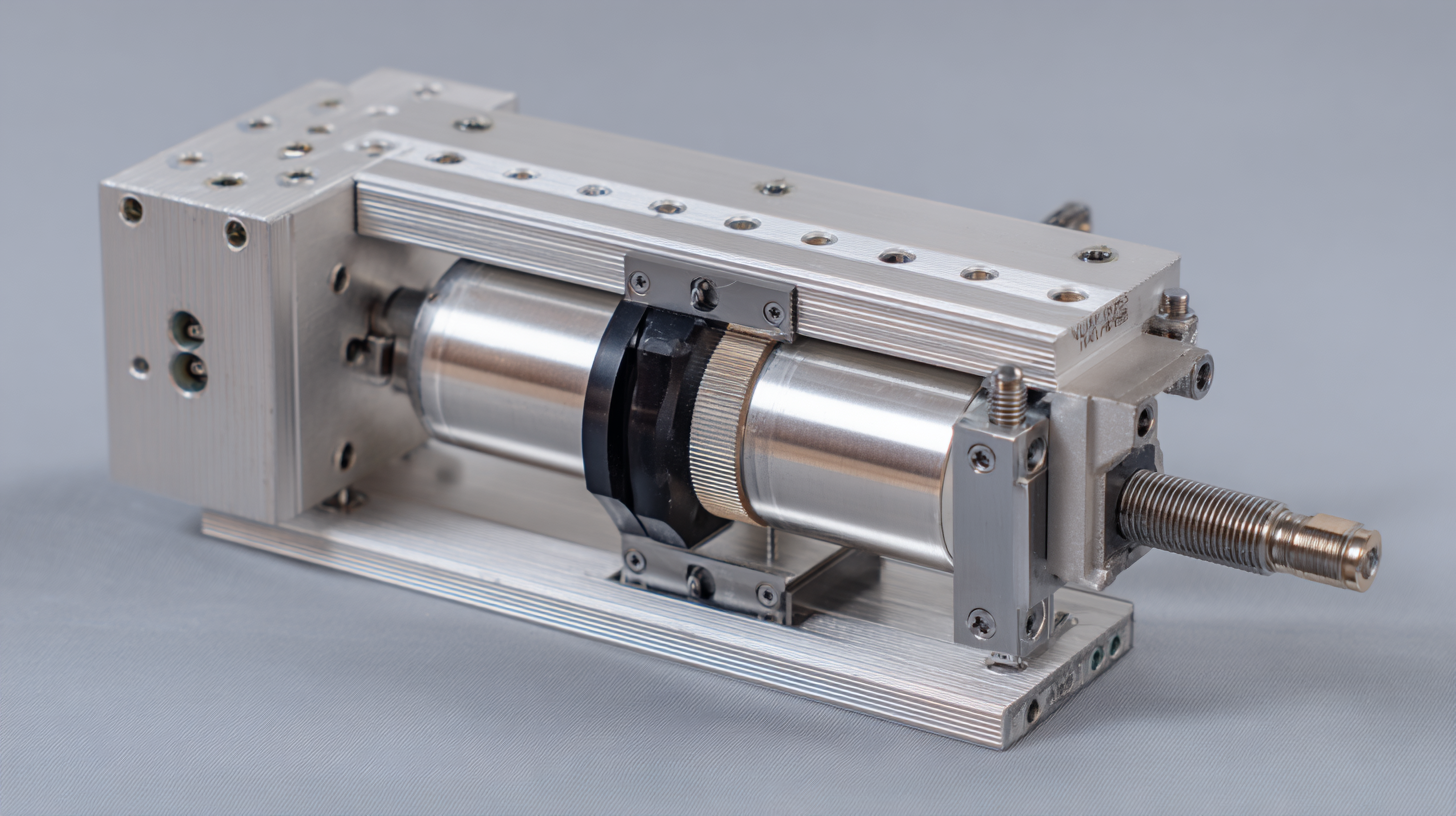

When selecting the right Mitsubishi servo motor for your application, it’s crucial to consider various factors that can impact performance and efficiency. Firstly, evaluate the specific requirements of your automation system, including load capacities, speed, and torque. Mitsubishi offers a diverse range of servo motors, from compact models suitable for small machinery to high-torque versions for more demanding applications. Clearly defining your operational needs will help you narrow down the options.

Additionally, compatibility with your existing control systems is another essential consideration. Mitsubishi servo motors are designed to work seamlessly with their PLCs and controllers, ensuring optimal performance. It's advisable to assess the communication protocols and feedback systems to ensure they align with your setup. Finally, don’t overlook the importance of support and documentation; having access to comprehensive resources can simplify the integration process and aid in troubleshooting, ultimately leading to a more efficient automation solution.

Integrating Mitsubishi servo motors into existing automation systems offers a myriad of benefits, enhancing both performance and efficiency. These motors are renowned for their precision and responsiveness, making them ideal for applications that require high accuracy and speed. When integrating these servo motors, it’s essential to assess the current system’s compatibility and identify areas where performance can be improved.

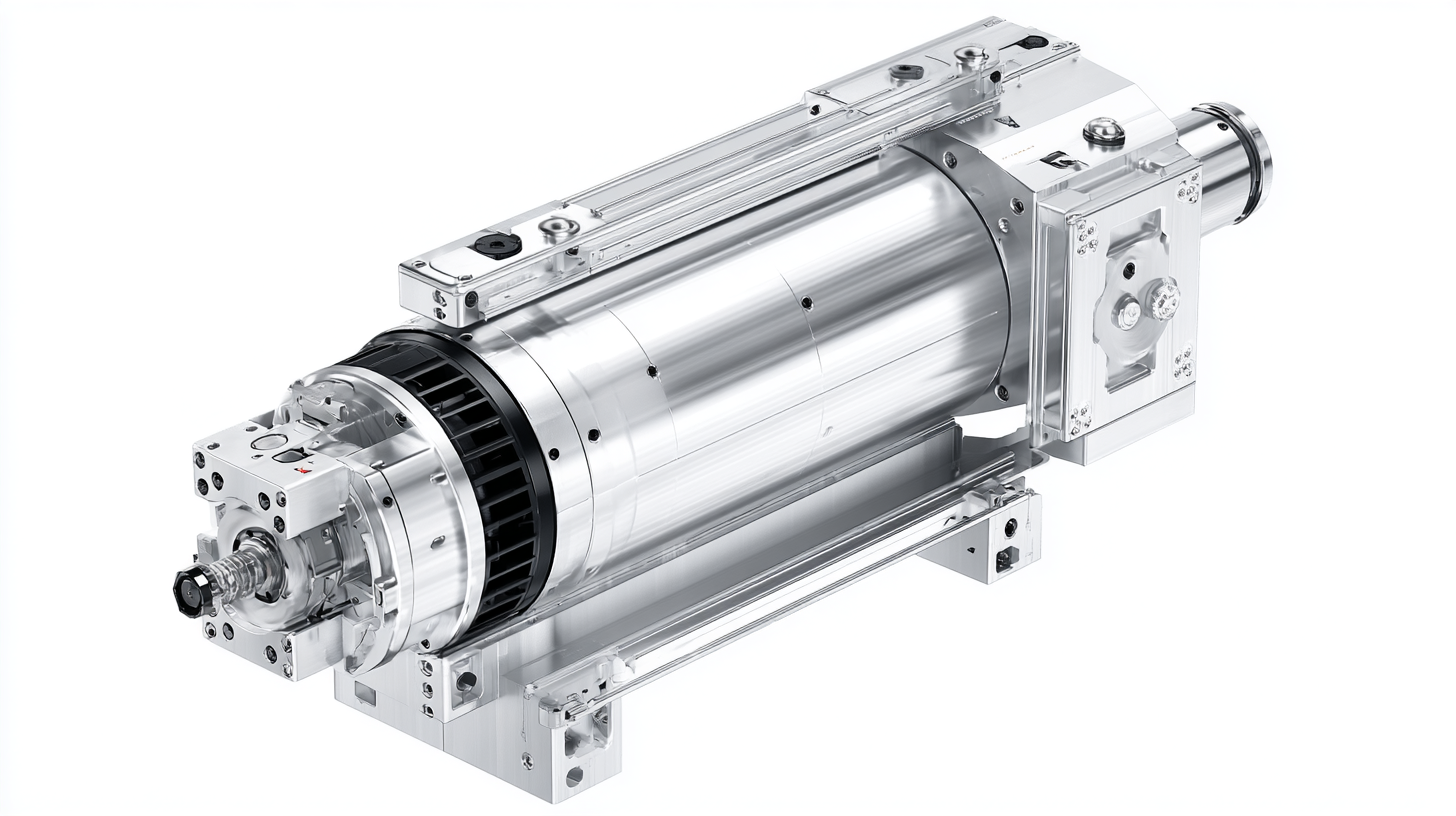

Mitsubishi servo motor technology is at the forefront of enhancing performance in modern automation systems. These motors provide exceptional precision and speed, allowing for intricate control over various applications. With features like high torque density and rapid acceleration capabilities, Mitsubishi servo motors can meet the demanding requirements of industries such as robotics, manufacturing, and material handling. This precision enables manufacturers to optimize production processes, minimize waste, and enhance overall efficiency.

Moreover, the advanced feedback systems integrated within Mitsubishi servo motors facilitate real-time monitoring and adjustment, ensuring consistent performance under varying operational conditions. This level of adaptability is crucial in modern automation, where flexibility is paramount. Additionally, the robust design of Mitsubishi servo motors contributes to their reliability and longevity, reducing maintenance costs and downtime.

By leveraging such advanced technology, businesses can achieve significant improvements in their production rates and product quality, solidifying Mitsubishi’s position as a leader in servo motor innovation for automation.

When integrating servo motors into modern automation systems, it is crucial to prioritize maintenance practices to ensure longevity and optimal performance. The increasing market demand for industrial motors, projected to reach USD 27.0 billion by 2035, highlights the importance of efficient and reliable motor systems. Among the best practices for maintaining servo motors is regular inspection and calibration. This proactive approach can help identify issues before they escalate, ultimately minimizing downtime and enhancing productivity.

Another valuable tip is implementing a consistent lubrication schedule. Proper lubrication reduces friction and wear, which is vital for the efficient operation of servo motors. Additionally, staying informed about the latest technical support services can provide immediate assistance when facing operational challenges. For instance, continuous support services are now more prevalent, ensuring that users have access to expert help 24/7.

Finally, using diagnostic tools to monitor motor performance can help in recognizing patterns that may indicate impending failure. By embracing these maintenance best practices, organizations can maximize their investment in automation technology while ensuring that their systems remain responsive and efficient in today's competitive landscape.

| Feature | Description | Advantages |

|---|---|---|

| High Precision | Provides accurate position control and speed regulation. | Enables improved quality in manufacturing processes. |

| Compact Design | Available in various compact forms suitable for limited spaces. | Facilitates integration into existing systems without extensive redesign. |

| Energy Efficiency | Optimized power consumption to reduce operational costs. | Lowers energy bills and contributes to sustainable practices. |

| Durability | Built to withstand harsh environments and continuous operation. | Reduces downtime and maintenance needs. |

| Easy Integration | Compatible with various automation systems and protocols. | Speeds up deployment and reduces setup times. |

| Comprehensive Support | Access to technical resources and customer support. | Enhances user experience and troubleshooting efficiency. |