-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In recent years, the demand for Linear Motor Actuators has surged, primarily driven by advancements in automation and robotics across various industries. According to a recent market research report by MarketsandMarkets, the global linear motor market is projected to grow from USD 4.6 billion in 2022 to USD 7.8 billion by 2027, showcasing a compound annual growth rate (CAGR) of 10.7%. This remarkable growth can be attributed to the need for high precision and efficiency in applications such as CNC machinery, packaging, and material handling. As global buyers seek to enhance their operational performance, exploring alternative solutions to traditional linear motor actuators has become essential. This blog will delve into various types of linear motor actuators, their applications, and how these innovations can meet the diverse needs of industries striving for excellence in automation.

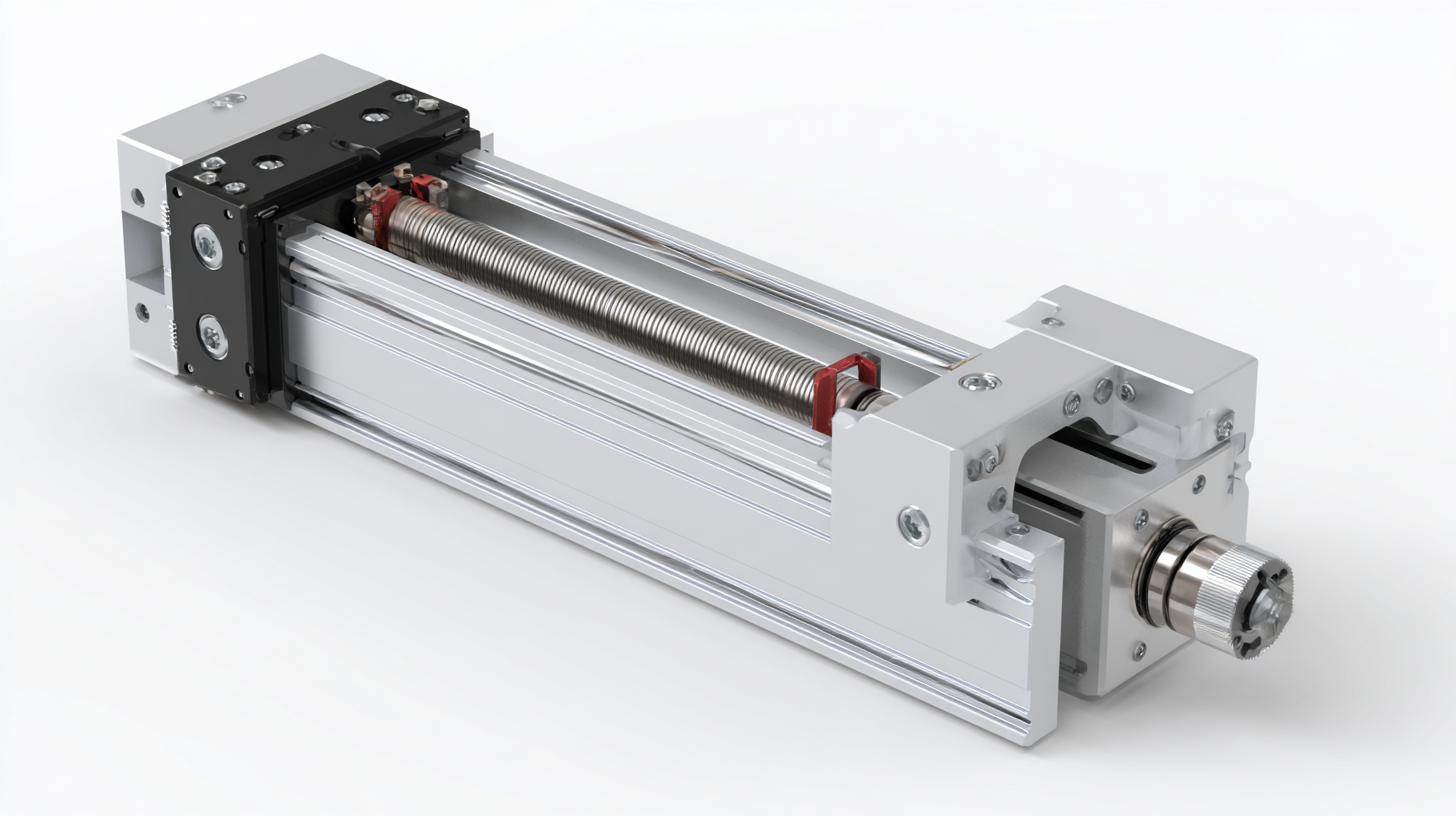

Linear motor actuators are essential components in various motion control applications, enabling precise movement and automation. Understanding their basic functions is crucial for global buyers seeking the best solutions for their unique needs. A linear motor actuator operates on the principles of electromagnetism, converting electrical energy into linear motion, which is vital for tasks ranging from industrial automation to robotics.

Recent developments in electric actuators highlight the importance of keeping up with the latest technology to make informed purchasing decisions. For instance, advancements in servos, crucial components for motion control systems, provide improved functionalities and efficiencies. The expansion of linear motion products is also significant, as it addresses the diverse requirements of various industries, necessitating a thorough grasp of actuator types and specifications. Buyers must consider these evolving technologies to select the best linear motor actuator that meets their operational demands.

This chart provides a performance comparison of various linear motor actuators based on their maximum speed capabilities. Understanding these differences is crucial for selecting the right actuator for specific applications.

When selecting a linear motor actuator, several key factors must be considered to ensure the best fit for your application. First, the performance characteristics such as speed, force, and precision are crucial. Research shows that users often prioritize these specifications based on their operational requirements, with a significant percentage indicating that precision is non-negotiable, especially in applications like robotics and automation. For instance, an actuator with a high stiffness-to-weight ratio can improve performance in soft robotics, which is gaining traction for its flexibility and adaptability.

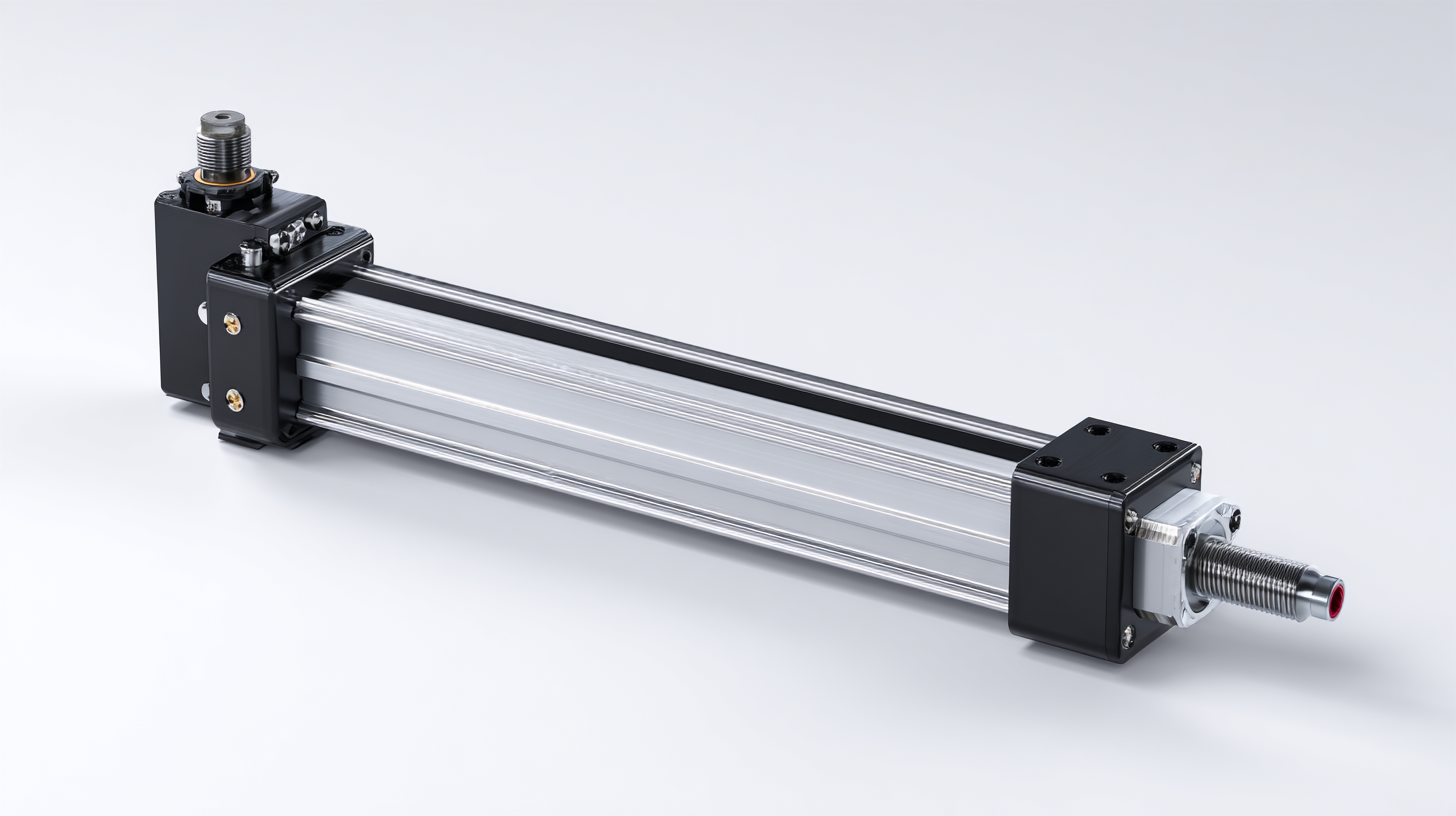

Another essential factor is the compatibility with existing systems and the ease of integration. The transition from traditional hydraulic systems to electric actuators, for example, is being embraced in various industrial sectors. A recent industry report highlights that companies adopting electric actuators experience up to 30% efficiency improvements when compared to their hydraulic counterparts. This increased efficacy often comes with reduced maintenance costs and greater reliability, making electric linear actuators an attractive alternative for global buyers looking to modernize their operations.

As industries evolve, the need for innovative technologies in actuation systems becomes paramount. While linear motor actuators have established themselves as reliable solutions, it's essential to explore alternative technologies that can meet diverse operational requirements. Systems such as pneumatic and hydraulic actuators offer unique benefits in specific applications, providing the power and precision necessary for heavy-duty tasks. Additionally, technologies like piezoelectric actuators and voice coil motors present advantages in terms of size and responsiveness, making them ideal for precise movement in compact environments.

Furthermore, the integration of smart technologies into actuator systems is transforming the landscape. Electromechanical systems equipped with advanced sensors and IoT capabilities allow for real-time monitoring and control, leading to increased efficiency and reduced downtime. As global buyers consider their options, understanding the full spectrum of available actuator technologies—and their respective applications—becomes crucial in making informed decisions. This exploration of alternatives not only encourages innovation but also fosters a competitive edge in markets that demand reliability and adaptability.

When considering actuation methods for various applications, linear motor actuators stand out for their precision and efficiency. However, alternative solutions like pneumatic or hydraulic actuators have their merits in specific scenarios. Recent industry reports indicate that linear motor actuators provide positioning accuracy within ±0.01 mm, making them ideal for high-precision tasks, while pneumatic actuators can achieve rapid movements, albeit with less accuracy. A comparative analysis is essential to determine the best choice based on factors like application requirements, environment, and cost-effectiveness.

Tips: Always assess the operational environment of your application before choosing an actuator type. For example, pneumatic actuators excel in environments where rapid cycling is necessary, while linear motors are more suited for clean, controlled environments due to their minimal maintenance needs. Additionally, consider energy consumption; linear motor actuators typically offer lower energy costs over time compared to hydraulic systems, which can require significant energy input for operation.

Ultimately, the decision should be data-driven, referencing reliable market analyses that outline the performance specifications and applications of each actuator type. By keeping an eye on industry trends and technological advancements, buyers can make informed decisions tailored to their specific needs.

| Actuation Method | Force Output (N) | Speed (m/s) | Precision (mm) | Cost Efficiency ($/N) | Maintenance Requirements |

|---|---|---|---|---|---|

| Linear Motor Actuator | 100 | 2.5 | 0.01 | 0.5 | Low |

| Hydraulic Actuator | 150 | 1.5 | 0.1 | 0.7 | Moderate |

| Pneumatic Actuator | 80 | 3.0 | 0.05 | 0.6 | High |

| Electric Rotary Actuator | 120 | 2.0 | 0.02 | 0.4 | Low |

| Stepper Motor | 60 | 1.0 | 0.02 | 0.3 | Very Low |

The global market for linear motor actuators is evolving rapidly, driven by advancements in technology and increasing demand across various industries. Buyers are now exploring alternative solutions that not only enhance performance but also offer cost-effectiveness and sustainability. As companies seek greater efficiency in automation and precision in applications, the need for versatile linear motor actuators becomes evident. These components, known for their superior positioning capabilities and reduced maintenance requirements, are transforming production lines and enhancing operational capabilities.

Future directions for buyers in this sector indicate a shift towards integrating smart technologies with linear motor actuators. The incorporation of IoT and AI technologies allows for real-time monitoring and predictive maintenance, minimizing downtime and enhancing reliability. Additionally, there is a growing interest in eco-friendly alternatives, with manufacturers focusing on sustainable materials and energy-efficient designs. As the market continues to innovate, linear motor actuator buyers will benefit from a rich array of choices tailored to meet their specific operational challenges, ensuring they remain competitive in an increasingly dynamic global landscape.