-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

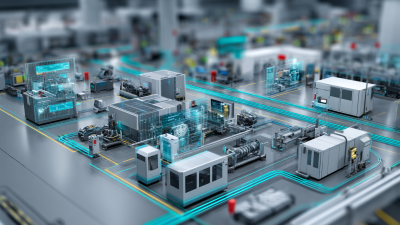

In the rapidly evolving landscape of modern industry, the integration of advanced technologies has become essential for enhancing productivity and efficiency. One such innovation that stands out is the Servo Motor Drive, a crucial component in numerous automated systems. As businesses strive for precision and adaptability, the applications of Servo Motor Drives continue to expand, transforming traditional manufacturing processes and enabling the development of smart factories. This blog will explore the top strategies for implementing Servo Motor Drives across various sectors, highlighting their role in optimizing performance, reducing operational costs, and improving product quality. With real-world examples and expert insights, we aim to provide a comprehensive understanding of how Servo Motor Drives are reshaping the industrial arena, driving forward the future of automation and manufacturing excellence.

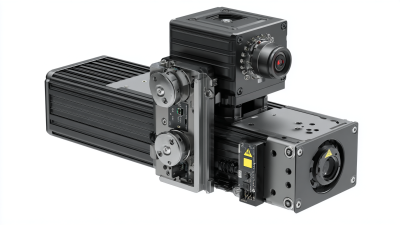

Servo motors play a crucial role in the advancement of robotics and automation, providing precision and efficiency in various applications. In modern industrial settings, servo motors are integral to robotic arms, enabling them to execute intricate tasks with unparalleled accuracy. By controlling the position, velocity, and torque with exceptional responsiveness, these motors enhance the functionality of robots used in assembly lines, packaging, and material handling. This level of control not only improves productivity but also minimizes the risk of errors, making them indispensable in high-stakes environments.

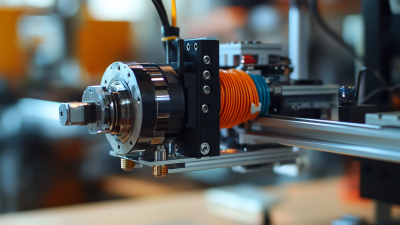

Moreover, servo motors facilitate seamless integration in automated systems where real-time feedback is essential. In scenarios like CNC machining and 3D printing, servo motors ensure that the machinery can adapt to dynamic conditions, resulting in superior adaptability and faster turnaround times. The ability to achieve high speeds while maintaining torque stability positions servo motors as a backbone for cutting-edge robotics solutions. As industries continue to embrace automation, the innovative applications of servo motors will undoubtedly drive the future of manufacturing and robotic technology.

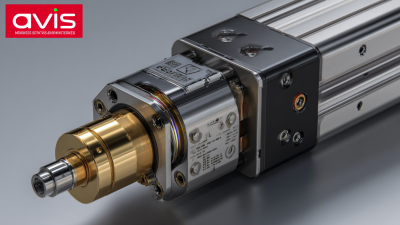

In modern industry, the transition toward energy-efficient alternatives has never been more critical. Traditional motor drives can be power-hungry and often lead to excessive energy consumption, which increases operational costs and harms the environment. Servo motor drives, which offer precision control and efficiency, are emerging as a transformative solution. Their ability to adjust speed and torque dynamically allows industries to optimize their operations while significantly reducing energy usage.

Tips: When considering the implementation of servo motor drives, assess your current systems for baseline energy consumption. This will help you identify potential savings and justify the upgrade investment. Additionally, ensure proper training for your engineering team on the complexities of servo systems; this can maximize both performance and energy efficiency.

Moreover, integrating servo motor drives can facilitate advanced automation and operational data collection, leading to further enhancements in productivity. As industries strive to achieve sustainability goals, these innovative systems present an attractive option to minimize both costs and energy footprints without compromising on performance.

Tips: Look into retrofitting existing machinery with servo technology to capitalize on energy savings without the need for complete replacements. Regular maintenance of servo systems will ensure they operate optimally, maintaining energy efficiency over time.

| Application Area | Servo Motor Type | Energy Savings (%) | Benefits | Notes |

|---|---|---|---|---|

| Robotics | AC servo motor | 30% | Improved precision and reduced wear | Ideal for assembly lines |

| CNC Machines | DC servo motor | 25% | Enhanced speed and control | Suitable for high-precision tasks |

| Conveyor Systems | Stepper motor | 20% | Lower operational costs | Efficient for intermittent motion |

| Printing Machinery | Direct drive motor | 35% | Reduced energy consumption | Minimized maintenance needs |

The innovative applications of servo motors are transforming manufacturing processes across various industries. As the global industrial automation market is projected to expand from $205.86 billion in 2022 to $395.09 billion by 2029, achieving a compound annual growth rate (CAGR) of 9.8%, the integration of advanced servo motor technology is pivotal. These motors provide high precision, efficiency, and flexibility, which are crucial for modern manufacturing needs.

In particular, servo motors are essential in automating processes for sectors such as aerospace, automotive, and consumer electronics. For instance, the emergence of hybrid solutions that integrate servo systems with traditional machinery leads to more efficient production lines and reduced operational costs. This is reflected in the recent advancements showcased during industry expos, where numerous new products were unveiled, highlighting the ongoing trend of incorporating servo motors for improved performance and reliability.

Moreover, industries are increasingly adopting servo motors to enhance product quality and manufacturing speeds. The ability of these motors to perform complex movements with precision allows manufacturers to push the boundaries of design and increase automation without compromising on quality. As we move toward a more automated future, the role of servo motors will only become more significant, driving innovation in manufacturing processes.

In modern industrial applications, precision control systems heavily rely on servo motors to enhance efficiency and accuracy. Servo motors provide a high degree of control over position, speed, and torque, which is essential in industries such as robotics, automotive, and manufacturing. According to a report by MarketsandMarkets, the global servo motor market is expected to grow from $9.4 billion in 2022 to $15.3 billion by 2027, reflecting an annual growth rate of over 10%. This surge highlights the pivotal role that precision control systems play in driving automation and improving operational workflows.

One of the key advantages of servo motors lies in their closed-loop control systems, which allow for real-time feedback and adjustments. This capability makes them indispensable in applications that require tight tolerance levels, such as CNC machining and assembly lines. Implementing servo motors can lead to significant reductions in cycle times and waste, ultimately improving production quality.

**Tips:** When integrating servo motors into your systems, ensure that you select the appropriate motor type based on your specific application requirements. Moreover, consider investing in advanced control algorithms to maximize performance and efficiency. Regular maintenance and calibration of servo systems are also crucial for sustained precision and longevity in your industrial operations.

In the realm of modern automation, the choice of drive technology significantly influences operational efficiency and productivity. When comparing servo motors with traditional drive technologies like stepper motors and DC drives, data shows that servo motors offer superior precision and speed control. According to a recent report by MarketsandMarkets, the global servo motor market is poised to reach $9.2 billion by 2025, growing at a CAGR of 6.3%. This growth is primarily driven by the increasing demand for high-performance motion control in various industries, including robotics and packaging.

Moreover, servo motors excel in applications requiring rapid acceleration and deceleration with minimal overshoot. For example, in CNC machining, the error margin in servo-controlled systems can be as low as ±0.01 mm, compared to stepper motors, which often face performance degradation under heavy loads. A study by the International Society of Automation noted that servo motors can improve energy efficiency by as much as 30% compared to traditional DC drives, emphasizing their relevance in industries striving for sustainability while maximizing output. These advancements position servo motors as the preferred option for many modern industrial applications.