-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

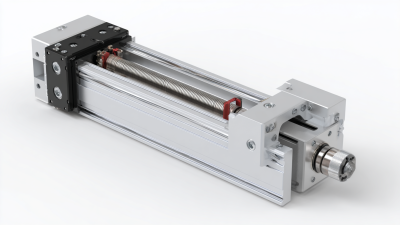

In the realm of modern automation solutions, the Linear Motor Actuator stands out as a pivotal component driving efficiency and precision in various applications. As industries strive for greater productivity and accuracy, the advantages offered by linear motor actuators become increasingly significant. These innovative devices convert electrical energy directly into linear motion, eliminating the need for traditional mechanical components such as gears and belts, which often introduce friction and limit performance.

In the realm of modern automation solutions, the Linear Motor Actuator stands out as a pivotal component driving efficiency and precision in various applications. As industries strive for greater productivity and accuracy, the advantages offered by linear motor actuators become increasingly significant. These innovative devices convert electrical energy directly into linear motion, eliminating the need for traditional mechanical components such as gears and belts, which often introduce friction and limit performance.

The integration of linear motor actuators can lead to reduced maintenance costs, enhanced speed, and improved performance, making them an attractive choice for manufacturers looking to modernize their processes. Understanding the myriad benefits of linear motor actuators not only highlights their importance in contemporary automation but also underscores their potential to revolutionize industrial practices across diverse sectors.

Linear motor actuators have emerged as a pivotal component in precision engineering applications, offering numerous advantages that enhance automation solutions. One of the primary benefits of these actuators is their ability to deliver high-speed and high-accuracy motion control. Unlike traditional rotary motors that require conversion to linear motion, linear motors operate directly, thus minimizing mechanical delays and improving response times. This direct drive mechanism allows engineers to achieve exceptional positional accuracy, which is crucial in fields such as robotics, CNC machining, and semiconductor manufacturing.

Linear motor actuators have emerged as a pivotal component in precision engineering applications, offering numerous advantages that enhance automation solutions. One of the primary benefits of these actuators is their ability to deliver high-speed and high-accuracy motion control. Unlike traditional rotary motors that require conversion to linear motion, linear motors operate directly, thus minimizing mechanical delays and improving response times. This direct drive mechanism allows engineers to achieve exceptional positional accuracy, which is crucial in fields such as robotics, CNC machining, and semiconductor manufacturing.

Another significant advantage of linear motor actuators is their inherent simplicity in design and integration. With fewer moving parts, they not only reduce mechanical wear but also lower maintenance requirements and operational costs. This reliability is essential for precision applications where consistent performance is necessary. Additionally, the compact form factor of linear motor actuators enables engineers to design more flexible and space-efficient systems. The result is a more streamlined automation solution that can be adapted to various industrial challenges without compromising precision, thereby optimizing overall productivity and output quality.

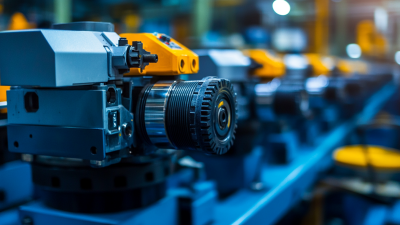

Linear motor actuators have emerged as a transformative technology in modern automation solutions, offering distinct advantages over traditional actuation methods. Unlike conventional systems that rely on mechanisms such as gears or belts, linear motors provide direct drive capabilities, which enable smoother and faster movements. This direct approach reduces mechanical wear and increases reliability, making linear motor actuators an ideal choice for applications requiring high precision and speed. Moreover, their compact design allows for easier integration into existing systems, further enhancing their appeal.

When comparing linear motor actuators to traditional methods, the efficiency gap is noteworthy. Traditional actuators often suffer from energy losses due to friction and inertia in their mechanical components. In contrast, linear motor actuators operate with minimal losses, providing superior energy efficiency. Additionally, they allow for greater motion control and flexibility, accommodating dynamic adjustments in real time. This level of performance not only boosts productivity but also reduces downtime, making linear motor actuators a smart investment for industries seeking to optimize their operations.

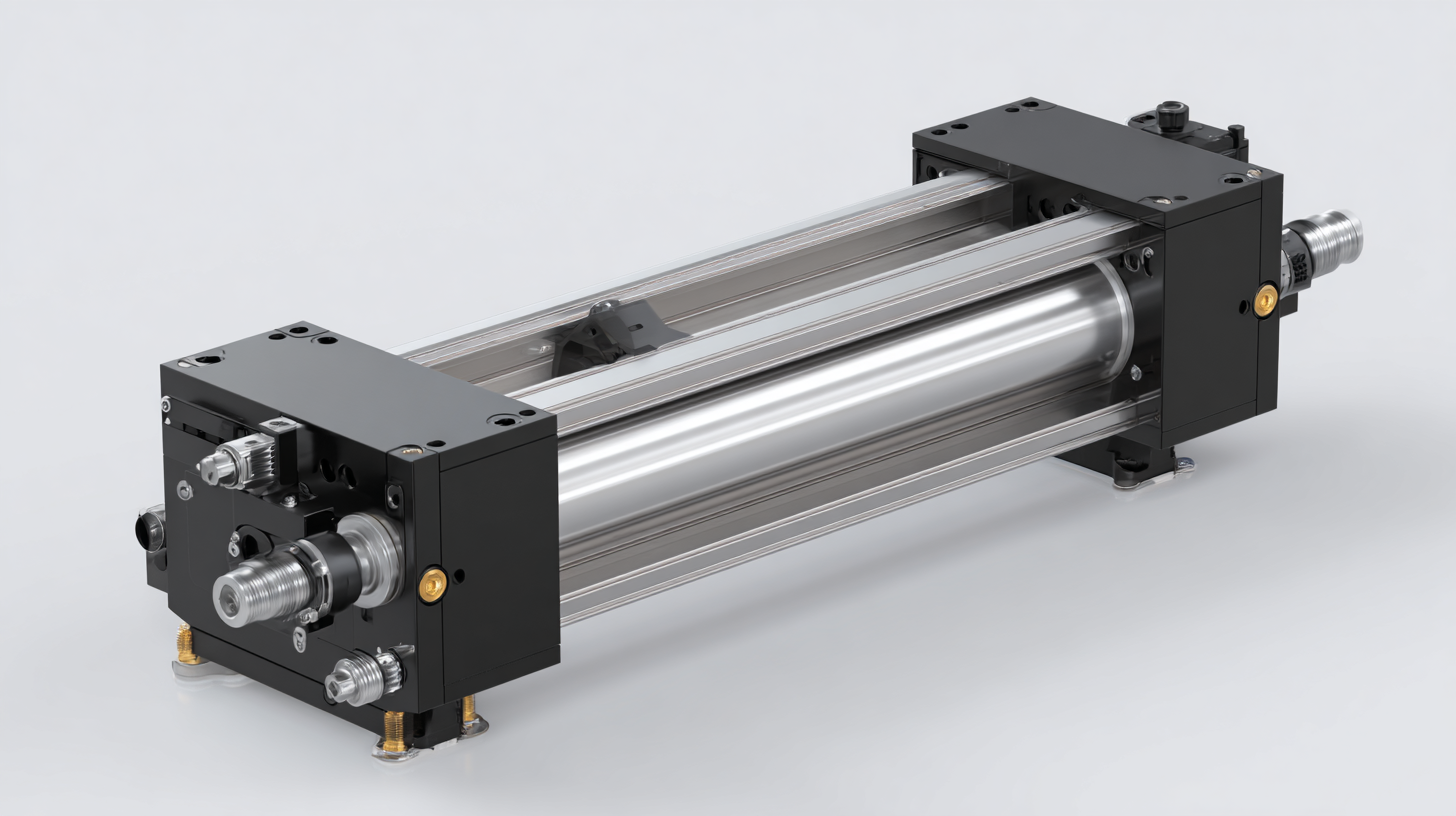

Linear motor actuators have emerged as a vital component in modern automation solutions, primarily due to their impressive performance metrics such as speed, efficiency, and load capacity. These actuators are designed to provide rapid movement, contributing to decreased cycle times in manufacturing processes. With their direct drive systems, linear motors eliminate the need for mechanical linkages, enabling faster response times and the ability to achieve high acceleration rates. This speed translates into increased productivity, particularly in applications where time is critical.

Efficiency is another key benefit of linear motor actuators. Their design minimizes energy losses, making them more environmentally friendly and cost-effective over time. The lack of friction found in traditional drive systems not only enhances longevity but also contributes to lower maintenance requirements. Additionally, linear motors can support varying load capacities, allowing them to adapt to different operational needs without compromising performance. This versatility makes them suitable for a wide range of applications, from precision positioning in robotics to heavy-duty tasks in industrial settings.

| Metric | Value | Unit |

|---|---|---|

| Max Speed | 5 | m/s |

| Efficiency | 90 | % |

| Load Capacity | 250 | kg |

| Response Time | 10 | ms |

| Maintenance Interval | 5000 | hours |

Linear motor actuators are rapidly becoming critical components in modern automation systems, offering numerous advantages, particularly in maintenance cost reduction. According to a report from Research and Markets, the global linear motor market is expected to reach $5.77 billion by 2026, growing at a CAGR of 8.52%. This growth can be attributed to the reliability and efficiency of linear motors, which require less maintenance compared to traditional rotary systems. As linear motors operate without gears or mechanical linkages, the likelihood of wear and tear is significantly decreased, leading to fewer unforeseen breakdowns and minimizing the need for expensive replacements.

Moreover, a study conducted by the International Society of Automation highlights that incorporating linear motor actuators can reduce maintenance costs by up to 30%. This not only helps in lowering operational expenditures but also enhances overall system uptime. As industries become increasingly reliant on automation, the transition to linear motor technology not only streamlines operations but also represents a strategic investment for businesses aiming to optimize maintenance workflows. The upfront investment in these sophisticated actuators pays off through long-term reliability and a decrease in labor costs associated with regular maintenance checks and repairs.

In the landscape of Industry 4.0, linear motor actuators are becoming pivotal in the evolution of robotics and automation technology. Their ability to deliver high speed, precision, and efficiency makes them ideal for a variety of applications, from assembly lines to robotic arms. As factories integrate smart technology, linear motor actuators play a crucial role by facilitating real-time data exchange and adapting to changing operational conditions. This adaptability is essential for maintaining productivity and reducing downtime, which are key metrics in modern manufacturing environments.

Moreover, the convergence of linear motor actuators with advanced robotics heralds a new era of automation. These actuators are not only enhancing the capabilities of robots, allowing them to perform complex tasks with greater accuracy, but also revolutionizing the ways in which robots collaborate with humans. The emerging trends indicate a shift towards more flexible and scalable production systems, where linear motor actuators can be seamlessly integrated into platforms that utilize AI and IoT technologies. This integration is crucial for achieving the ideal manufacturing process, which emphasizes efficiency, customization, and rapid response to market demands.