-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In today's fast-paced industrial landscape, the importance of precision and efficiency cannot be overstated. Linear Servo Motors play a pivotal role in modern applications, enabling unparalleled performance and control. As Dr. Emily Carter, a leading expert in motion control technology, states, “Linear Servo Motors transform conventional design into high-speed, high-precision solutions.”

These advanced motors offer numerous benefits. They can enhance productivity significantly. For instance, they reduce cycle times in automation systems. Moreover, they provide accurate positioning, which is essential in sectors like robotics and manufacturing.

Despite their advantages, some challenges remain. Not all applications may suit Linear Servo Motors. Their initial cost can be higher compared to standard motors. Yet, their long-term benefits often outweigh these considerations. As industries demand higher efficiency, exploring the potential of Linear Servo Motors becomes crucial. There is always room for improvement in integrating this technology.

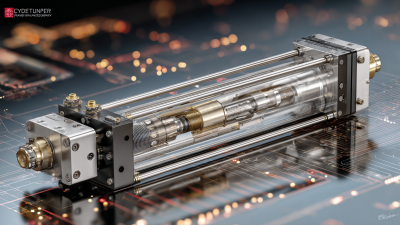

Linear servo motors are revolutionizing precision motion control. They provide unparalleled accuracy and responsiveness. This level of control is essential in fields like manufacturing and robotics. A small change in input can lead to precise movements, ensuring tasks are completed correctly.

One notable advantage is their direct drive capability. Without belts or gears, linear servo motors reduce wear and tear. This enhances system reliability and maintenance. However, some users find initial setup challenging. Understanding how to calibrate these motors can take time and effort. This learning curve is definitely a factor to consider.

Another benefit lies in their compact design. They occupy less space compared to traditional systems. This can be a game-changer, especially in tight environments. But, users should be aware of potential heat generation during extensive use. Monitoring temperature is crucial to avoid issues. Balancing performance with care is essential for long-term success.

Linear servo motors are becoming a go-to choice in modern industrial automation. Their unique design allows for precise control of movement. As a result, these motors enhance efficiency and bring substantial energy savings. According to a report by the International Energy Agency, machinery accounts for 47% of global energy consumption in the industrial sector. The integration of linear servo motors can reduce energy usage by up to 30%.

Beyond energy savings, these motors provide consistent performance. They can achieve acceleration and deceleration in under 100 milliseconds. This speed means production lines can operate at higher rates. An industry study found that systems incorporating linear servo motors see productivity boosts of up to 25%. However, the initial investment in these technologies can be high. Companies must assess if the long-term savings justify the upfront costs.

Moreover, while linear servo motors are efficient, they can require significant maintenance. Properly calibrating and servicing these motors is essential for sustained performance. Ignoring maintenance can lead to inefficiencies and prolonged downtimes, hindering overall productivity. Keeping track of performance metrics can help organizations address these challenges effectively.

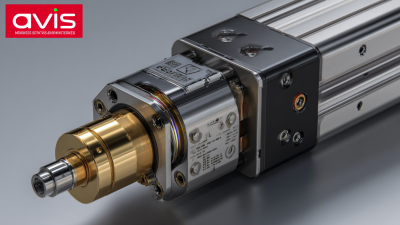

In today's fast-paced industrial landscape, linear servo motors stand out for their remarkable speed and acceleration capabilities. These motors convert electrical energy directly into linear motion, which is crucial for achieving high-performance in machinery. Their design allows for quick responses, making them ideal for applications requiring rapid movements. In sectors like automation and robotics, the speed of operations can significantly impact productivity.

The acceleration of linear servo motors is equally impressive. They can reach peak performance with minimal delays, providing consistent reliability. This benefit is vital for precise tasks such as material handling or assembly lines. While many industries reap the rewards, some may still lag behind in adapting these technologies. The hesitation to transition often stems from a fear of failure—an understandable concern. However, embracing these innovations is essential to staying competitive.

Not all applications might need the extreme speeds and accelerations offered by linear servo motors. Some may find that traditional systems suffice. It's a delicate balance between upgrading to advanced technology and evaluating specific needs. Making the right choice is crucial for optimizing both performance and costs. Exploring this technology can open new avenues, but caution and reflection are necessary. Achieving the best performance involves understanding and acknowledging one’s requirements.

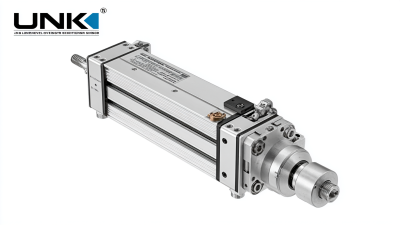

Linear servo motors have become a staple in modern applications due to their precision. One of the most significant benefits is reduced wear and tear. These motors have fewer moving parts compared to traditional motors. This design minimizes friction and leads to longevity.

When wear is minimized, maintenance costs drop significantly. Businesses can save money and improve operational efficiency through these systems. This factor is crucial in industries reliant on heavy machinery. Regular wear can lead to costly repairs and downtimes.

**Tips:** Regularly check the motor for any unusual sounds. Implement a basic inspection schedule. Monitoring helps catch potential issues early. Maintenance does not mean constant repairs. Focus on preventive measures instead. This approach keeps costs low and devices running smoothly. Consider training staff on these principles. Proper knowledge leads to better care and fewer problems.

Linear servo motors are making waves across various industries like robotics and aerospace. Their precision and speed set them apart. In robotics, these motors enhance movement accuracy. Tasks such as robotic arms become more fluid and responsive. Imagine a robotic hand delicately assembling a tiny component. This level of control is crucial in modern manufacturing.

In the aerospace sector, linear servo motors help with critical applications. For example, they can improve the performance of aircraft control surfaces. However, integration isn't always straightforward. Engineers must grapple with weight limitations and space constraints. These challenges can lead to innovative solutions or setbacks during development. The pursuit of perfection in design often leads to unexpected obstacles, requiring constant re-evaluation.

While the benefits are clear, challenges remain. The initial cost and complexity of these systems can deter some applications. Yet, in the long run, their efficiency and accuracy provide compelling returns. As industries continue to innovate, linear servo motors will likely evolve, pushing boundaries in technology and design.