-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

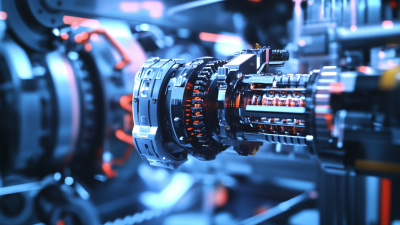

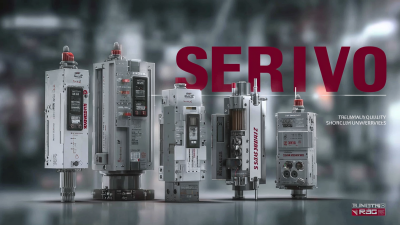

In the rapidly evolving landscape of modern automation systems, the role of Servo Drives has become increasingly pivotal. These sophisticated components not only enhance performance but also contribute to improved efficiency and precision in various applications. By employing closed-loop control systems, Servo Drives enable machines to achieve remarkable accuracy in positioning and speed, leading to significant productivity gains. Their adaptability to different environments and compatibility with a wide range of control architectures make them essential for industries aiming to thrive in a competitive market.

As we explore the numerous advantages that Servo Drives offer—from energy savings and reduced wear on mechanical systems to the ability to integrate seamlessly with advanced technologies like IoT and AI—we gain a deeper appreciation for their transformative impact on automation processes. This comprehensive understanding of Servo Drives is vital for engineers and decision-makers looking to leverage their capabilities in the quest for operational excellence.

As we explore the numerous advantages that Servo Drives offer—from energy savings and reduced wear on mechanical systems to the ability to integrate seamlessly with advanced technologies like IoT and AI—we gain a deeper appreciation for their transformative impact on automation processes. This comprehensive understanding of Servo Drives is vital for engineers and decision-makers looking to leverage their capabilities in the quest for operational excellence.

In modern automation systems, servo drives are paramount for enhancing precision control. These sophisticated devices enable accurate control of angular and linear motions, ensuring that machinery operates with unmatched exactness. The global integrated servo motor market, valued at $5.29 billion in 2023, is poised for significant growth as industries seek advanced solutions to improve efficiency and responsiveness in high-speed processes. Projections indicate this market will reach $8.75 billion by 2035, highlighting the accelerating demand for precise motion control technologies.

Moreover, the evolution of motion control technologies, including servo advancements, is pivotal in shaping the future of automation. The ability of servo drives to provide real-time feedback and dynamic response allows for optimized performance in various applications, from robotics to packaging machinery. As companies strive for increased productivity and reduced downtime, investing in quality servo systems is becoming a strategic priority.

**Tip:** To maximize the benefits of servo drives, ensure proper integration with existing systems and regularly update software for optimal performance.

In addition, businesses can explore single-axis drives, which are also witnessing promising growth in the market, predicted to increase from $273.5 million in 2025 to $480.7 million by 2035 at a CAGR of 5.8%. Implementing these technologies can significantly enhance precision control and overall production efficiency.

**Tip:** Conduct a thorough assessment of your automation needs to identify the most suitable drive options, ensuring alignment with your operational goals.

| Benefit | Description | Impact on Automation |

|---|---|---|

| Precision Control | Servo drives provide highly accurate control over speed, position, and torque. | Improves overall process efficiency and product quality. |

| Energy Efficiency | Servo drives use power only when needed, leading to lower energy consumption. | Reduces operational costs and minimizes environmental impact. |

| Speed and Performance | Capable of rapid acceleration and deceleration, increasing productivity. | Enables faster cycle times and improves throughput. |

| Flexibility | Easily programmable to adapt to varying tasks and production volumes. | Supports agile manufacturing and quick product changes. |

| Enhanced Integration | Seamlessly integrates with modern control systems and other automation components. | Improves system cohesion and data communication. |

Modern servo drive technologies play a pivotal role in enhancing energy efficiency within automation systems. These advanced systems are designed to offer precise control over motors, enabling them to operate at optimal levels based on real-time feedback. This level of control not only improves the responsiveness of machinery but also significantly reduces energy consumption compared to traditional drive systems. By adjusting power usage dynamically, servo drives minimize waste and ensure that energy is used only when necessary, ultimately leading to lower operational costs.

Modern servo drive technologies play a pivotal role in enhancing energy efficiency within automation systems. These advanced systems are designed to offer precise control over motors, enabling them to operate at optimal levels based on real-time feedback. This level of control not only improves the responsiveness of machinery but also significantly reduces energy consumption compared to traditional drive systems. By adjusting power usage dynamically, servo drives minimize waste and ensure that energy is used only when necessary, ultimately leading to lower operational costs.

Furthermore, the integration of servo drives in automation systems allows for smoother acceleration and deceleration profiles, leading to less mechanical stress and reduced wear on components. This not only extends the lifespan of the equipment but also contributes to energy savings by ensuring that motors do not consume excess energy during idle or transitional phases. As industries increasingly prioritize sustainability, the ability of modern servo drive technologies to improve energy efficiency makes them an invaluable asset in the push towards greener and more cost-effective production methods.

The integration of servo drives in robotics has revolutionized modern automation systems, significantly enhancing productivity across various industries. Servo drives provide precise control over motor speed and position, allowing robotic arms and systems to perform complex tasks with remarkable accuracy. This precision is essential in applications such as assembly lines, where even minute errors can lead to significant production losses. By utilizing servo drives, robots can adapt quickly to changing demands, ensuring optimal performance and minimizing downtime.

Moreover, the responsiveness and efficiency of servo drives facilitate smoother operations within automated systems. This capability enables robots to execute tasks more rapidly, thereby increasing overall throughput. In environments such as manufacturing and warehousing, the ability to seamlessly coordinate multiple robotic units through servo technology enhances workflows and reduces operational bottlenecks. As a result, organizations can achieve higher output levels and better resource utilization, all while maintaining high standards of quality and safety in their operations. The impact of integrating servo drives in robotics extends beyond mere productivity enhancements; it fosters a competitive edge in an increasingly automated market.

As industries increasingly focus on optimizing their operational expenses, servo drives have emerged as a key technology. These drives not only enhance precision and control in automation systems but also contribute significantly to cost-effectiveness. The global energy efficient motor market, projected to grow from $54.60 billion in 2025 to $80.86 billion by 2032 at a CAGR of 5.77%, highlights the increasing trend towards energy-efficient solutions. This growth underscores the demand for servo drives, which facilitate energy savings through advanced motor technology and enhanced efficiency.

Micro-sized servo drives are particularly notable for their ability to deliver high performance while minimizing spatial requirements and weight. This innovation opens new avenues for design, enabling manufacturers to create more compact systems without sacrificing performance. An integrated approach to servo motors further enhances this benefit, with the global market expected to rise from $5.29 billion in 2023 to substantially higher figures by 2032.

Tip: When considering servo drives, evaluate the potential energy savings in relation to your operational costs. Innovations like energy recovery systems can significantly enhance your facility's sustainability and efficiency. Tip: Investigate strategic partnerships within your supply chain, as collaborations can drive advancements in technology and improve overall system performance.

Servo drives play a pivotal role in the advancement of Industry 4.0 technologies by providing precision and control that are essential for smart manufacturing. These drives facilitate enhanced automation systems that interact seamlessly with IoT devices, allowing for real-time data analysis and improved decision-making processes. By integrating servo drives, manufacturers can optimize their production lines, achieve higher efficiency, and reduce downtime, thus meeting the growing demands of the digital age.

**Tip:** When implementing servo drives, consider conducting a thorough analysis of your current systems to identify areas where precision control can yield the most significant improvements. This helps in aligning your investments with your production goals.

Moreover, the ability of servo drives to adapt to various applications— from robotics to CNC machines— makes them invaluable in Industry 4.0 environments. Their feedback mechanisms ensure accurate positioning and speed control, which are vital for advanced automation tasks. As industries seek to enhance their operational capabilities, the adoption of servo drives becomes a strategic necessity.

**Tip:** Regular training for your workforce on new servo technology can greatly enhance the effectiveness of these systems, ensuring that all team members are equipped to maximize their potential.