-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

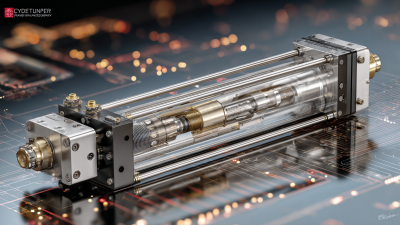

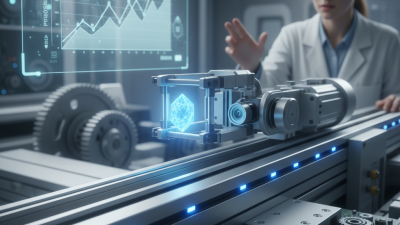

Linear motor actuators have gained popularity in various industries. They offer precision and speed that traditional actuators often cannot match. Designed for simplicity, these devices directly convert electrical energy into linear motion. This results in reduced mechanical wear and a longer lifespan.

One key benefit of using a linear motor actuator is its quick response time. This makes it ideal for applications requiring fast positioning. Their ability to maintain accuracy over extended periods is impressive. However, there are challenges. For instance, installation can be complex and requires careful alignment.

Noise levels can also be a concern for some users. While linear motor actuators are generally quieter than traditional systems, they are not completely silent. Additionally, cost is another factor to consider. High-performance models can be expensive. Understanding these pros and cons helps users make informed decisions.

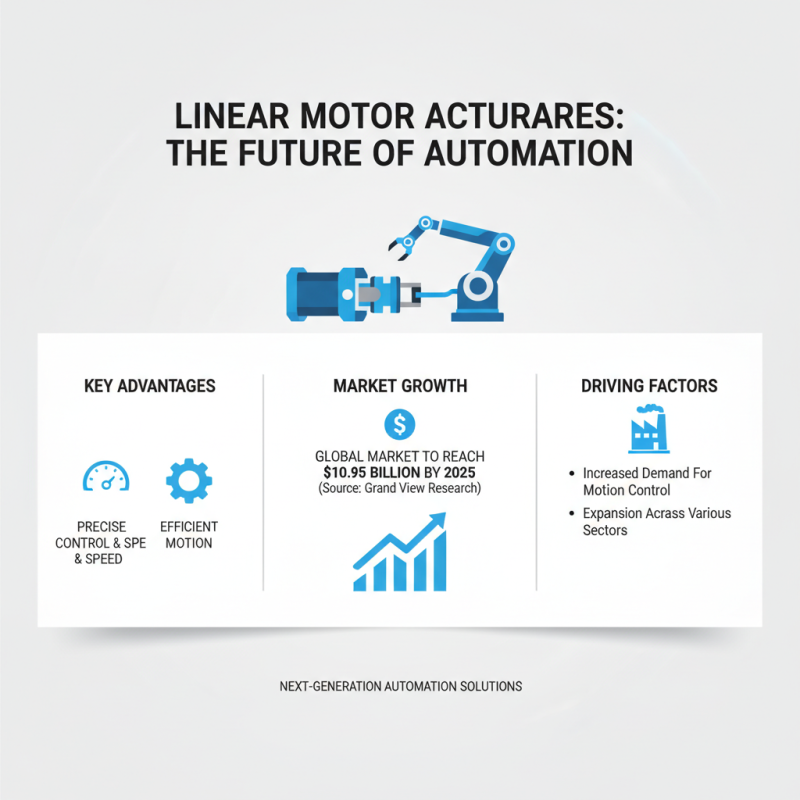

Linear motor actuators are gaining traction in automation applications. Their precise control and speed offer distinct advantages. According to a report by Grand View Research, the global linear motor market is projected to reach $10.95 billion by 2025. This growth is driven by a surge in demand for motion control systems across various sectors.

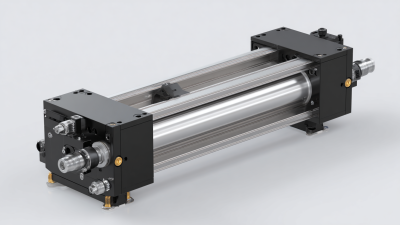

One major benefit is their high acceleration capabilities. They can achieve acceleration rates exceeding 50 m/s². This performance enhances productivity and reduces cycle times in manufacturing. Moreover, they are easier to maintain compared to traditional systems. With fewer moving parts, linear motor actuators tend to have lower failure rates. However, their upfront costs might be a concern for small businesses.

Tips: Consider system compatibility when integrating linear motor actuators. Assess the application requirements and potential ROI. Investing in well-researched automation solutions can lead to improved efficiency. Evaluate the trade-offs between costs and benefits carefully. Remember, not every application requires cutting-edge technology. Sometimes, simpler solutions can still yield significant performance gains.

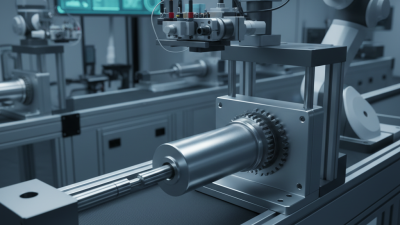

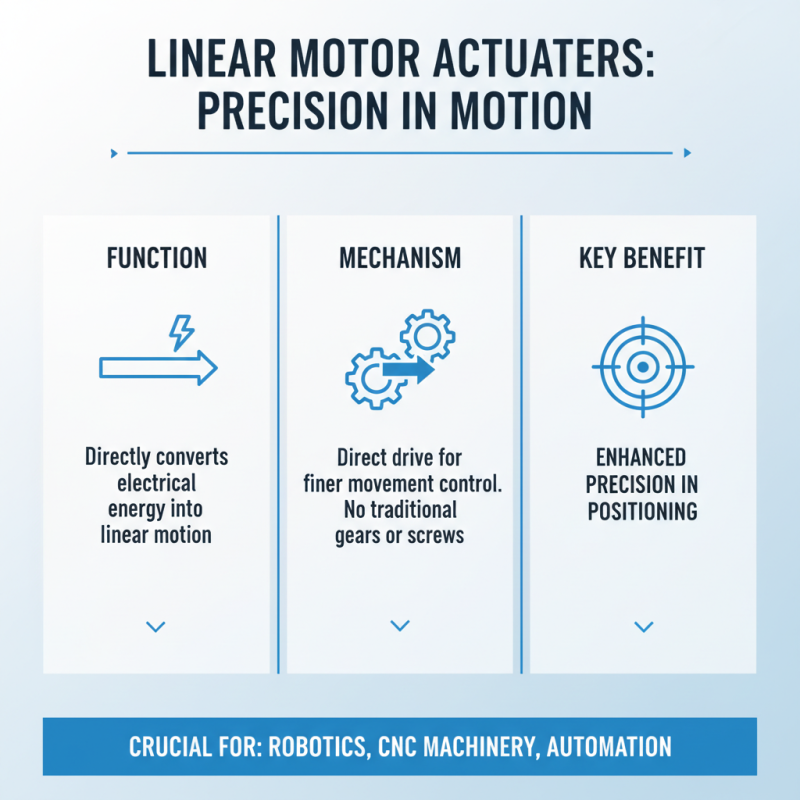

Linear motor actuators have emerged as pivotal tools in industries that prioritize precision. They convert electrical energy into linear motion directly. This direct drive mechanism allows for finer control over movements. As a result, the precision in positioning is significantly enhanced. This can be crucial in applications like robotics or CNC machinery.

In the quest for accuracy, linear motors shine. Traditional methods often introduce delays and errors due to mechanical components. However, linear actuators reduce these inconsistencies. They achieve rapid responses to control signals. This capability facilitates quick adjustments, enabling more accurate task execution. The immediate feedback loops mean operators can trust the data they receive. Yet, the complexity of integrating these systems can sometimes lead to miscalculations in setup.

Despite their advantages, challenges exist. Calibration is essential for maintaining precision. Without it, discrepancies may arise. Observing and analyzing performance over time can help identify these flaws. Regular maintenance becomes crucial to ensure consistent operation. This commitment to detail is key when relying on the enhanced precision these motors provide.

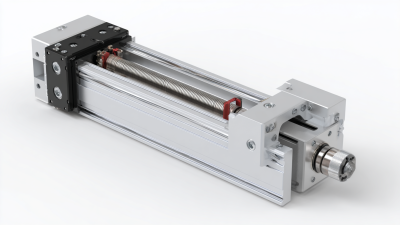

Linear motor actuators are gaining popularity due to their remarkable speed and responsiveness. Unlike traditional actuators, they don't rely on gears or belts. This design allows for faster movement, making them ideal for applications requiring quick and precise motions. With direct drive capabilities, the components experience less wear and tear. This translates to longer lifespans and reduced maintenance costs.

In many situations, speed is crucial. For robotic systems, a faster response can mean enhanced performance. Linear motors can move at high velocities, improving productivity in industrial settings. They can adapt rapidly to changing conditions. This adaptability is a significant advantage over conventional actuators, which may lag behind in response. However, users must consider that the benefits can come at a higher initial cost. It's essential to weigh these factors carefully before making a decision.

| Benefit | Linear Motor Actuators | Traditional Actuators |

|---|---|---|

| Speed | Up to 10 times faster | Slower response time |

| Responsiveness | Immediate motion change | Lag in response |

| Accuracy | High precision | Moderate accuracy |

| Maintenance | Low maintenance | Regular maintenance required |

| Energy Efficiency | More efficient | Less efficient |

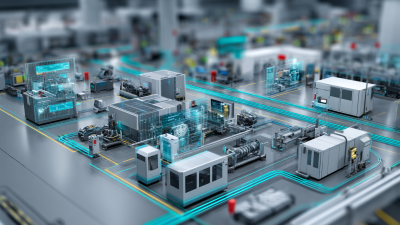

Linear motor actuators are revolutionizing the way industries approach automation. One significant advantage is their lower maintenance requirements. Traditional actuators often rely on gears and heavy mechanics, which can wear out quickly. In contrast, linear motors have fewer moving parts. According to a recent industry report, they can reduce maintenance needs by up to 40%. This means less downtime for businesses.

Furthermore, using linear motor actuators leads to reduced operational costs. These actuators improve energy efficiency, consuming 30% less power than conventional systems. This efficiency translates to significant savings over time. Many industries report lower operating expenses, allowing funds to be reallocated to other crucial areas. However, there’s a catch. The initial investment can be higher. Companies may hesitate due to upfront costs, even with long-term savings in sight.

Despite these challenges, many manufacturers are choosing linear motors for their production lines. They acknowledge that while the shift might be costly at first, the return on investment can be substantial. It pushes businesses to innovate and adapt. Thus, the debate continues: is the initial cost worth the long-term benefits? This question lingers as technology advances and industries evolve.

Linear motor actuators are gaining traction in various industries. Their unique design offers precision and speed, making them ideal for diverse applications. In automotive manufacturing, for instance, they streamline assembly lines. According to a recent report by ResearchAndMarkets, the linear actuator market is projected to grow at a CAGR of 8.5% from 2021 to 2026.

In the robotics sector, linear motor actuators play a vital role. They enhance efficiency and accuracy in repetitive tasks. Industries like healthcare are also adopting them in surgical robots. This adoption reflects a shift towards automation for better patient outcomes. However, balancing speed and control remains a challenge in some applications.

Tip: When choosing a linear motor actuator, consider the specific needs of your application. Look for compatibility with your existing systems.

The technology is versatile, from aerospace to packaging. However, manufacturers must ensure the durability of these actuators. Real-world feedback indicates potential wear issues in high-stress environments. This calls for ongoing evaluation and optimization of actuator design. Companies should be prepared for continuous improvement to maximize the benefits.