-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the realm of modern automation systems, the integration of advanced technologies has become paramount for enhancing efficiency and productivity. Among these innovations, the Servo Drive stands out as a transformative solution that plays a critical role in controlling motion and providing precise operation across various applications. As industries continuously strive for optimization, understanding the benefits of Servo Drives is essential for engineers and decision-makers seeking to stay ahead in an increasingly competitive landscape.

The Servo Drive system offers a remarkable combination of accuracy, reliability, and responsiveness, making it indispensable for tasks that require high levels of control. From robotics to manufacturing processes, the precision that Servo Drives bring to automated systems allows for improved performance, minimized downtime, and reduced operational costs. As we delve into the top ten benefits of using Servo Drives, it becomes clear how this technology not only streamlines operations but also enhances overall system capabilities, empowering businesses to meet evolving demands with confidence and agility.

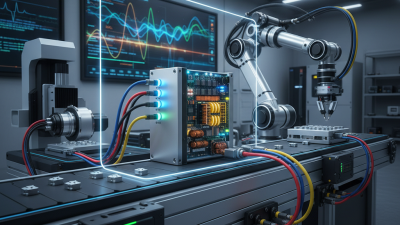

Servo drives are integral components in modern automation systems, providing precise control over motion and positioning. By converting electrical energy into mechanical motion, they facilitate the seamless operation of machinery in various industrial applications. Understanding the mechanics of servo drives involves recognizing their ability to provide feedback, which allows for real-time adjustments and improvements in accuracy. This feedback loop ensures that systems can respond dynamically to changing conditions, enhancing efficiency and productivity.

In automation, servo drives play a crucial role in maintaining consistency and reliability. Their advanced control algorithms enable smooth and precise adjustments to speed, torque, and position, making them ideal for tasks ranging from robotic arms to conveyor systems. The integration of servo drives allows manufacturers to automate complex processes, reduce operational costs, and improve overall system performance. As industries continue to advance towards smart automation solutions, the importance of understanding and implementing servo drives will only grow, positioning them as a cornerstone of future technological innovations in automation.

In modern automation systems, servo drives play a crucial role in enhancing precision control applications across various industries. One of the key advantages of servo drives is their ability to deliver high accuracy and responsiveness, which is essential for tasks requiring fine movement and positioning. Unlike traditional systems, servo drives utilize feedback mechanisms that continuously monitor the position and speed of the actuator, allowing for real-time adjustments. This results in improved performance for applications such as robotic arms, CNC machines, and automated assembly lines, where even minor deviations can lead to significant errors.

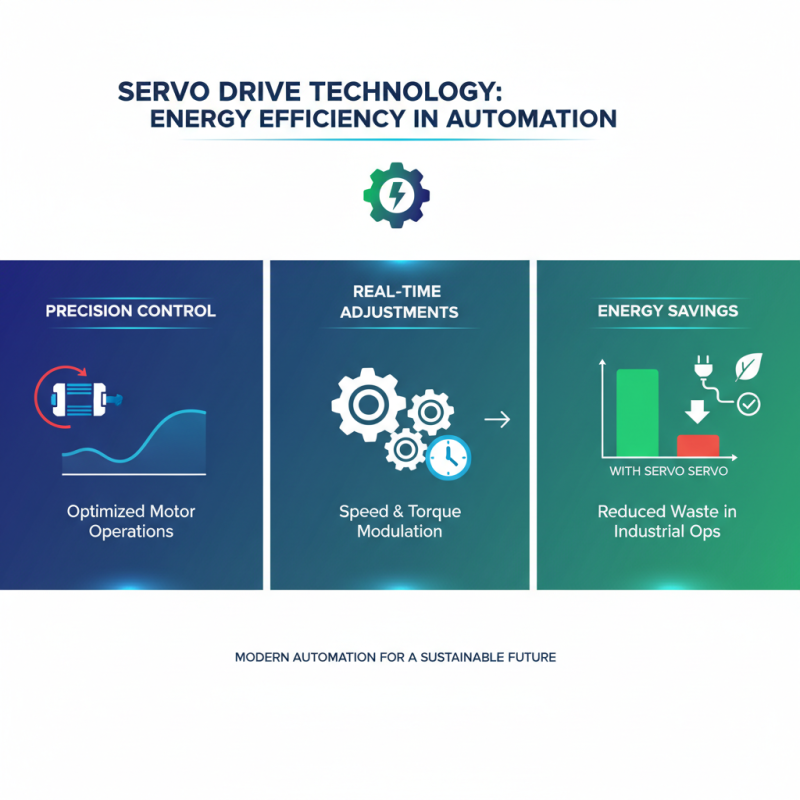

Another significant benefit of servo drives is their energy efficiency. By efficiently controlling the motor's power consumption based on load requirements, servo drives minimize unnecessary energy usage. This not only reduces operational costs but also contributes to a lower environmental impact. Furthermore, the ability to program servo drives for various duties allows manufacturers to optimize their systems for different applications, enhancing productivity while maintaining exceptional precision and reliability.

As industries continue to evolve, the adoption of servo drives is becoming increasingly vital for achieving superior control and efficiency in automation processes.

The integration of servo drive technology in modern automation systems brings significant benefits, particularly in enhancing energy efficiency. Servo drives are designed to provide precise control over motor operations, allowing for optimized energy consumption. By adjusting motor speed and torque in real-time according to the demands of the application, these systems minimize energy waste, which is especially critical in large-scale industrial operations.

Moreover, the superior responsiveness of servo drives allows for faster and more precise movements, leading to reduced cycle times and less energy required per operation. Traditional systems, which may operate at fixed speeds and load levels, often lead to overuse of energy even during idling periods. In contrast, servo drive technology enables intelligent load tracking, where energy exertion matches the actual requirements of the system. This adaptive capability not only leads to significant savings on energy bills but also contributes to a reduced carbon footprint, aligning industrial operations with sustainability goals.

Overall, the efficiency gains achieved with servo drive systems underscore their importance in modern automation, proving that they are not just a technological upgrade but a necessary evolution towards more responsible energy consumption.

The integration of servo drives in modern automation systems has significantly enhanced both system performance and reliability. Servo drives offer precision control, allowing for superior speed and position accuracy compared to traditional systems. According to a report from MarketsandMarkets, the global servo drive market is expected to grow from USD 10 billion in 2020 to over USD 14 billion by 2025, underscoring the increasing adoption of these technologies across various sectors. The decrease in cycle time, coupled with improved energy efficiency, indicates that companies are not only achieving better performance but also reducing operational costs, a dual benefit that is hard to overlook.

Moreover, the reliability of servo drives contributes to lower maintenance costs and downtime. With advanced feedback control mechanisms, they can quickly adjust to changing load conditions, minimizing wear and tear on components. A study published by the International Journal of Advanced Manufacturing Technology indicates that implementing servo drive systems can lead to up to 30% reduction in failure rates compared to conventional drives. This reliability enhances the overall productivity of manufacturing processes, ensuring that systems operate with minimal interruptions, thus solidifying the role of servo drives as a cornerstone of modern automation.

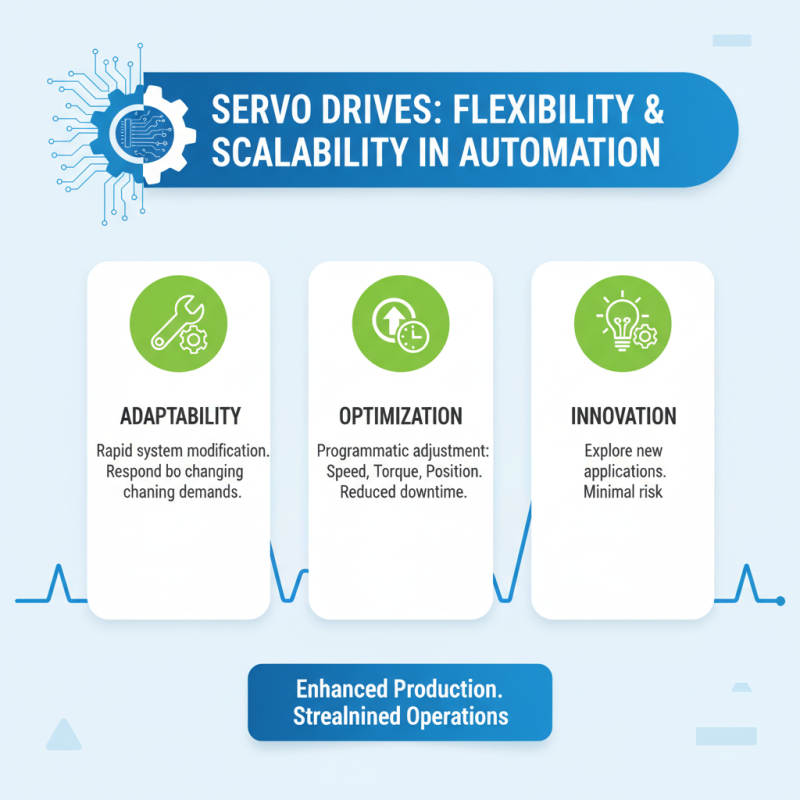

In the realm of modern automation systems, servo drives have emerged as pivotal components that enhance both flexibility and scalability. The inherent adaptability of servo drives allows manufacturers to modify their systems rapidly in response to changing production demands. This capability is particularly beneficial in industries where products and processes evolve frequently. By integrating servo drives, companies can programmatically adjust parameters such as speed, torque, and position, enabling them to optimize the performance of their machinery without extensive downtime or resource investment. This agility not only streamlines operations but also fosters innovation as businesses can explore new applications and production methods with minimal risk.

Furthermore, the scalability provided by servo drives positions businesses favorably in dynamic markets. As production needs grow, these drive systems can be incrementally enhanced to support additional axes of motion or more complex control strategies, without the necessity for a complete overhaul of existing infrastructure. This gradual scalability promotes cost efficiency, allowing organizations to allocate resources more strategically while minimizing the impact on operations. Overall, the combination of flexibility and scalability within servo drive technology empowers manufacturers to maintain a competitive edge, adapt to evolving demands, and invest in future growth.