-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the dynamic world of automation, the importance of choosing the right Servo Drive cannot be overstated. Experts agree that this decision can significantly impact performance. According to Dr. Emily Chen, a leading authority in motion control, “Selecting the best Servo Drive is crucial for maximizing efficiency and precision in applications.”

High-performance applications demand reliable Servo Drives that can handle increased loads and offer precise control. The market in 2026 is evolving, presenting a range of new options tailored for specific needs. Manufacturers are pushing boundaries, yet, the myriad features can sometimes be overwhelming. Some Servo Drives may promise exceptional performance, but real-world tests may reveal their limitations.

Identifying the best Servo Drive for your project should involve careful consideration. It’s not just about the specs; it’s about how these drives perform under pressure. Understanding the nuances of various models can lead to both successes and failures. Balancing innovation with practicality will be the key to future developments in this critical industry.

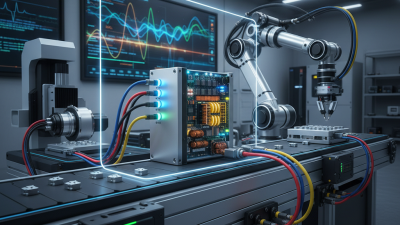

Servo drives are essential components in high-performance applications. They control the power delivered to the motor, ensuring precise movement and speed. This control is critical in robotics, CNC machinery, and automation. When a servo drive operates flawlessly, the entire system benefits. However, poor integration can lead to unexpected errors.

Precision is key. A well-tuned servo drive can enhance responsiveness and efficiency. On the other hand, mismatches in specifications can result in sluggish performance. High-quality feedback mechanisms improve accuracy but may add complexity. Users might struggle to find the right balance. Over time, one may realize that budget constraints often overshadow performance needs. This can lead to regrettable choices that affect long-term outcomes.

In high-performance environments, the responsibility lies with engineers and operators. Continuous monitoring is crucial for optimal function. Yet, many overlook regular diagnostics until an issue arises. Developing a robust maintenance routine may seem cumbersome. However, it ultimately pays off in sustained productivity and performance. Each component matters, from the servo drive to the motor and beyond.

| Drive Type | Voltage Range (V) | Current Rating (A) | Control Type | Feedback Type | Key Features |

|---|---|---|---|---|---|

| Digital Servo Drive | 24 - 480 | 2 - 20 | Position Control | Incremental Encoder | High Efficiency, Compact Design |

| AC Servo Drive | 180 - 400 | 5 - 30 | Torque Control | Absolute Encoder | Smooth Operation, High Load Capacity |

| Servo Drive with EtherCAT | 48 - 600 | 10 - 50 | Velocity Control | Synchronous Encoder | Real-Time Performance, Networked Control |

| Compact Servo Drive | 24 - 60 | 2 - 15 | Position & Torque Control | Resolver | Space-Saving, Simple Integration |

| Open-Loop Servo Drive | 100 - 240 | 1 - 10 | Open-Loop Control | None | Cost-Effective, Easy to Use |

When selecting servo drives for high-performance applications, several key features are essential. Close-loop control ensures precise position and speed. This feature helps maintain accuracy during rapid movements. Another vital aspect is the communication protocol. A flexible protocol allows for easy integration with existing systems. The ability to operate in various environments is also crucial. High-quality materials can enhance durability and performance under challenging conditions.

Tip: Always consider thermal management. Efficient heat dissipation prevents overheating. This extends the lifespan of the servo drive and maintains performance. Check the cooling options provided.

Additionally, the response time is a critical metric to evaluate. Quick response ensures your systems operate seamlessly. Delays can cause inefficiencies. Evaluate the feedback mechanisms, as they play a role in achieving high precision. Make sure to test the drives in real scenarios. This helps identify any weaknesses early.

Tip: Don’t underestimate user interfaces. An intuitive interface makes setup and troubleshooting easier. Investing in user-friendly drives can save time in the long run. Focus on features that enhance overall system performance and reliability.

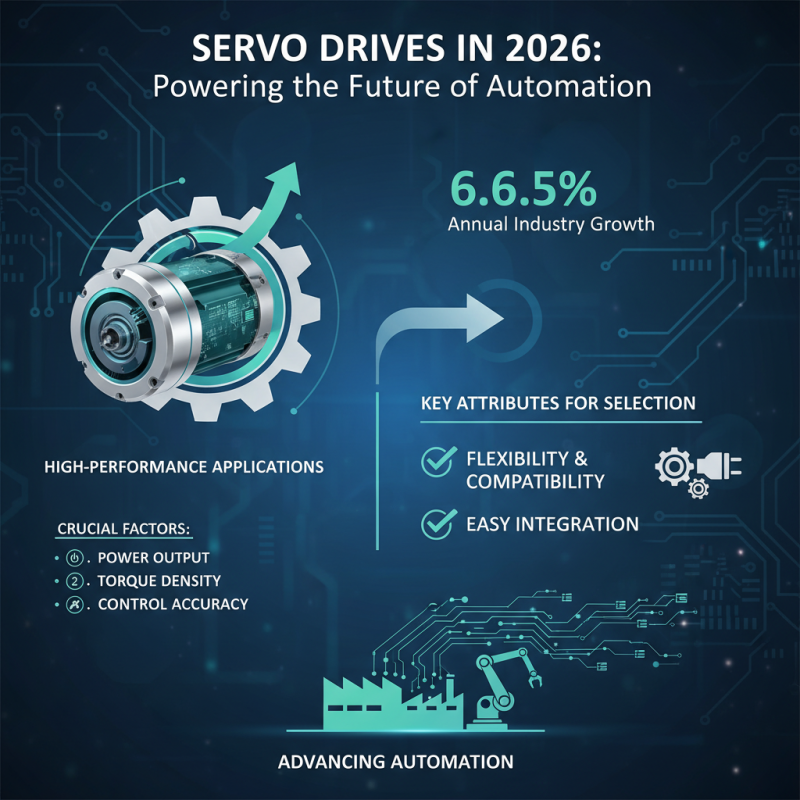

In 2026, servo drives play a vital role in high-performance applications across industries. With an industry growth rate of 6.5% annually, choosing the right servo drive is crucial. Factors like power output, torque density, and control accuracy are essential for performance. As automation advances, companies seek drives that offer flexibility. They require compatibility with various protocols and easy integration.

Data from recent market reports indicate that demand for compact drives is rising. Manufacturers are shifting towards smaller, more efficient units. In fact, over 50% of users prefer drives that maximize energy efficiency while optimizing space. However, some brands lack transparency in performance metrics. This inconsistency can complicate decision-making for engineers seeking precise control systems. Performance comparisons should be based on real-world tests, not just specifications.

User feedback highlights the importance of comprehensive support. Technical challenges often arise, and timely assistance can make a difference. Drive users note that certain brands are more responsive than others in crisis situations. With a growing array of options, it's essential to evaluate each product. Engage with industry forums for insights. Make informed choices based on collective experiences rather than marketing hype.

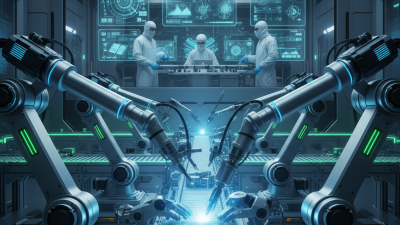

Servo drives play a crucial role across various industries. They are vital in machinery automation, robotics, and manufacturing processes. Applications range from precision control in CNC machines to the smooth operation of conveyor systems. In automotive assembly lines, servo drives ensure accuracy and efficiency. They help in reducing cycle times and increasing productivity.

In the packaging industry, servo drives enhance speed and reliability. They manage packaging machines that require quick adjustments for different products. However, integrating these systems can be challenging. Engineers often face issues like compatibility with older equipment. This creates a need for thorough analysis before implementing new technologies.

In the aerospace sector, precision is non-negotiable. Servo drives contribute to the precise movement of test rigs and simulation systems. Yet, the complexity of these systems can lead to unexpected hiccups. Monitoring and calibrating is essential but can be time-consuming. Many manufacturers find this to be a significant hurdle.

The future of servo drive technology is fascinating. Enhanced performance is a priority in various high-performance applications. Intelligent algorithms will increasingly optimize operational efficiency. These advancements could lead to remarkable improvements in energy consumption and response times. High flexibility in control methods will be pivotal. Imagine a system that adapts dynamically to changing loads. This could minimize downtime and improve overall productivity.

Integration with artificial intelligence is also on the horizon. AI can analyze vast amounts of operational data, predicting potential failures. This allows for proactive maintenance, reducing costly interruptions. However, there may be challenges. Implementing AI requires significant investment and careful planning. Not all systems may be compatible with these new techniques. Ensuring data security is another concern.

Another trend is the use of advanced materials in servo drives. Lightweight, resilient materials could enhance performance and reduce wear. This is crucial for systems where speed and durability are key. While these innovations are promising, they also require deep reflection. Balancing technological advancement with practical application may not always be straightforward.