-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In recent years, the global landscape of manufacturing excellence has prominently spotlighted the significance of Servo Drives, heralding a new era of precision and efficiency in automation technology. According to a report by Fortune Business Insights, the servo drives market is poised to reach USD 11.72 billion by 2028, exhibiting a remarkable compound annual growth rate (CAGR) of 6.9% from 2021 to 2028. As industries increasingly rely on advanced motion control systems to enhance productivity and reduce operational costs, Chinese manufacturers have emerged as key players, leveraging superior engineering capabilities and innovative technologies to lead this sector. This blog will explore how China’s commitment to quality and performance in servo drive manufacturing not only sets industry standards but also positions the nation as a formidable force in the global market.

In the competitive landscape of servo drive manufacturing, after-sales service is a crucial differentiator for Chinese companies. A robust after-sales service structure not only enhances customer satisfaction but also fosters long-term relationships with clients. This commitment to service ensures that users can effectively troubleshoot issues and optimize their equipment's performance, leading to increased operational efficiency.

**Tip:** Always inquire about the after-sales support offered by your supplier. A reliable manufacturer should provide training, access to spare parts, and technical assistance to help you maximize your servo drive's capabilities.

Chinese manufacturers excel in providing comprehensive after-sales service, often incorporating features like remote monitoring and diagnostics. This proactive approach allows businesses to address potential issues before they escalate, reducing downtime and maintenance costs. By focusing on customer needs, these companies demonstrate their dedication to quality and reliability.

**Tip:** Consider the availability of local support when choosing a servo drive manufacturer. Proximity can significantly reduce response time for any necessary repairs or adjustments, ensuring your production line remains uninterrupted.

This chart illustrates the advantages of after-sales service in the Chinese servo drive manufacturing industry over the past few years.

In the realm of industrial automation, the importance of high-quality servo drives cannot be overstated. Research indicates that quality assurance can lead to significant reductions in maintenance costs, which typically account for 15-40% of the total operational expenses in manufacturing facilities. By focusing on quality, companies can not only enhance the reliability of their servo systems but also minimize unexpected downtimes. A report by IndustryWeek highlights that organizations investing in quality assurance programs have experienced an average of 20% reduction in maintenance costs over three years, showcasing the tangible financial benefits of this approach.

Chinese manufacturers are at the forefront of this movement, particularly in producing advanced servo drives with exceptional durability and performance. According to a recent study by MarketsandMarkets, the global servo drive market is expected to grow from $12.38 billion in 2020 to $20.20 billion by 2026, driven largely by advances in manufacturing quality. The commitment to stringent quality control measures has positioned Chinese manufacturers as leaders in delivering reliable servo solutions that not only meet but exceed international standards. This shift not only enhances competitive advantage but also solidifies China's reputation as a key player in the global manufacturing landscape.

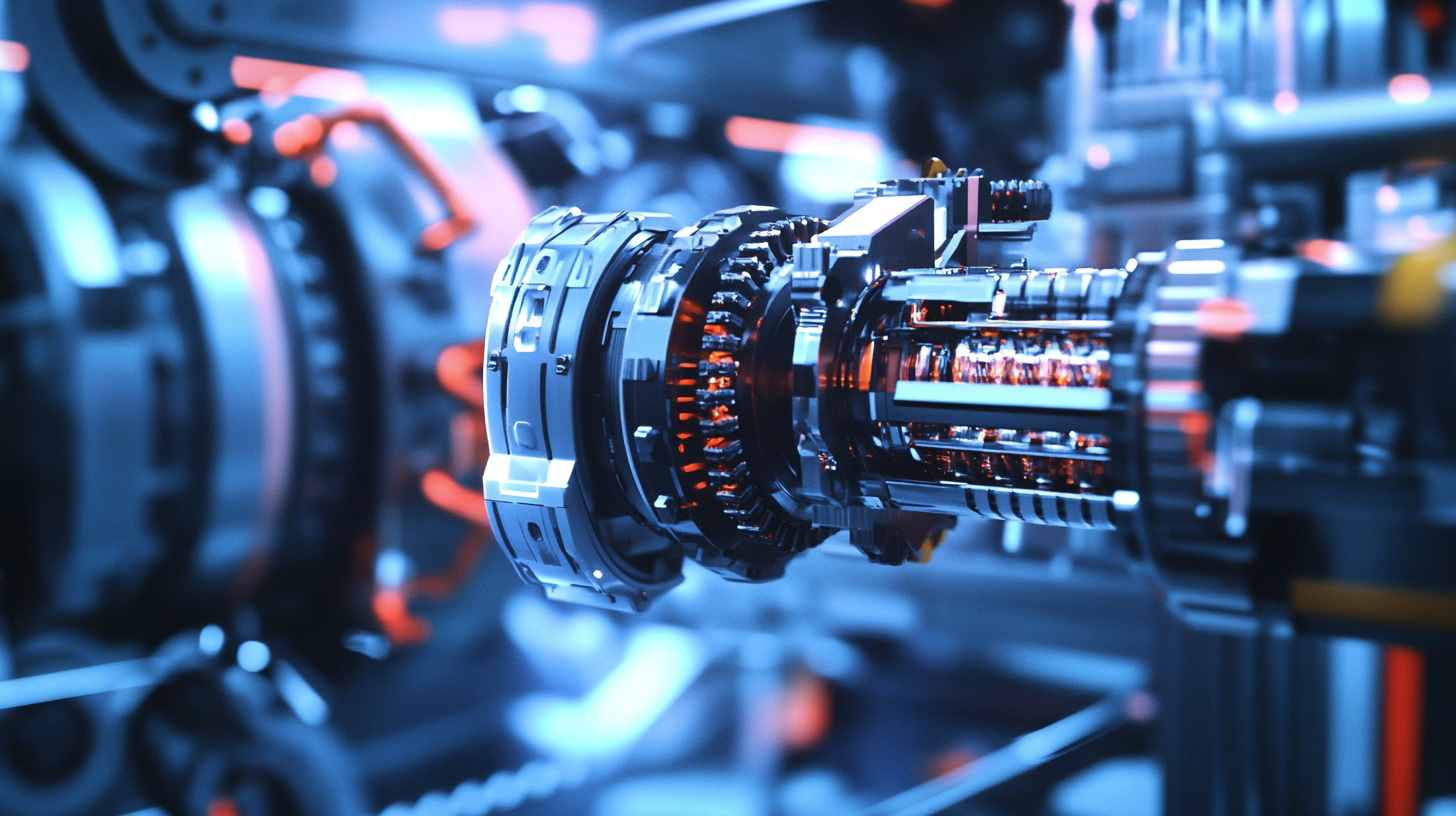

The servo drive technology landscape is evolving rapidly, driven by advancements in automation and precision engineering. According to a recent report by MarketsandMarkets, the global servo drive market is projected to reach $14.5 billion by 2025, growing at a CAGR of 5.1% from 2020. This growth is fueled by increasing demand for high-performance manufacturing systems and the integration of Industry 4.0 technologies, which necessitate more sophisticated drive systems that can enhance efficiency and productivity.

In addition, the shift towards electric and hybrid vehicles is predicted to significantly impact servo drive trends. A study by ResearchAndMarkets indicates that the automotive sector will account for over 35% of the total demand for servo drives by 2026. This change is not just limited to increased production capacity; it is also focused on developing smarter drives that utilize AI and IoT technologies, enabling predictive maintenance and enhanced performance analytics. As Chinese manufacturers continue to lead the way in servo drive innovations, their advancements are likely to set benchmarks that resonate globally, influencing production processes and technological standards across various industries.

| Dimension | Current Value | Projected Growth (2024-2028) | Global Market Impact (2023) |

|---|---|---|---|

| Market Size (USD Billion) | 15.2 | 22.5% | $5 Billion |

| R&D Investment (USD Million) | 750 | 30% | $200 Million |

| Annual Production Capacity (Units) | 1.2 Million | 15% | $4 Billion |

| Percentage of Smart Drives | 35% | 50% | $1.5 Billion |

| Key Export Markets | North America, Europe | - | - |

In today's competitive landscape, customer satisfaction is paramount, particularly in the manufacturing sector. According to a recent study by MarketsandMarkets, the global market for servo drives is expected to reach $13.6 billion by 2025, growing at a CAGR of 6.8%. As Chinese manufacturing seeks to lead in this domain, implementing localized service solutions becomes essential. Tailoring services to meet specific regional needs not only enhances performance but also significantly boosts customer trust and loyalty.

Localized service solutions allow manufacturers to respond swiftly to customer inquiries and technical challenges, reducing downtime and optimizing operational efficiency. For instance, a report by Research and Markets highlights that 65% of customers are more likely to remain loyal to a brand that offers personalized service. By establishing regional support centers and training local technicians, Chinese manufacturers can ensure that they address unique market demands while maintaining the high standards associated with their servo drives. This strategic shift not only enhances product performance but also positions Chinese manufacturing as a leader in customer-centric solutions.

China's ascent as a leader in innovative servo drive engineering is underscored by robust industry data and technological advancements. According to a 2022 report by MarketsandMarkets, the global servo motors and drives market is projected to reach $18.3 billion by 2026, growing at a CAGR of 6.8%. With a significant share attributed to Chinese manufacturers, it is evident that the country is at the forefront of this transformation, leveraging its manufacturing capabilities and expertise in automation.

Chinese companies are investing heavily in research and development, focusing on smart manufacturing solutions that are integral to the evolving landscape of servo drive technologies. The International Federation of Robotics reported that China's robotics market is expected to achieve a value of $65.5 billion by 2025, highlighting the role of servo drives in automation. With their application extending from industrial automation to consumer electronics, China's innovative servo drive engineering not only enhances efficiency and precision but also prompts a paradigm shift in global manufacturing standards.