-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

Stepper motors play a critical role in industrial automation, offering precise control and reliable performance in a variety of applications. According to a recent report by MarketsandMarkets, the global stepper motor market is projected to reach USD 6.56 billion by 2025, growing at a CAGR of 5.4% during the forecast period. This growth is driven by the increasing demand for automation in various industries, including manufacturing, robotics, and aerospace. Stepper motors provide advantages such as high torque at low speeds and the ability to maintain steady motion, making them ideal for tasks requiring accurate positioning and repeatability. As industries continue to evolve toward smarter and more efficient systems, understanding how to choose the best stepper motors for specific applications becomes paramount for optimizing operational performance and achieving competitive advantage.

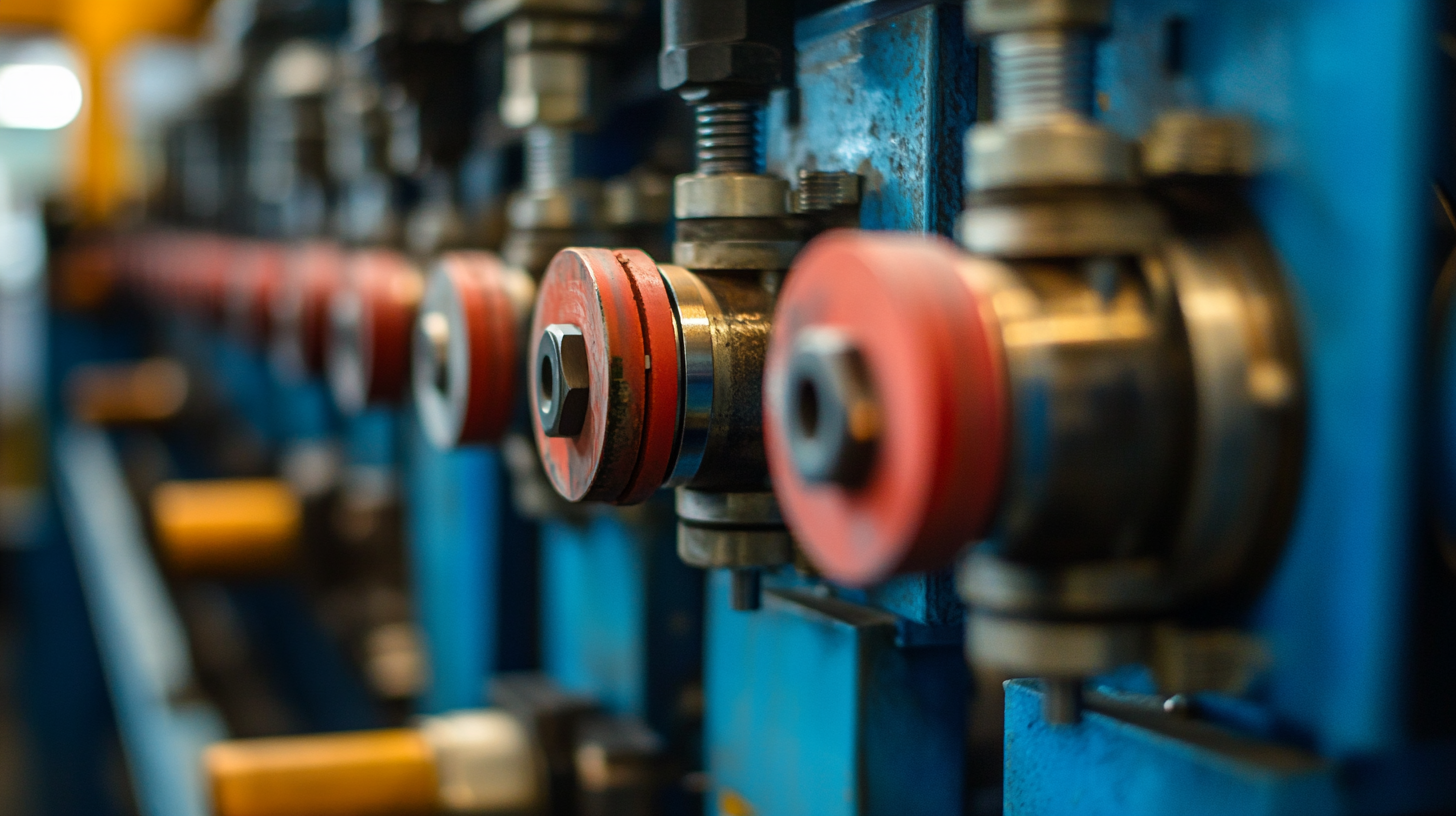

Stepper motors are integral to many industrial applications due to their ability to provide precise control over movement. Understanding the basics of how these motors operate is crucial for selecting the right type for specific tasks. Unlike traditional DC motors, stepper motors rotate in fixed increments, or "steps," allowing for accurate positioning without the need for feedback systems. This makes them ideal for applications that require precise movement, such as CNC machines and 3D printers.

In industrial settings, the choice of stepper motor goes beyond just the number of steps. Factors such as torque, speed, and holding power play significant roles in the motor's effectiveness for a given application. Additionally, the environment in which the motor operates must be considered—temperature fluctuations, dust, and humidity can all affect performance. Understanding these elements ensures that the selected stepper motor not only meets the technical requirements but also provides reliability and longevity in demanding industrial conditions.

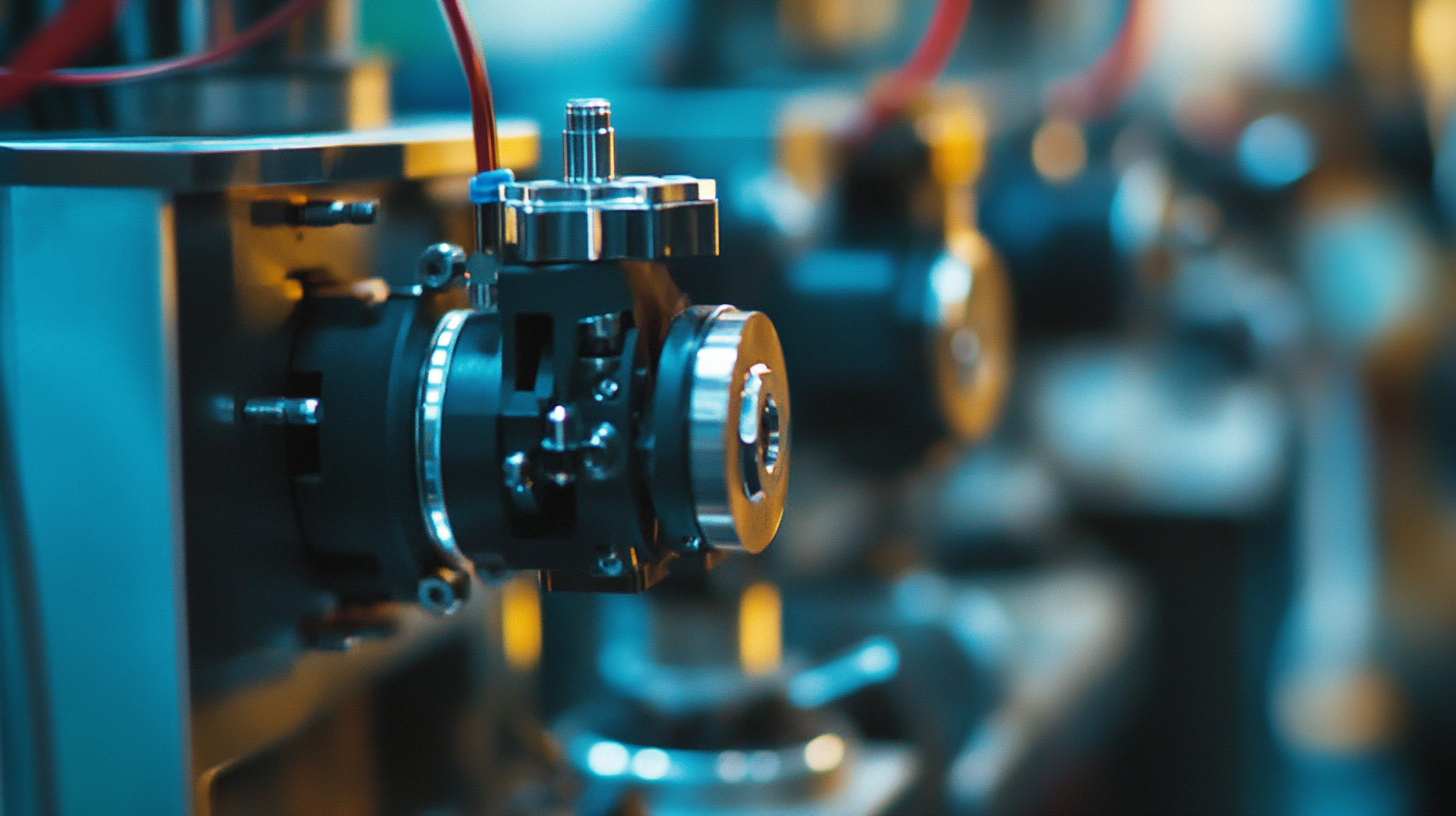

When selecting stepper motors for industrial applications, several key factors must be considered to ensure optimal performance and reliability. One of the primary considerations is the motor's torque rating. According to a report by the International Electrotechnical Commission (IEC), stepper motors can deliver a holding torque ranging from 0.5 to 12 Nm, depending on size and design. Understanding the torque requirements of your specific application is crucial, as insufficient torque can lead to missed steps and reduced accuracy in positioning tasks.

Another critical aspect is the step angle, usually measured in degrees, which affects the motor's resolution and smoothness of operation. Most stepper motors operate with step angles ranging from 0.9° to 1.8°. A smaller step angle can provide finer resolution, which is particularly advantageous in applications requiring high precision, such as CNC machines and 3D printers. Additionally, temperature ratings and cooling methods should not be overlooked. A study published by the American Society of Mechanical Engineers (ASME) highlights that maintaining optimal operating temperatures significantly enhances motor lifespan and performance efficiency. Therefore, assessing your specific needs regarding torque, step angle, and thermal management is essential for choosing the right stepper motor for your manufacturing processes.

| Feature | Description | Importance Level |

|---|---|---|

| Torque | The amount of rotational force the motor can provide. | High |

| Step Angle | The angle the motor turns for each step, affecting precision. | Medium |

| Voltage Rating | The voltage level needed for proper operation. | High |

| Current Rating | The maximum current the motor can handle safely. | High |

| Holding Torque | The torque the motor maintains when stationary. | High |

| Size and Weight | Physical dimensions and mass of the motor. | Medium |

| Heat Management | Ability of the motor to dissipate heat during operation. | High |

| Cost | The price of the motor in relation to budget constraints. | Medium |

Stepper motors play a crucial role in various industrial applications, each type tailored for specific needs. The two main categories of stepper motors are permanent magnet and variable reluctance types. Permanent magnet stepper motors are known for their high torque at low speeds, making them ideal for applications requiring precise control, such as robotics and CNC machines. On the other hand, variable reluctance stepper motors offer higher speed but lower torque, which can be suitable for applications in automated systems where speed is prioritized.

When selecting the best stepper motor for your needs, consider factors such as the application's required torque, speed, and stepping resolution. According to market analysis reports, the stepper motor market is projected to grow significantly, driven by sectors such as automotive and robotics. For instance, AC stepper motors dominate the market due to their low power consumption, while DC motors are often favored for their simplicity and cost-effectiveness.

**Tips**: Ensure compatibility with your control system, as some stepper motors require specific driver types. Additionally, evaluating the environmental conditions where the motor will be used, such as temperature and humidity, can greatly impact performance and longevity. Always consider future scalability to accommodate potential increases in demand or process changes.

This chart displays the torque ratings for different types of stepper motors commonly used in industrial applications. The NEMA 17, NEMA 23, NEMA 24, and NEMA 34 motors have varying torque outputs suitable for different workloads.

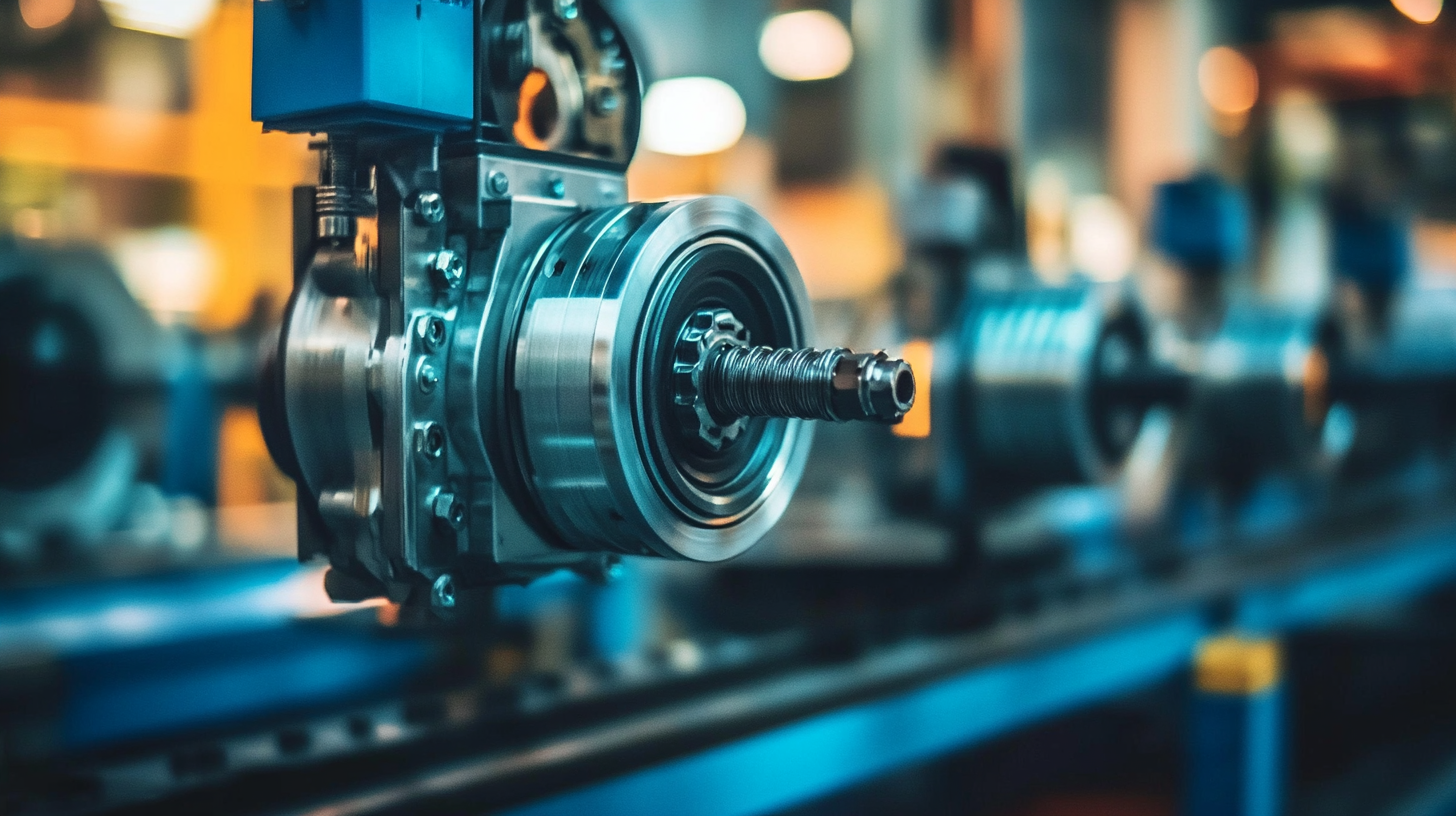

When selecting the best stepper motors for industrial applications, evaluating performance metrics is crucial to ensuring optimal functionality and efficiency. Key factors to consider include torque ratings, holding torque, and step angle. Torque ratings provide insight into the motor's ability to perform specific tasks under varying loads. Higher holding torque is essential for applications where the motor must maintain position against external forces, while a smaller step angle allows for smoother and more precise movements, particularly in applications that require high-resolution control.

Additionally, thermal performance and speed capabilities should also be assessed. The thermal characteristics indicate how well a stepper motor can handle prolonged use without overheating, which is vital in demanding environments. Speed capabilities, defined by the motor's step rate and acceleration, directly influence the machine's overall productivity. By carefully assessing these performance metrics, businesses can select the most suitable stepper motors that not only meet their specific requirements but also enhance the reliability and efficiency of their industrial processes.

When selecting stepper motors for industrial applications, two critical factors come into play: cost-effectiveness and long-term reliability. According to a recent report by Research and Markets, the global stepper motor market is projected to reach $4.5 billion by 2025, driven largely by the increasing demand for automation in manufacturing and the need for precision control in various applications. This growth underscores the importance of choosing a motor that not only meets initial cost requirements but also offers significant value over the product's lifecycle.

Long-term reliability is another essential consideration when choosing stepper motors. A study published in the IEEE Transactions on Industrial Electronics highlights that stepper motors can operate effectively with minimal maintenance and a failure rate significantly lower than that of traditional DC motors—often as low as 1% in the first five years of operation. This reliability translates to reduced downtimes and extends the lifespan of production equipment, making well-chosen stepper motors an economically sound investment. Companies that take the time to evaluate the right stepper motor, considering both upfront costs and potential long-term savings, can greatly enhance their operational efficiency.

Long-term reliability is another essential consideration when choosing stepper motors. A study published in the IEEE Transactions on Industrial Electronics highlights that stepper motors can operate effectively with minimal maintenance and a failure rate significantly lower than that of traditional DC motors—often as low as 1% in the first five years of operation. This reliability translates to reduced downtimes and extends the lifespan of production equipment, making well-chosen stepper motors an economically sound investment. Companies that take the time to evaluate the right stepper motor, considering both upfront costs and potential long-term savings, can greatly enhance their operational efficiency.