-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the rapidly evolving landscape of automation, businesses are continually seeking innovative solutions to enhance efficiency and precision in their operations. As industries strive for higher productivity, the importance of selecting the right technology becomes paramount. An Industrial Servo Motor stands out as a critical component in modern automation systems, offering unparalleled control and responsiveness. According to Dr. Emily Choi, a leading expert in industrial automation, "The integration of Industrial Servo Motors into manufacturing processes not only streamlines operations but also significantly boosts output quality."

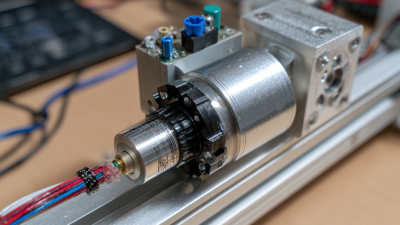

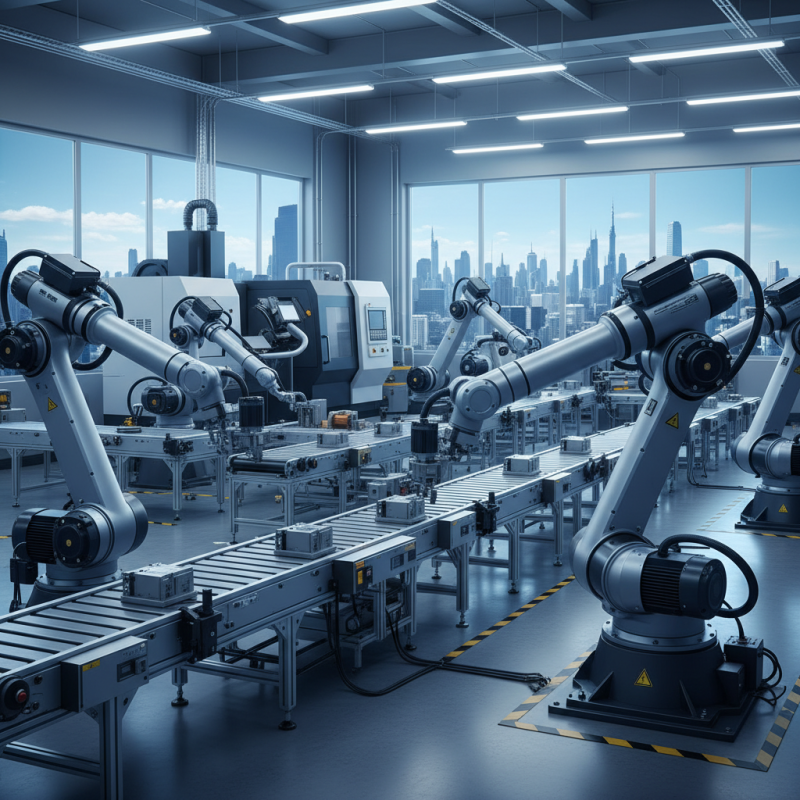

The capabilities of Industrial Servo Motors allow them to handle complex motion control applications with ease, making them ideal for robotics, conveyor systems, and CNC machinery. These motors provide exceptional accuracy and speed, enabling manufacturers to achieve precise movements that are essential for high-quality production. As organizations increasingly adopt automation technologies, understanding the benefits and applications of Industrial Servo Motors can provide a strategic advantage in a competitive marketplace.

Furthermore, the adaptability of Industrial Servo Motors facilitates their use across various sectors, from automotive to pharmaceuticals, underscoring their versatility and reliability. As industries continue to embrace automation for operational excellence, the choice of an Industrial Servo Motor may well define the future success of their automation initiatives.

Industrial servo motors are becoming increasingly essential in automation applications due to their precision, efficiency, and reliability. According to a 2022 report by MarketsandMarkets, the global servo motor market is projected to reach $11.26 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth is driven by a surge in demand for automation in manufacturing processes. Industrial servo motors provide highly accurate control over speed, position, and torque, enabling manufacturers to optimize their operations and improve overall productivity.

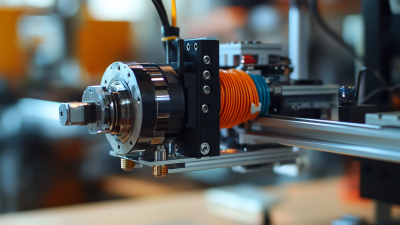

One of the primary benefits of industrial servo motors is their ability to deliver high performance combined with energy efficiency. A study conducted by the International Energy Agency (IEA) revealed that implementing servo drives in automation systems can lead to energy savings of up to 30-50% compared to traditional systems. Furthermore, servo motors can operate efficiently in a wide range of environments and are often equipped with advanced feedback control systems that ensure exceptional accuracy and responsiveness. This level of performance not only enhances production quality but also reduces wear and tear on machinery, resulting in lower maintenance costs and extended equipment lifespan.

Moreover, the adaptability of servo motors makes them suitable for various applications, from robotics and conveyor systems to CNC machinery. Their ability to integrate seamlessly with modern control systems enhances the flexibility of production lines, allowing manufacturers to quickly reconfigure their setups to meet changing demands. As industries increasingly shift toward smart manufacturing and Industry 4.0, the role of industrial servo motors will continue to be pivotal in achieving automation goals and driving innovation.

When considering automation needs in industrial environments, selecting the appropriate drive system is crucial for optimal performance and efficiency. Servo motors stand out for their high precision and responsiveness compared to alternative drive systems like stepper motors or DC motors. A study by the International Society of Automation highlights that servo motors can maintain an accuracy of ±0.1%, significantly outperforming typical stepper motors which can achieve accuracy within ±1% under certain conditions. This level of precision is vital for applications requiring tight tolerances, such as robotics and CNC machining.

Furthermore, servo motors excel in dynamic performance metrics, offering faster response times and higher torque-to-weight ratios. According to a market report from Research and Markets, servo motors can deliver torque ratings up to 10 times higher than traditional drive systems, while also minimizing energy consumption. This efficiency translates to lower operational costs, making servo motors a preferred choice for manufacturers looking to maximize productivity.

**Tip:** When evaluating drive systems, consider the specific application requirements such as load capacity, speed, and precision. Conducting a thorough analysis of your operational needs will help you select the most suitable motor type.

Additionally, servo motors typically come equipped with advanced feedback systems that enable precise control over their motion. This self-correcting capability enhances the reliability and longevity of the motor, reducing downtime and maintenance costs. According to industry analysis, implementing servo solutions can lead to a 15-30% increase in system efficiency, underscoring their value in modern automation frameworks.

**Tip:** Regularly assess your automation technology and seek updates to integrate the latest servo motor advancements, which can further improve system performance and adaptability.

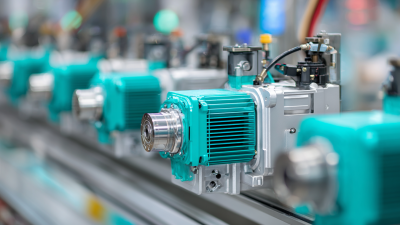

The manufacturing sector is experiencing significant growth in the adoption of industrial servo motors, driven by the need for precision, efficiency, and automation. As industries continue to evolve with the integration of advanced technologies, the demand for servo motors, which provide accurate control of position, velocity, and torque, has surged. This trend is particularly evident in sectors such as automotive, electronics, and packaging, where automation is essential for optimizing production processes and enhancing product quality.

Market analysts project a robust upward trend in the industrial servo motor market, fueled by the rising need for automation solutions that improve operational efficiency. The shift towards smart factories and Industry 4.0 has intensified the utilization of servo motors, as they offer superior performance in complex applications. Additionally, manufacturers are increasingly investing in robotics and automated systems, further propelling the demand for these motors. The ongoing innovations in motor technology, including increased energy efficiency and better integration with digital control systems, are expected to keep driving this growth trajectory in the coming years.

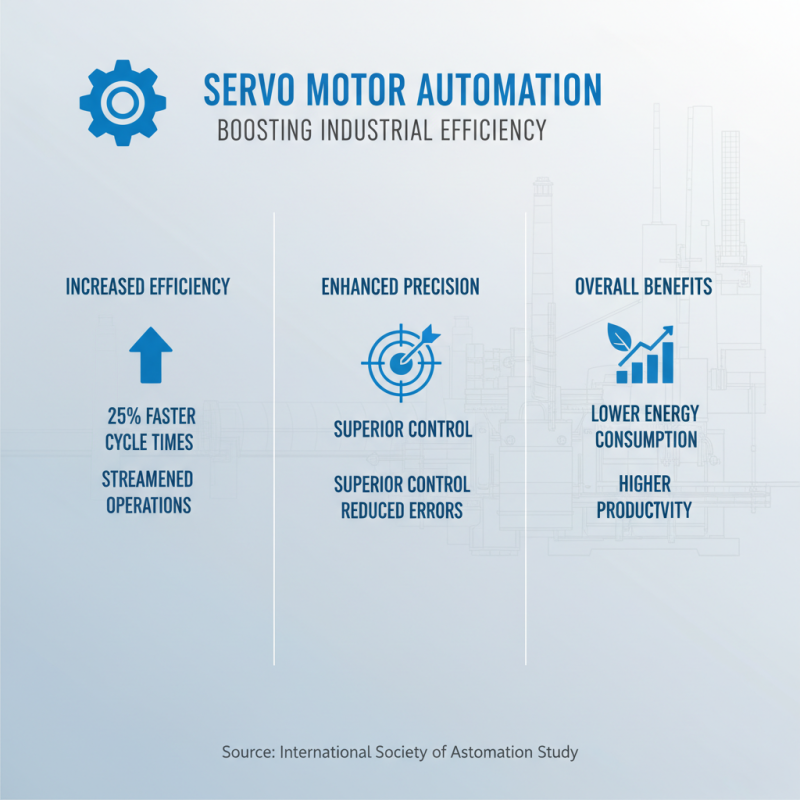

In modern industrial automation, the adoption of servo motors has proven to enhance efficiency and precision significantly. A study conducted by the International Society of Automation indicates that facilities utilizing servo motors can achieve a 25% increase in cycle time efficiency compared to traditional motor systems. This efficiency not only streamlines operations but also reduces energy consumption, reflecting an overall improvement in productivity.

One notable example is in the automotive industry, where servo motors have been integrated into robotic assembly lines. A case study from a major automotive manufacturer revealed that the implementation of servo technology not only improved assembly accuracy by 30% but also reduced the overall assembly time by 15%. Furthermore, the flexibility afforded by servo motors allows for rapid reconfiguration of production lines, accommodating varying product specifications without significant downtime.

In the packaging sector, another case study highlights the successful transition to servo-driven systems that enhanced the speed and precision of packaging processes. Reports indicate that companies experienced a 40% reduction in material waste due to more accurate placement and cutting, while simultaneously increasing throughput. The ability of servo motors to deliver consistent performance under demanding conditions has established them as a cornerstone in the evolution of industrious automation.

The evolution of servo motor technology is poised to redefine automation solutions across various industries. As businesses increasingly lean towards automation to enhance efficiency and productivity, innovations in servo motors play a crucial role. Recent reports indicate that the global servo motor market is projected to reach approximately $12 billion by 2025, highlighting a compound annual growth rate (CAGR) of around 5.5% from 2020. This growth underscores the demand for advanced precision control and energy efficiency that modern servo motors provide.

One key area of innovation is the integration of artificial intelligence and machine learning into servo motor systems. These technologies allow for real-time data analysis and adaptive performance, resulting in improved accuracy and responsiveness in automated tasks. According to a recent study by industry experts, AI-enabled servo motors can enhance operational efficiency by up to 30%, making them an attractive option for manufacturing processes that require high precision and reliability. Additionally, advancements in materials, such as lightweight composites and improved magnetic materials, are reducing the size and increasing the power density of servo motors, further driving their adoption in compact machinery and robotics.

The future of servo motor technology also sees an emphasis on sustainability, with manufacturers exploring greener alternatives and energy-efficient designs. Reports suggest that energy-efficient servo motors can reduce electric consumption by 20-30% compared to traditional models, making them not only a smart economic choice but also a viable option for companies aiming to reduce their carbon footprint. As these innovations continue to emerge, industries will benefit from enhanced automation solutions that are not only effective but also aligned with global sustainability goals.

| Feature | Description | Benefits | Future Innovations |

|---|---|---|---|

| High Precision | Provides accurate positional control | Improved product quality and consistency | Integration of AI for enhanced feedback systems |

| High Torque Density | Offers greater power in a smaller size | Space-saving design for compact installations | Development of ultra-compact motors with advanced materials |

| Energy Efficiency | Minimizes energy consumption during operation | Reduced operational costs | Smart energy-saving features leveraging IoT |

| Easy Integration | Seamless compatibility with existing systems | Faster setup and deployment | Modular designs for better adaptability |

| Durability | Designed for demanding industrial environments | Longer lifespan and reduced maintenance costs | Use of advanced materials to improve resilience |