-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

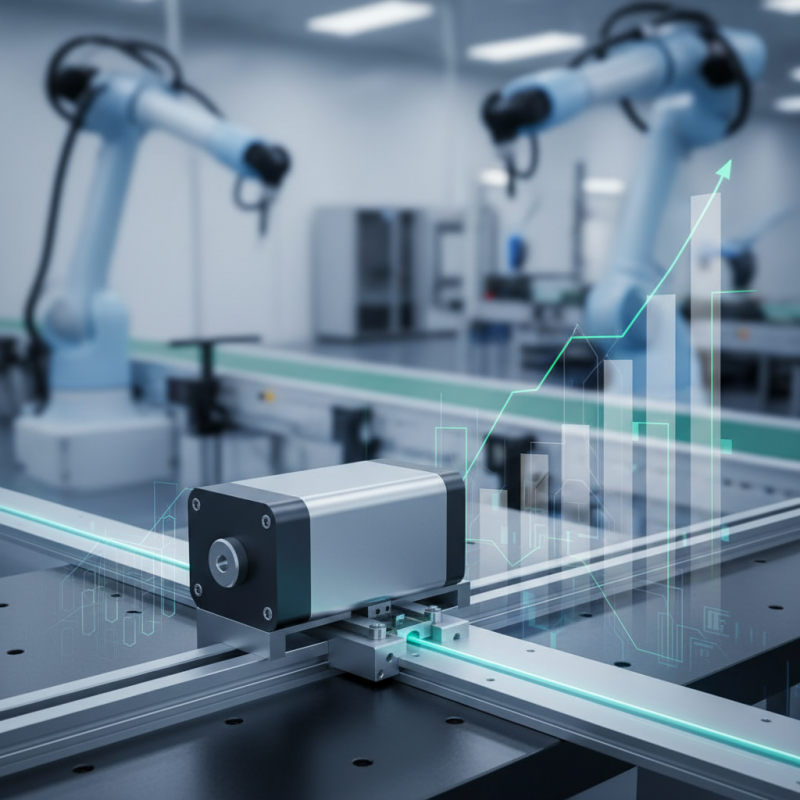

The choice of a Linear Servo Motor can significantly impact project success. Industry data shows that linear servo motors provide precision and efficiency. According to a 2022 market report, the global linear motion market is expected to grow by 7% annually. This rise demonstrates increasing demand for reliable automation solutions.

Linear servo motors offer quick response times and low maintenance options. Their design is compact, which saves valuable space in systems. A recent study found that 80% of engineers prefer linear servos for applications requiring high accuracy. However, potential challenges exist. The initial cost can be higher than traditional motors. Regardless, many find the benefits outweigh the risks.

Furthermore, integrating this technology may require training. Not all teams are familiar with the latest linear servo motor specifications. Sometimes, the complexity can be intimidating. Yet, embracing these advancements is crucial for staying competitive in today's fast-paced market. Companies willing to adapt will find significant advantages.

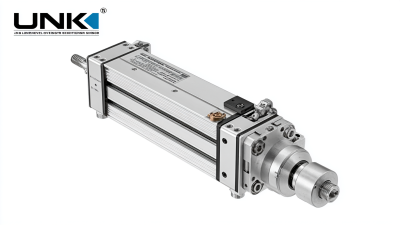

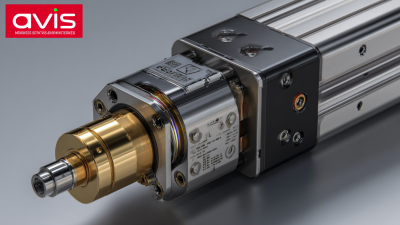

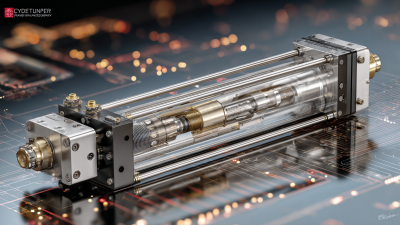

Linear servo motors are vital in automation and robotics. They convert electrical energy into precise linear motion. Understanding their functionality is crucial for effective application. These motors feature closed-loop control systems. This enables accurate positioning and speed control.

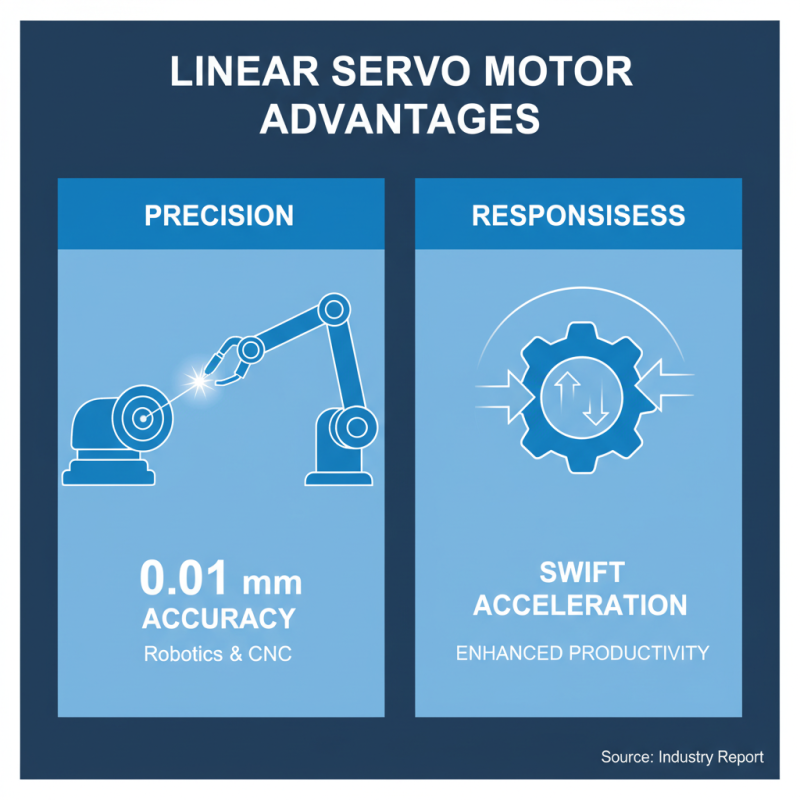

Typically, linear servo motors offer high precision. According to industry reports, some systems achieve positioning accuracy of ±0.01 mm. This level of precision is essential in sectors like manufacturing and aerospace. Linear servo motors also excel in dynamic response. They can reach high speeds and accelerate quickly, commonly up to 10 m/s.

Tips: Consider the load requirements of your application. Choose a motor that can handle the weight effectively. Don’t overlook thermal management. Overheating can reduce performance and lifespan.

With the right motor, projects thrive. The challenges can be intricate. Matching a motor to specific needs often requires a thorough assessment. Keep testing various configurations. This approach ensures optimal performance.

| Specification | Description | Advantages | Applications |

|---|---|---|---|

| Type | Electromechanical device that provides linear motion control | High precision and accuracy in positioning | Robotics, CNC machinery, automated assembly |

| Speed | Can achieve high speeds, often over 2 m/s | Increased productivity and efficiency | Packaging, material handling, press automation |

| Control | Closed-loop control systems for feedback | Enhanced performance and reliability | 3D printing, medical devices, semiconductor manufacturing |

| Load Capacity | Capable of handling various loads based on design | Versatility in application for different industries | Textile machines, automotive assembly, lab automation |

| Durability | Built for long operational life and reduced maintenance | Lower total cost of ownership | Food processing, pharmaceuticals, electronics assembly |

Linear servo motors offer distinct advantages for various projects. Their precision is unmatched. According to a recent industry report, these motors can achieve positioning accuracies within 0.01 mm. Such precision is crucial in applications requiring exact movements, like robotics and CNC machinery. The responsiveness of linear servo motors is also noteworthy. They can accelerate and decelerate swiftly, enhancing productivity in automated systems.

Another compelling benefit is efficiency. Linear servo motors often exhibit over 90% energy efficiency, as noted in research from the ElectroMechanical Systems group. This efficiency reduces operational costs and extends the lifespan of the equipment. However, some engineers struggle with integration issues, which can be complex. Understanding the system dynamics is essential to mitigate potential challenges.

Maintenance is another aspect worth considering. Despite their advantages, linear servo systems may require more upkeep than traditional setups. Regular monitoring helps in early detection of issues. Projects may benefit from not solely relying on these motors but balancing them with alternative technologies. This reflective approach ensures optimal performance and longevity of the entire system.

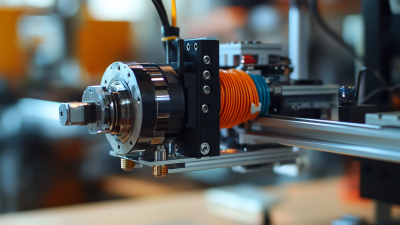

Linear servo motors are increasingly popular across multiple industries due to their precision and reliability. These motors excel in automation, where repetitive tasks demand accuracy. In manufacturing, they are used for precise positioning of tools and components. This ensures higher quality products with reduced errors. They help streamline processes, but over-reliance on technology can lead to issues.

In the medical field, linear servo motors drive essential machinery. From robotic surgical tools to patient handling systems, precision is crucial. The ability to control movement with minimal delay makes these motors invaluable. However, this reliance raises concerns about potential malfunction and maintenance costs.

The automotive industry also benefits from linear servo motors. They are instrumental in assembly lines, enhancing production speed. Engineers appreciate their adaptability in various applications. Yet, challenges remain, such as the need for advanced programming skills. As industries evolve, the integration of linear servo motors must be approached with care and foresight.

When comparing linear servo motors to other actuation technologies, several aspects come into play. Linear servo motors offer high precision and speed, which are crucial in applications like CNC machining. According to recent industry reports, they can achieve positioning accuracy within ±0.01 mm. This is a significant advantage over pneumatic systems, typically around ±0.5 mm. Moreover, the response time of linear servos is often less than 20 milliseconds, vastly outperforming traditional hydraulic systems that can lag due to fluid dynamics.

Another factor to consider is energy efficiency. Linear servo motors generally consume less energy for the same output compared to many other actuation types. Data indicates that electromechanical systems, like linear servos, can reduce energy consumption by up to 30% compared to pneumatic systems. This efficiency not only lowers operating costs but also contributes to sustainability goals. Despite these benefits, some designers might find the initial investment cost to be a drawback. The complexity of integration into existing systems can also raise concerns.

In real-world applications, minimal installation space poses challenges. Designers must assess whether the compact nature of linear servo motors can fit into existing setups. Furthermore, maintenance requirements differ across technologies, making ongoing costs variable. A detailed understanding of project requirements helps navigate these intricacies.

When selecting a linear servo motor, it’s crucial to weigh a few important factors. First, consider your project's specific needs. What speed do you require? Different tasks demand different speeds. A fast-moving application needs a motor with a higher torque-to-weight ratio. Always match the motor's speed with the application.

Next, think about the space available. If you have a compact design, you may require a smaller motor. Be aware that a tiny motor might not deliver the force you need. Balance size and power is essential.

**Tip:** Evaluate the weight the motor must move. This will affect your choices greatly.

Feedback and precision are also key factors. A good linear servo motor should provide accurate positioning. This is especially important in automation or robotics. If exact positioning is critical, ensure the motor meets your accuracy criteria. Sometimes, manufacturers provide a wide range of models, making it easy to choose the wrong one.

**Tip:** Always review performance charts. They often reveal the motor’s true capabilities.

Lastly, consider budget constraints. Cheaper options may lack features or reliability. A costly motor isn’t always the best choice. Research carefully to find a motor that fits both your needs and budget.