-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the rapidly evolving world of automation, selecting the right Delta Servo Motor is crucial for optimizing performance and efficiency in various applications. With the global servo motor market projected to reach $10.57 billion by 2027, driven by advancements in robotics and industrial automation, the importance of making an informed decision has never been greater. According to a recent report by Research and Markets, Delta Servo Motors are renowned for their precision, reliability, and ease of integration, making them a preferred choice among manufacturers. As industries strive for higher productivity and lower operational costs, understanding the factors that influence the selection of the right servo motor—such as load requirements, speed, and control options—becomes imperative. This blog aims to guide you through the essential considerations when choosing a Delta Servo Motor, ensuring that your automation needs are met with the highest efficiency.

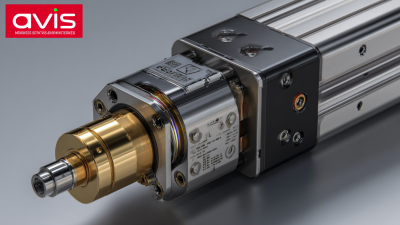

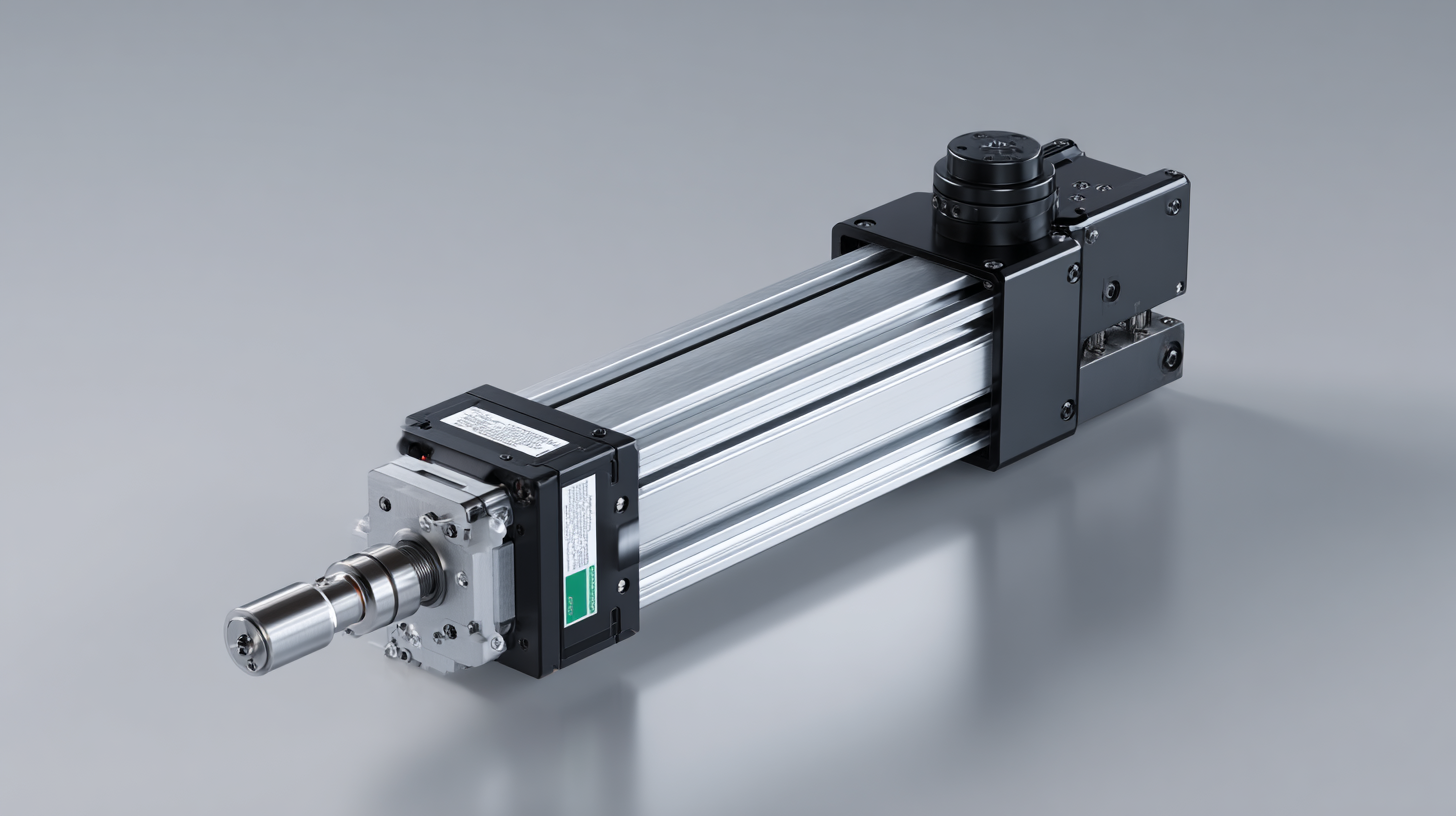

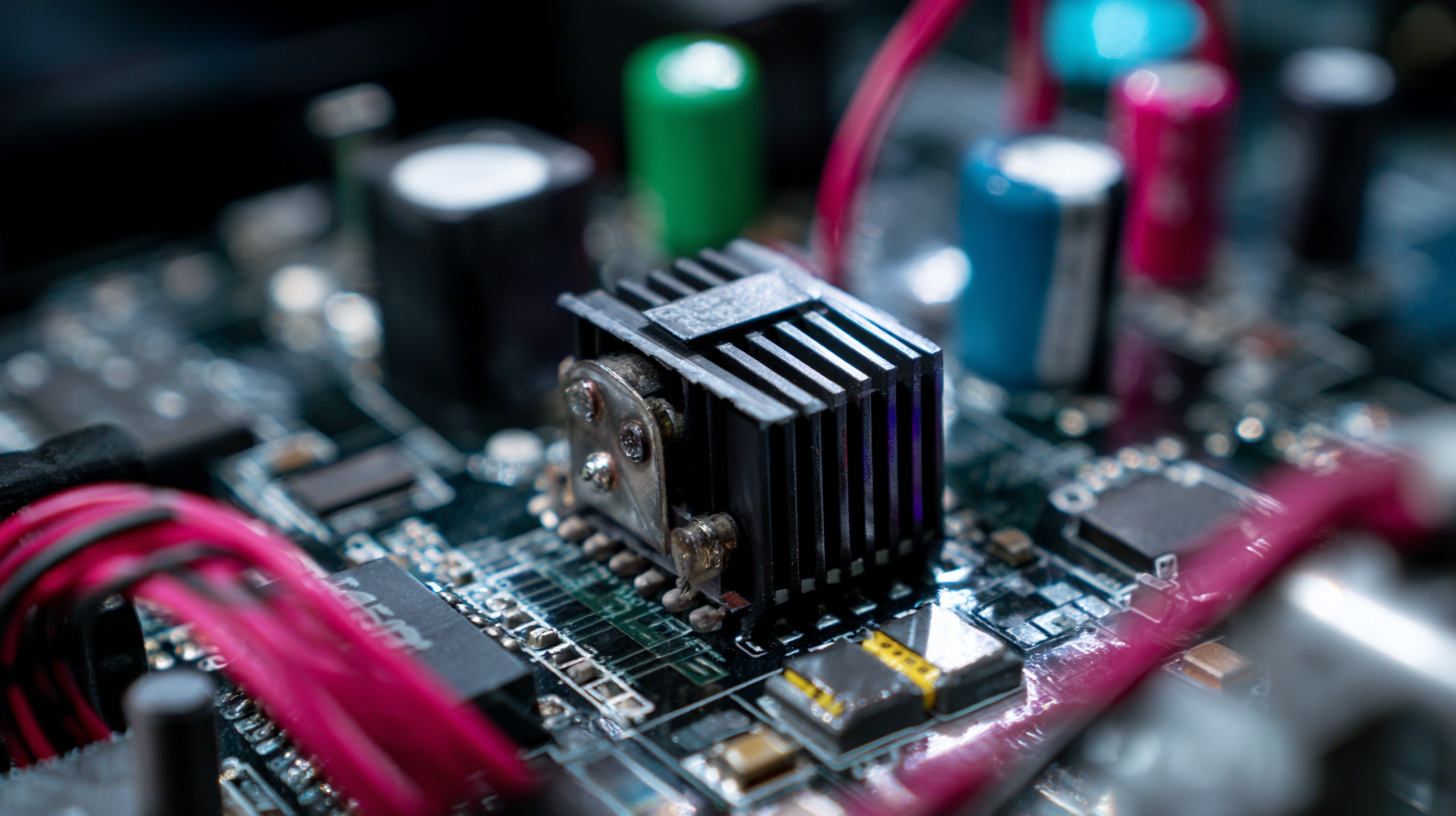

When selecting a Delta servo motor for your automation needs, it's essential to understand the key features and benefits that differentiate these systems from others in the market. Delta servo motors are engineered for precision and reliability, making them ideal for a range of applications, from CNC machinery to packaging solutions. Their advanced control capabilities allow for smooth operation and exceptional response times, which are crucial in high-speed environments.

One significant advantage of Delta servo motors lies in their adaptability to various input power specifications, which facilitates integration into existing systems. Recent innovations, such as those showcased at industry trade shows, highlight the expanding range of power outputs suitable for different applications, ranging from small-scale to heavy-duty operations. With features that enhance energy efficiency and reduce maintenance costs, Delta servo motors provide a compelling value proposition for businesses looking to optimize their production processes and minimize downtime.

When selecting a Delta servo motor for your automation projects, understanding your specific requirements is crucial. Start by evaluating the load you'll be handling. This includes not only the weight of the components but also the dynamic forces involved during operation. A motor that is too weak can lead to performance issues, while an overpowered motor may waste energy and increase costs. Therefore, accurately determining the load characteristics—static and dynamic—is the first step in ensuring optimal motor performance.

When selecting the right servo motor for your automation projects, torque, voltage, and control methods are crucial specifications to consider. Torque is a fundamental measure of a motor's ability to perform work; for instance, servo motors typically offer a wide range of torque outputs, enabling them to handle various loads effectively. According to industry reports, servo motors with higher torque densities not only enhance performance but also improve energy efficiency, which is paramount for reducing operational costs.

Voltage is another key specification. Choosing the appropriate voltage ensures compatibility with your existing systems and affects the motor's overall performance. A motor operating below its rated voltage can underperform, while one running at a higher voltage may lead to overheating and damage. Therefore, understanding your system's voltage requirements is essential for optimal motor selection.

**Tips:** When evaluating control methods, consider advanced techniques such as Direct Torque Control (DTC) and Space Vector Modulation. These methods not only improve torque ripple reduction but also enhance responsiveness and precision in servo applications. Additionally, integrating soft computing approaches, such as fuzzy logic, can dynamically adjust the motor's performance based on real-time load conditions, further optimizing operation.

When selecting the right Delta servo motor for your automation needs, understanding the various models and their performance capabilities is essential. Delta offers a diverse range of servo motors designed for different applications, from high-speed operations to precise motion control. For instance, the ASDA-A2 series is known for its high torque density and is ideal for applications requiring rapid acceleration and deceleration. In contrast, the ASDA-A3 series introduces advanced control algorithms that enhance stability and responsiveness in dynamic environments, making it suitable for robotics and CNC machinery.

Moreover, application suitability should guide your choice. The Delta servo motors come equipped with features tailored for specific sectors. The ASDA-M series stands out in packaging and material handling due to its robust design and resistance to environmental factors, while the ASDA-B series is engineered for general-purpose applications, offering flexibility and ease of integration. By evaluating both the performance metrics and the specific requirements of your application, you can make an informed decision that maximizes efficiency and productivity in your automation projects.

| Model | Rated Power (kW) | Rated Torque (Nm) | Maximum Speed (RPM) | Application Suitability |

|---|---|---|---|---|

| Model A | 0.75 | 2.5 | 3000 | Light-duty applications |

| Model B | 1.5 | 5.0 | 3500 | Medium-duty applications |

| Model C | 3.0 | 10.0 | 2000 | Heavy-duty applications |

| Model D | 5.0 | 20.0 | 1500 | Industrial robotics |

Choosing the right Delta servo motor involves more than just technical specifications; it also hinges on critical factors like cost, support, and supplier reliability. Cost is a primary concern for many businesses, as it directly impacts the overall budget for automation projects. It is essential to weigh the initial investment against the long-term benefits the servo motor will bring. While opting for the cheapest alternative may seem appealing, it's crucial to consider the potential hidden costs associated with lower quality, including maintenance and downtime issues.

Equally important is the level of support offered by the supplier. A reliable supplier should provide robust customer service, including technical assistance, readily available spare parts, and comprehensive warranties. This is particularly vital during the installation and integration phases, as well as throughout the operational life of the equipment. Engaging with suppliers who have a track record for quick resolution of issues can prevent costly disruptions in production. Furthermore, evaluating supplier reliability, including their financial stability and reputation within the industry, will ensure you have a partner who can support your automation journey effectively.