-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the rapidly evolving landscape of automation and robotics, selecting the right stepper motors is crucial for the success of any project in 2025. The global stepper motor market is projected to grow at a CAGR of 8.1% from 2020 to 2025, reaching a value of approximately $4.3 billion by 2025, according to a recent report by MarketsandMarkets. This growth is driven by the increasing demand for precision motion control in industries such as manufacturing, healthcare, and consumer electronics. The ability of stepper motors to provide accurate positioning and repeatability makes them a preferred choice for engineers and developers alike.

Expert insights further underscore the importance of choosing the appropriate stepper motors. Dr. Emily Richards, a leading authority in motion control systems, emphasizes, "The effectiveness of a project often hinges on the selection of the right stepper motor – it can mean the difference between success and failure." As developers tackle more sophisticated applications in 2025, understanding the specifications, torque, and drive configurations of stepper motors will be critical. Informed decision-making in this area not only enhances operational efficiency but also paves the way for innovation in various applications, from 3D printing to robotics and beyond.

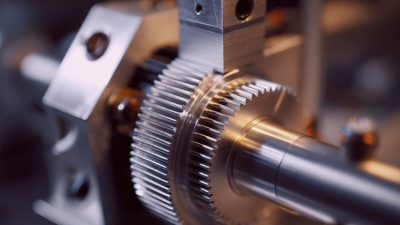

Understanding the basics of stepper motors is crucial for selecting the right one for your projects in 2025. Stepper motors operate by dividing a full rotation into a number of equal steps, allowing precise control over angular position. This feature makes them ideal for applications that require accurate positioning, such as robotics and CNC machines. Common types include permanent magnet, variable reluctance, and hybrid stepper motors, each offering distinct advantages depending on the application.

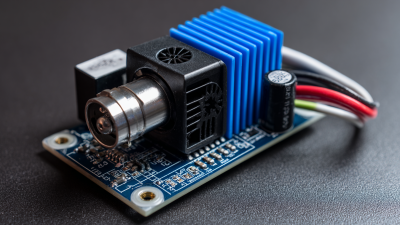

Microstepping, a technique used to enhance stepper motor performance, allows for smoother and more precise motion. By subdividing each full step into smaller increments, microstepping reduces vibration and improves control precision. Understanding the driving methods—such as full-step, half-step, and microstepping—is essential for optimizing motor performance in your projects. With advancements in technology, integrating stepper motors with microcontrollers can open up new possibilities, particularly in miniaturized systems like the Raspberry Pi Pico, where their size and capabilities can lead to innovative applications in automation and control systems.

When selecting stepper motors for projects in 2025, there are several key factors to consider to ensure optimal performance and efficiency. Firstly, the torque requirements of your application play a crucial role in the selection process. According to a report from Research and Markets, the global stepper motor market is projected to reach $3.88 billion by 2025, highlighting a growing demand for high-torque solutions in various industries. Understanding the specific torque needed for your machinery will help you choose a stepper motor that can meet these needs without compromise.

Another significant factor is the step angle precision. Stepper motors typically come with different step angles, and the choice can affect the accuracy of your project's motion control. Industry experts suggest that motors with smaller step angles provide finer control and improved resolution, which is critical in applications such as robotics and CNC machinery. A recent study by Transparency Market Research indicates that applications requiring high precision are driving innovations in stepper motor technology, making it essential to evaluate your project's accuracy requirements before making a selection.

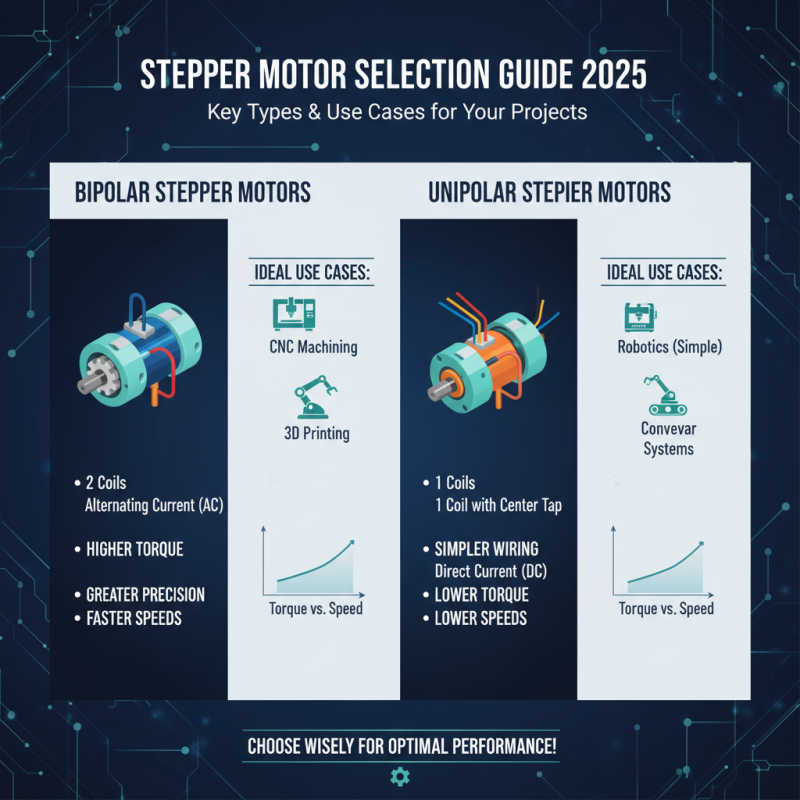

When selecting stepper motors for your projects in 2025, it's crucial to understand the common types and their ideal use cases. For instance, Bipolar stepper motors provide better torque and precision, making them suitable for applications that require high accuracy, such as CNC machining and 3D printing. These motors have two coils and operate on alternating current, enabling them to achieve greater torque at higher speeds.

In contrast, Unipolar stepper motors are often preferred for simpler control systems, thanks to their easier wiring and operation. They work well in applications that do not require extreme precision, such as basic robotic movements or automation projects. Additionally, hybrid stepper motors combine features of both bipolar and unipolar motors, offering greater versatility and efficiency, making them ideal for more complex systems where both high torque and positional accuracy are necessary. Understanding these differences can significantly enhance your project's performance and efficiency.

When evaluating performance specifications for stepper motors, one must consider several critical factors that can greatly affect the efficiency and efficacy of projects in 2025. Key specifications include torque, step angle, and operating voltage. According to a recent report by MarketsandMarkets, the global stepper motor market is expected to grow from $3.4 billion in 2020 to $5.2 billion by 2025, showcasing an increasing demand for precise control in automation and robotics applications. Torque ratings, which indicate the motor's ability to handle load, are essential; higher torque allows for smoother operation at higher speeds, significantly impacting performance in dynamic environments.

Additionally, step angle is a vital specification that defines the resolution of the motor. For instance, a common step angle of 1.8 degrees translates to 200 steps per revolution, providing a perfect balance between precision and control in many applications. A 2022 report from Technavio indicates that stepper motors with a smaller step angle (like 0.9 degrees) are gaining traction, particularly in high-precision applications, as they offer greater resolution and smoother motion. By understanding these specifications and their implications on overall performance, engineers and hobbyists can make informed decisions when selecting the right stepper motors to meet the evolving demands of their projects.

| Motor Type | Holding Torque (N.cm) | Step Angle (degrees) | Rated Current (A) | Voltage (V) | Weight (kg) |

|---|---|---|---|---|---|

| NEMA 17 | 45 | 1.8 | 1.68 | 12 | 0.38 |

| NEMA 23 | 76 | 1.8 | 2.8 | 24 | 0.68 |

| NEMA 34 | 134 | 1.8 | 6.0 | 48 | 1.68 |

| Ultra High Torque | 160 | 1.2 | 5.0 | 36 | 1.2 |

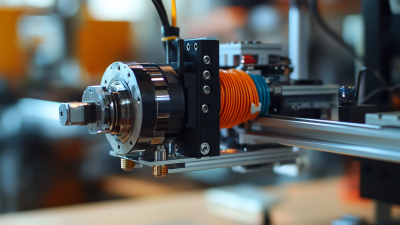

Integrating stepper motors into your projects in 2025 requires careful consideration of several key factors to ensure optimal performance. First, assess the specific application of your project. Different projects may require varying degrees of precision, torque, and speed, which are critical parameters of stepper motors.

For instance, high-precision tasks, such as CNC machines or 3D printers, will benefit from hybrid stepper motors that provide both accuracy and torque, while simpler applications may suffice with basic unipolar stepper motors.

Additionally, consider the control systems that will be used to drive the stepper motors. Modern integration often involves using advanced microcontrollers or dedicated motor drivers that support features like micro-stepping. This technique enhances smoothness and accuracy in motor movements, making it essential for applications requiring fine control. Moreover, ensure the power supply matches the motor specifications to avoid overheating or underperformance. By carefully selecting the right type and integrating the appropriate control technology, you can enhance your project's functionality and efficiency significantly.