-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the rapidly evolving world of automation, the choice of components can significantly influence system efficiency and performance. One of the most impactful decisions is the selection of actuators, with Servo Linear Actuators standing out due to their precision and versatility. Dr. Michael Anderson, a renowned expert in motion control systems, asserts, "Servo Linear Actuators provide unmatched accuracy and responsiveness, essential for modern automation applications." This highlights the critical role these components play in ensuring optimal system functionality.

As industries seek to enhance productivity and reduce operational costs, the demand for high-quality actuators is on the rise. The Servo Linear Actuator, with its ability to convert rotational motion into linear motion with exceptional control, offers solutions tailored for complex automation tasks. By integrating advanced technology and offering user-friendly features, these actuators empower manufacturers to achieve higher levels of operational excellence. Understanding why to choose Servo Linear Actuators will assist businesses in making informed decisions that align with their automation goals.

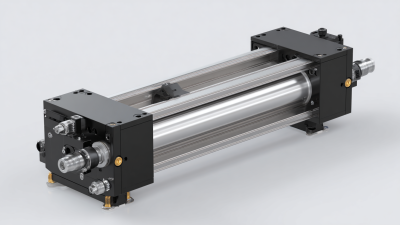

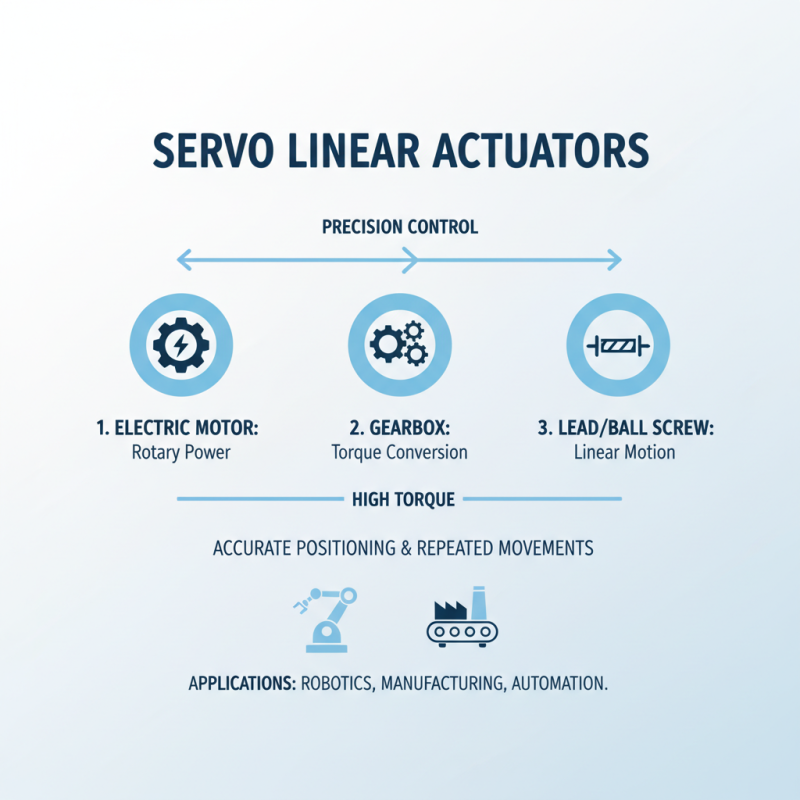

Servo linear actuators are essential components in automated systems, offering precision control and efficiency. These devices combine the benefits of servo motors with linear motion systems, allowing for accurate positioning and repeated movements. At their core, a servo linear actuator consists of an electric motor, a gearbox, and a lead screw or ball screw, which translates rotary motion into linear motion. This setup not only enhances the accuracy of movements but also sustains high levels of torque, making them suitable for a wide range of applications from robotics to manufacturing.

When considering a servo linear actuator, it's important to evaluate several factors to maximize performance. **Tip 1:** Assess the load requirements of your application. Knowing the weight and speed needed will help you select the right actuator size and specifications. **Tip 2:** Look at the precision needed for your tasks. Servo actuators can be finely tuned to deliver specific positions or speeds, so understanding your application’s requirements is key to optimizing performance.

Additionally, these actuators can be integrated easily with various control systems, enabling smoother automation processes. **Tip 3:** Consider the software compatibility and ease of integration into your existing systems. A well-integrated actuator can enhance overall productivity and efficiency in your automation projects, leading to better outcomes and reduced downtime.

Servo linear actuators are increasingly becoming a preferred choice in automation applications due to their exceptional precision and efficiency. These actuators combine the functionality of traditional linear actuators with the advanced control capabilities of servo motors, allowing for highly accurate positioning and movement. This is particularly beneficial in environments where precise control is essential, such as in robotics, packaging, and assembly lines. The ability to fine-tune speed, force, and position in real-time enables operators to achieve optimal performance without sacrificing reliability.

In addition to their precision, servo linear actuators are renowned for their energy efficiency. They consume power only when in motion, reducing operational costs compared to other linear motion solutions that may draw power continuously. This energy-saving characteristic not only lowers electricity bills but also contributes to a smaller carbon footprint, making them a suitable choice for environmentally-conscious operations. Moreover, their compact design allows for integration into various systems without requiring significant modifications, facilitating faster implementation in complex automation setups. Overall, the adoption of servo linear actuators can significantly enhance the overall productivity and sustainability of automation applications.

| Feature | Description | Benefits |

|---|---|---|

| Precision | Servo linear actuators provide high accuracy in positioning and motion control. | Reduces errors in automation applications, enhancing product quality. |

| Speed | Capable of rapid movement and response times. | Increases overall system efficiency and throughput. |

| Durability | Built to withstand heavy workloads and harsh environments. | Lowers maintenance costs and extends equipment life. |

| Flexibility | Can be configured for various tasks and applications. | Allows for adaptability in dynamic production lines. |

| Energy Efficiency | Servo systems utilize energy effectively, adjusting power based on load requirements. | Reduces energy costs and enhances sustainability. |

| Integration | Easily integrates with existing automated systems. | Facilitates upgrades without major overhauls to infrastructure. |

When selecting a servo linear actuator for automation needs, focusing on performance metrics such as speed, precision, and load capacity is crucial. Speed is often a decisive factor, as many applications require rapid movements to enhance productivity. According to a 2021 industry report from the International Federation of Robotics, modern servo linear actuators can achieve speeds of up to 500 mm/s, significantly surpassing traditional linear actuators, which typically operate around 200 mm/s. This increased speed not only reduces cycle times but also allows for higher throughput in manufacturing environments.

Precision in automation processes is another critical metric. Servo linear actuators are designed to provide high positioning accuracy, often within ±0.01 mm. A report by the Association for Advancing Automation highlights that industries utilizing high-precision tasks, such as semiconductor manufacturing and precision assembly, can benefit from the advanced feedback systems and control algorithms inherent in servo actuators. These systems enable real-time adjustments, resulting in diminished errors and improved product quality.

Load capacity is equally important when evaluating actuator performance. Servo linear actuators can support various load weights, from light components to heavy machinery parts, with maximum capacities often exceeding 1000 kg. The same industry analysis indicates that as automation demands grow, particularly in sectors like automotive and aerospace, the necessity for robust load handling capabilities will only increase. Thus, selecting a servo linear actuator that can adequately meet these three key performance metrics will ensure optimal efficiency and reliability in automation systems.

The adoption of servo linear actuators is witnessing significant growth across various industries, driven by the increasing demand for precision and efficiency in automation processes. Recent market analysis indicates that the global servo actuator market is projected to reach approximately $9.5 billion by 2027, growing at a compound annual growth rate (CAGR) of around 6.8% from 2020 to 2027. This surge is primarily attributed to the rising automation in manufacturing and the need for enhanced process control in sectors such as automotive, electronics, and pharmaceutical manufacturing.

A vital factor contributing to the popularity of servo linear actuators is their ability to provide high torque and precise positioning in linear motion applications. According to a report by Research and Markets, the automotive sector is expected to be one of the fastest-growing areas for servo linear actuators, owing to the increasing trends towards electric vehicles and advanced driver-assistance systems (ADAS). Additionally, as industries continue to lean towards smart manufacturing, the integration of servo linear actuators enables more efficient operation, reduced cycle times, and improved overall productivity. This trend not only resonates with manufacturers aiming to optimize their processes but also aligns with the broader shift towards Industry 4.0, where automation plays a crucial role in sustaining competitive advantage.

When choosing the right actuator for automation needs, a comparative analysis of servo linear actuators and traditional actuators reveals significant advantages. Servo linear actuators provide high precision and efficiency, with the ability to control speed, position, and torque in real-time. According to a report by the International Federation of Robotics, the demand for precise motion control in manufacturing has increased by approximately 40% in the past five years, making servo technology increasingly relevant. Traditional actuators, while reliable, often lack the adaptability and responsiveness needed for advanced automation applications, leading to inefficiencies and increased operational costs.

One important aspect to consider is energy efficiency. Servo linear actuators typically consume less power as they only draw energy when needed, resulting in energy savings of up to 30% compared to traditional solutions. This not only reduces operational costs but also contributes to a company's sustainability goals. Furthermore, the integration of smart technology in servo systems allows for predictive maintenance, minimizing downtime and improving overall productivity.

Tips: When implementing new automation solutions, always conduct a thorough analysis of your specific application requirements. Assess factors such as load capacity, required speed, and environmental conditions to ensure you choose the actuator that best fits your operational needs. Additionally, consider always investing in training for your team – understanding the full capabilities of your chosen actuators can lead to improved efficiency and optimal performance in the long run.