-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In recent years, the adoption of Servo Motor Drives in automation has surged. According to a report by the International Federation of Robotics, the global market for servo systems is projected to grow at a rate of 7.5% annually. This growth highlights the increasing reliance on precision and efficiency in various industries.

Dr. Emily Nguyen, a leading expert in automation technology, emphasizes, "Servo Motor Drives are crucial for achieving high accuracy and speed in manufacturing processes." This statement reflects the industry's shift toward advanced solutions that boost productivity. Companies seeking to enhance performance often find that traditional systems fall short.

Choosing the right drive is critical. Servo Motor Drives offer better control, reduce energy consumption, and enhance operational reliability. However, businesses must carefully evaluate their specific needs. There can be challenges in integration and cost. Understanding how to leverage servo technology effectively can be the difference between stagnation and advancement in automation efforts.

Servo motor drives are increasingly popular in automation systems. Their precision is unmatched. According to a report by ResearchAndMarkets, the global servo motor market is projected to reach $19 billion by 2027. This growth reflects the demand for accuracy and efficiency in various applications.

One significant advantage of servo motors is their ability to provide high torque at low speeds. This feature minimizes energy waste. In a study by MarketsandMarkets, companies report a 30% increase in energy efficiency when switching from traditional motors to servo drives. This leads to reduced operational costs and improved productivity. Additionally, servo motors offer smoother control, which is essential for delicate applications.

While servo drives are beneficial, they are not without challenges. The initial investment can be higher than traditional systems. Some users may struggle with the complexity of setup. A lack of skilled technicians can hinder effective implementation. Despite these challenges, the advantages often outweigh the downsides. Organizations must weigh their options carefully before committing to a transition.

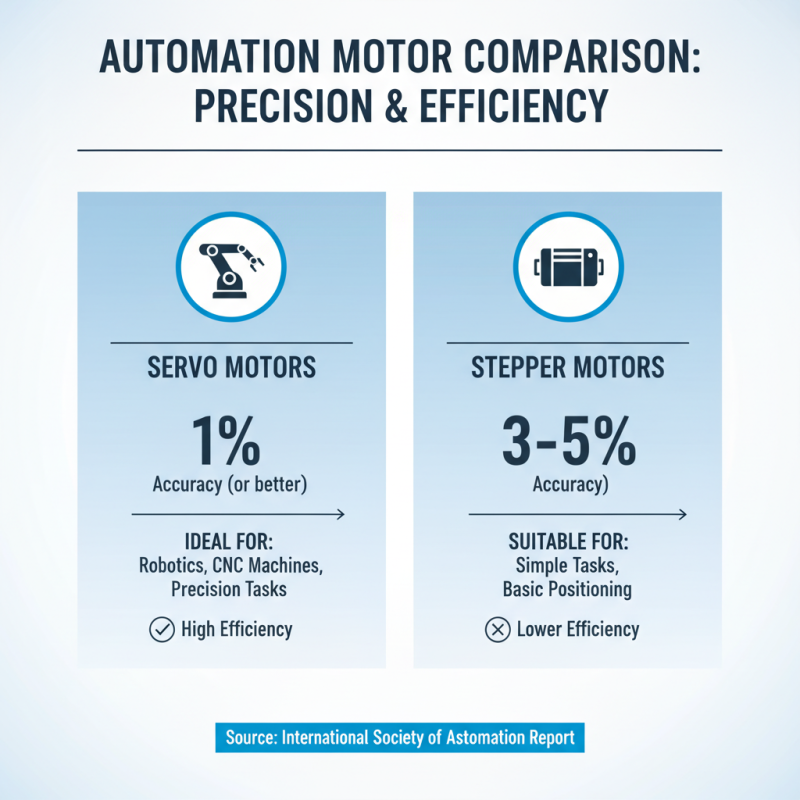

Servo motors stand out in automation for their precision and efficiency. According to a recent report by the International Society of Automation, servo systems can achieve accuracy levels within 1%. This makes them ideal for applications requiring exact movements, such as robotics and CNC machinery. In contrast, stepper motors offer only 3% to 5% accuracy. While stepper motors are simpler, their drawbacks in precision can lead to issues in complex tasks.

Another critical aspect is torque performance. Servo motors generate higher torque at varying speeds compared to DC and stepper motors. A study by the National Institute of Standards and Technology highlights that servo systems can maintain torque levels of up to 200% at startup. This capability allows for better handling of inertia-rich loads. However, the complexity of servo systems necessitates careful calibration. Poor tuning can hinder performance, leading to subpar results.

Cost factors also play a role in motor selection. While servo motors are often more expensive upfront, they provide better long-term value due to their energy efficiency. Industry data indicates that servo systems can reduce energy consumption by up to 30% when compared to traditional motor types. This statistic prompts a reflection: are the initial investments in servo technology justifiable for all applications? The decision hinges on the specific needs and operational goals of each automation task.

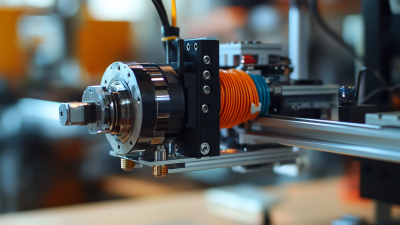

Servo motors offer distinct advantages for automation tasks. Their high precision in motion control significantly boosts efficiency. This makes them ideal for applications where accuracy is critical. The ability to maintain a constant speed, even under varying loads, is also a notable feature. This is essential for processes requiring consistent performance.

Another key attribute is the quick response time of servo motors. They can adjust their position rapidly, enhancing production rates. This speed can be crucial in environments where time is money. However, it's worth noting that not every project requires such quick adjustments. In some cases, simpler systems might suffice. This can lead to unnecessary complexity when a basic solution could work.

Furthermore, servo motors have feedback systems for constant monitoring. This leads to better fault detection and reduced downtime. Yet, these systems can sometimes complicate maintenance. Operators must understand both the hardware and software involved. It’s important for teams to receive proper training. Communication gaps could hinder efficiency if not addressed. Balancing these features with the project's needs is vital for success.

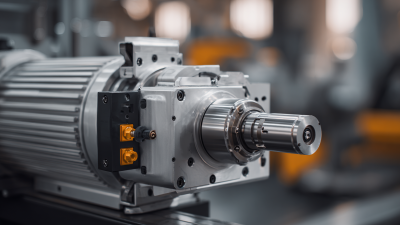

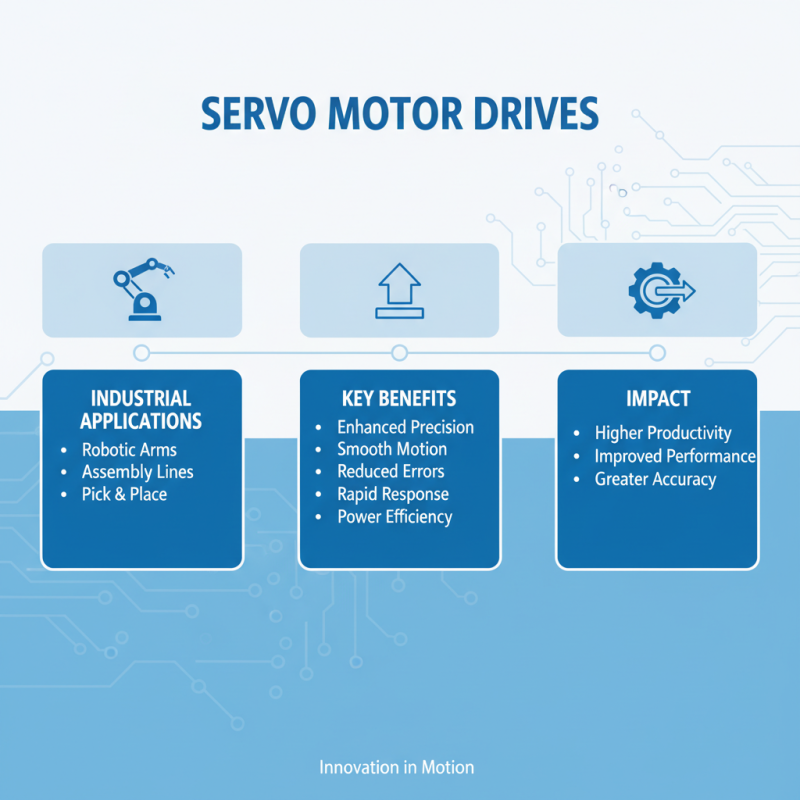

Servo motor drives are essential in various industries, enhancing performance and precision. In manufacturing, they control robotic arms with incredible accuracy. These motors ensure smooth movements, reducing errors in assembly lines. They are often used in pick-and-place applications, where speed is crucial. The rapid response and power efficiency allow for higher productivity.

In the automotive sector, servo drives play a critical role in machining and testing equipment. They are used for tasks like welding and painting, requiring precise control. The flexibility of servo systems enables adaptation to different tasks as needed. In packaging, servo motors streamline the process, ensuring consistent quality and speed. However, integration challenges sometimes arise, demanding careful planning and adjustments.

The food industry employs servo motors in bottling and labeling. These applications require hygiene and reliability. While servo drives offer numerous benefits, they need proper calibration. In medical devices, accuracy is paramount; one mistake can have serious implications. Balancing efficiency and safety can spark debate among engineers. Each application showcases the versatility of servo motors, revealing both strengths and areas for improvement.

When selecting a servo motor drive, several key considerations arise. Precision is crucial in automation applications. A report from the International Federation of Robotics highlights that 80% of manufacturing companies prioritize accuracy. In these systems, the right servo motor drive ensures movements are exact and repeatable. A mismatch in motor specifications can lead to errors. This is especially problematic in high-stakes environments like pharmaceuticals or aerospace.

Compatibility with existing systems is another vital factor. Many manufacturers underestimate the integration challenges. A study by the Automation Industry Association found that about 30% of automation projects run into trouble due to compatibility issues. It’s essential to assess the full system architecture before making a choice. A simple oversight can escalate project costs and timelines, detracting from overall efficiency.

Moreover, understanding the power requirements of your application is necessary. Different servo motors operate with varying voltage levels and power ratings. This can greatly influence performance. Too often, companies overlook these details, resulting in underperforming systems. Balancing torque requirements and speed capabilities is critical. The right analysis can prevent costly adjustments post-installation.

| Parameter | Importance | Considerations |

|---|---|---|

| Torque | High | Select a motor with adequate torque for your application requirements. |

| Speed | Medium | Consider the speed needed for your tasks and ensure the servo drive can accommodate it. |

| Precision | High | Ensure the chosen servo motor meets the precision requirements of your application. |

| Feedback System | High | Choose a servo drive with an appropriate feedback system for your control application. |

| Integration | Medium | Evaluate how easily the servo drive integrates with existing systems. |

| Cost | High | Consider the cost versus performance to ensure you get value for your investment. |