-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

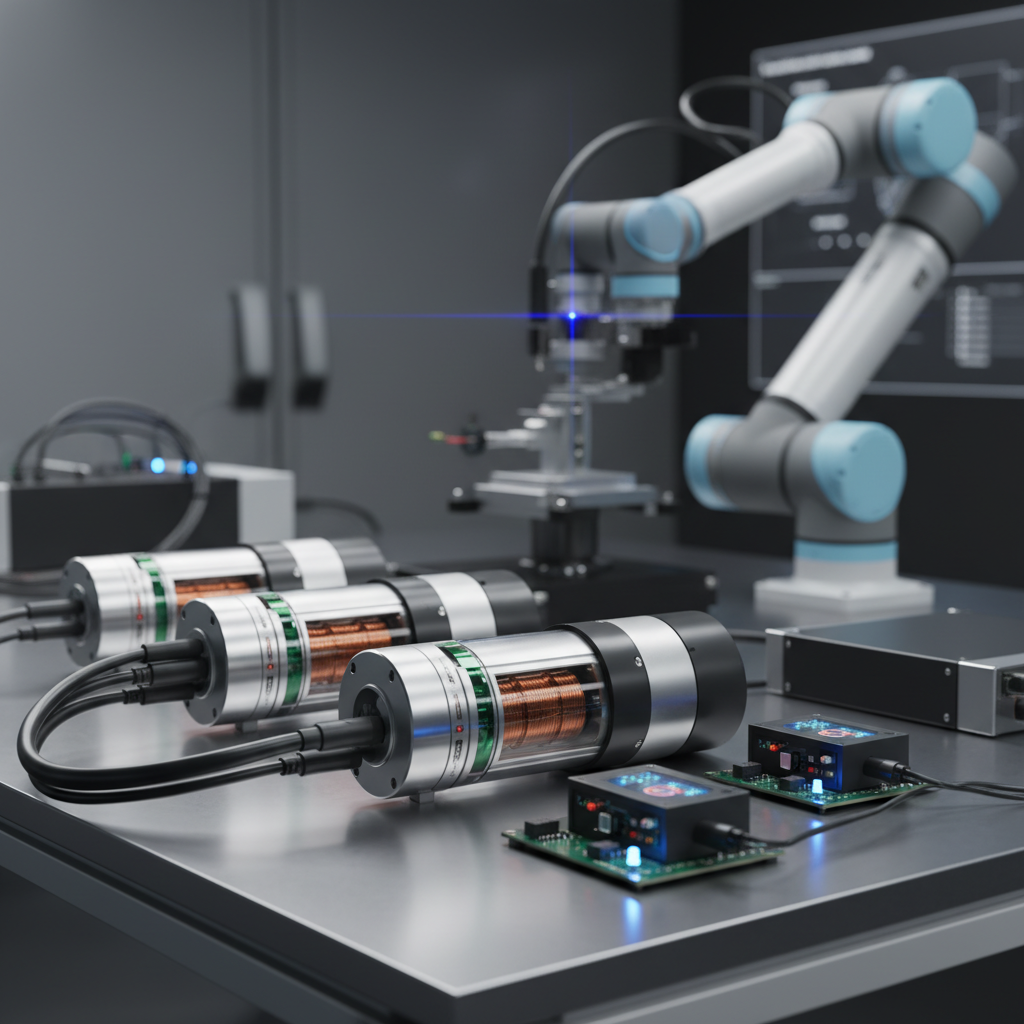

In the realm of precision engineering applications, the choice of motor technology plays a pivotal role in achieving optimal performance and accuracy. Among the various options available, Industrial Servo Motors stand out as a premier solution, known for their exceptional control characteristics and reliability. These motors are designed to meet the demanding requirements of high-performance machinery, enabling precise movement and positioning in a wide array of industries, including manufacturing, robotics, and aerospace.

Industrial Servo Motors are equipped with advanced feedback systems that allow for real-time monitoring and adjustment, ensuring that the machinery operates with the utmost precision. This capability not only enhances productivity but also minimizes the risk of errors, which is critical in applications where even minor deviations can lead to significant consequences. As the need for automation and efficiency grows in modern engineering, embracing Industrial Servo Motors becomes not just advantageous but essential for maintaining a competitive edge.

Furthermore, with the continuous advancements in technology, Industrial Servo Motors are becoming increasingly accessible and versatile, catering to a broad spectrum of applications. This introduction will delve deeper into the advantages of utilizing Industrial Servo Motors, exploring their features and the factors that make them an ideal choice for precision engineering tasks.

Industrial servo motors have become essential in precision engineering applications due to their exceptional performance and reliability. As industries continue to embrace automation and smart technologies, the benefits of servo motors are increasingly clear. For instance, the European servo motors and drives market is projected to reach USD 3.58 billion by 2031, driven largely by the demands of Industry 4.0 and energy efficiency initiatives. This growth reflects the pivotal role that high-precision motion control plays in modern manufacturing environments.

In precision positioning systems, servo motors deliver high levels of accuracy and repeatability, which are crucial for applications such as robotics and automated assembly lines. The introduction of advanced servo motor controllers, such as the latest 6-axis systems, enhances the ability to execute complex motion sequences with unparalleled precision. This technological advancement allows manufacturers to optimize processes, reduce waste, and improve product quality, underlining the vital importance of servo motors in modern engineering practices.

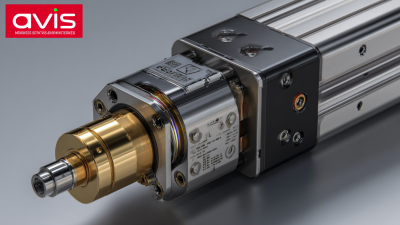

Industrial servo motors are pivotal in precision engineering applications, offering an array of key features that significantly enhance performance. One of the most notable characteristics is their closed-loop control system, which allows for real-time adjustments to motor position, speed, and torque. This capability ensures that the motor operates with exceptional accuracy, making it ideal for tasks that demand high precision, such as robotics and CNC machining.

Another crucial feature of servo motors is their high responsiveness and dynamic performance. With rapid acceleration and deceleration capabilities, these motors can adapt swiftly to changes in operational demands. This agility enables manufacturers to increase productivity and reduce cycle times in their processes. Additionally, servo motors often come with advanced feedback devices, such as encoders, which further enhance their accuracy and reliability. By integrating these technologies, industries can achieve superior results in precision engineering, ultimately driving improvements in quality and efficiency.

Servo motors are gaining traction in precision engineering industries due to their unparalleled accuracy and efficiency. In sectors such as robotics, aerospace, and automotive manufacturing, servo motors offer precise control over movement, which is crucial for intricate tasks. A report from the International Federation of Robotics indicates that the global robotics market is expected to grow at a CAGR of 26% through 2025, largely driven by advancements in servo motor technologies.

In applications like CNC machining and 3D printing, servo motors enable high-speed operations with minimal backlash. Data from Markets and Markets suggests that the precision machinery market is projected to reach $8.3 billion by 2026, with servo systems playing a pivotal role in this growth. These systems not only enhance production rates but also improve end-product quality, making them a preferred choice for manufacturers focused on precision engineering.

Tip: When selecting servo motors for your application, consider factors such as torque, speed, and feedback systems. These parameters significantly influence performance and efficiency, ensuring that the selected motor meets the specific needs of your engineering projects.

Another notable area where servo motors shine is in automation processes. Industries that rely on assembly lines are increasingly integrating servo technology to optimize cycle times and reduce operational costs. According to a study by Research and Markets, the automation market in manufacturing is projected to grow by $88 billion by 2025, with servo motors being a key component of this transformation.

Tip: Take into account the environmental conditions of your operational area. The right servo motor should withstand factors like temperature variations and dust exposure to ensure longevity and reliability in precision applications.

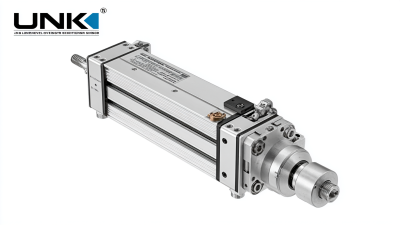

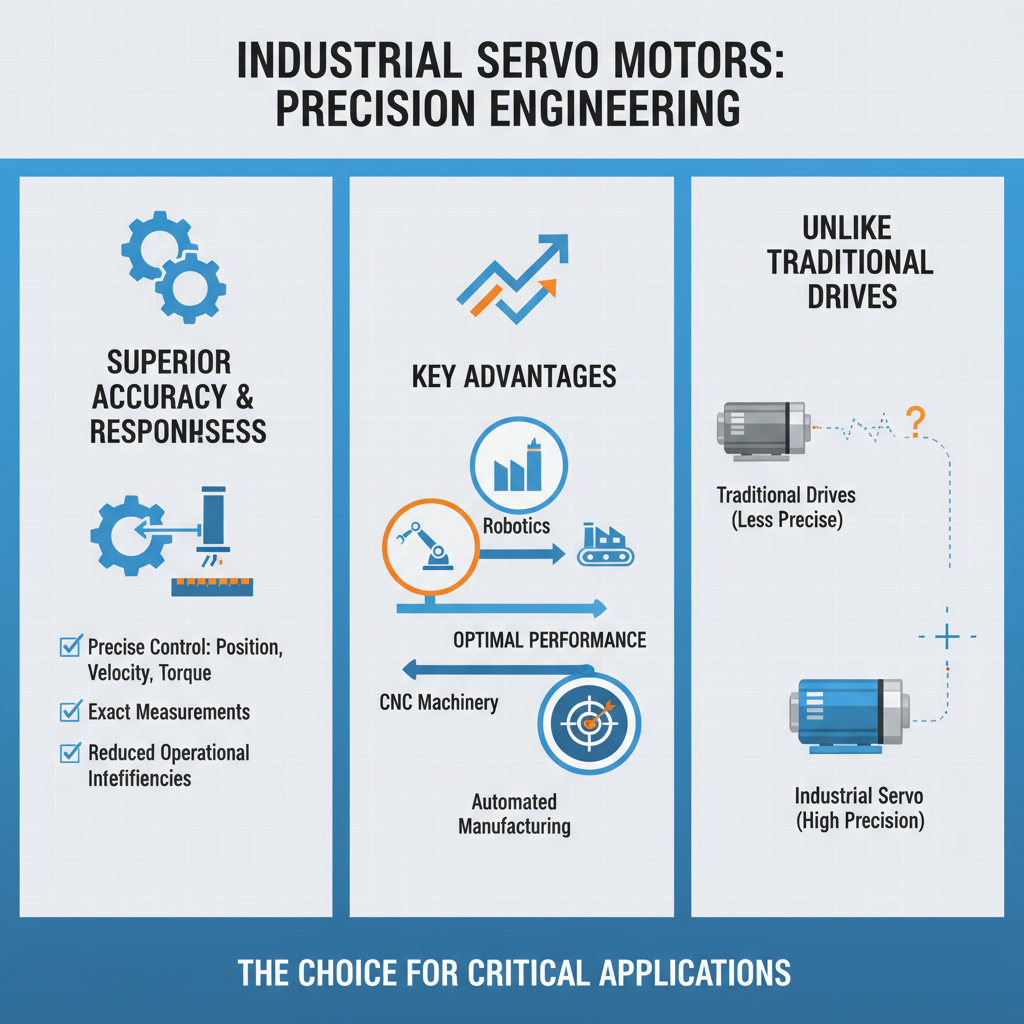

In the realm of precision engineering applications,

selecting the right drive system is crucial for achieving optimal performance. Among the various options available,

industrial servo motors stand out for their superior accuracy and responsiveness.

Unlike traditional drive systems, servo motors provide precise control over position, velocity, and torque, making them ideal for applications where exact measurements are necessary.

This precision is particularly beneficial in sectors like robotics,

CNC machinery, and automated manufacturing,

where even minor deviations can lead to significant operational inefficiencies.

When comparing servo motors to other drive systems such as stepper motors or DC motors,

several key differences arise. Stepper motors, while being low-cost and relatively simple, often lack the speed and torque capabilities that servo systems offer.

DC motors, on the other hand, require complex feedback mechanisms to achieve the same level of precision as servo motors, often resulting in increased system complexity and cost.

Thus, for applications demanding high-performance metrics and reliability,

industrial servo motors are increasingly becoming the preferred choice for engineers and designers aiming to push the boundaries of what is possible in precision-driven innovations.

When selecting servo motors for precision engineering applications, several factors must be taken into account to ensure optimal performance and reliability. One of the primary considerations is the torque requirement of your application. High precision applications often demand high torque at low speeds, so it's essential to choose a motor that can deliver the necessary performance without oversizing, which can lead to inefficiency.

Another critical factor is the feedback system used in the servo motor. Closed-loop systems with encoders generally provide higher accuracy than open-loop systems. Integrating a quality feedback mechanism allows for real-time monitoring of position, velocity, and torque, ultimately improving the system's performance.

**Tip:** Always evaluate the load characteristics and dynamic behavior of your application before making a selection. This will help determine the appropriate motor rating and type.

Additionally, consider the environmental factors such as temperature, humidity, and exposure to contaminants. Servo motors designed for industrial environments often have better insulation and sealing features.

**Tip:** Look for motors that comply with industry standards for durability, ensuring they can withstand the rigors of their operating environment.

| Criteria | Description | Importance Level |

|---|---|---|

| Torque | The ability to maintain torque under varying load conditions. | High |

| Speed | Response time and maximum speed capable of the motor. | High |

| Precision | The capability of the motor to accurately position and maintain positions. | High |

| Control Type | Open-loop or closed-loop control for desired feedback systems. | Medium |

| Mounting Size | Physical dimensions and compatibility with existing systems. | Medium |

| Environmental Considerations | Operating temperature, humidity resistance, and dust ingress protection. | High |

| Cost | Initial purchase price and total cost of ownership. | Medium |