-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

Choosing the right spindle motors for your CNC machines is a crucial decision that can significantly influence both the efficiency and quality of your machining processes. As the lifeblood of any CNC operation, spindle motors are responsible for the rotation and precision of tooling. According to Dr. Emily Carter, a leading expert in rotor dynamics and spindle technology, “Selecting the appropriate spindle motor is not just about power; it’s about achieving harmony between speed, torque, and application requirements.” Her insight emphasizes the complexity behind this seemingly straightforward choice.

Understanding the various factors that contribute to the performance of spindle motors can seem overwhelming. From calculating the required RPM to assessing thermal management and vibration, each aspect plays a vital role in optimizing your CNC setup. As industries strive for higher precision and efficiency, the right spindle motor can lead to better surface finishes, reduced cycle times, and increased overall productivity.

In this guide, we will explore key considerations when choosing spindle motors for your CNC machines, helping you navigate through specifications, types, and application needs to find the best fit for your operational goals. Ensuring that you make informed decisions in spindle motor selection can significantly elevate your machining capabilities and drive success in your manufacturing endeavors.

Spindle motors are essential components in CNC machines, providing the necessary rotating power needed for various machining tasks. Understanding the types and functions of spindle motors is critical for selecting the right one for your applications. Generally, spindle motors can be categorized into two main types: air-cooled and liquid-cooled. Air-cooled motors utilize a fan to dissipate heat, making them simpler and more cost-effective, while liquid-cooled motors are designed for more demanding applications that require higher power and consistent thermal management.

Another important aspect of spindle motors is their versatility in speed and torque. The speed of a spindle motor directly impacts the machining capabilities, allowing for different types of materials and finishes. High-speed spindle motors are ideal for precision tasks such as engraving, while those with greater torque are better suited for heavy cutting operations. Understanding the unique functions of each type of spindle motor helps operators tailor their equipment to achieve optimal performance and efficiency in their CNC machining processes. Selecting the right spindle motor not only enhances productivity but also prolongs the lifespan of the CNC machinery.

When selecting spindle motors for CNC machines, several critical factors must be taken into account to ensure optimal performance and efficiency. One of the primary considerations is the power requirements of the specific application. As reported by the Machinery Research Group, spindle motors typically operate within a range of 1.5 kW to 30 kW, with higher power outputs necessary for more demanding tasks such as high-speed milling or heavy machining. It's essential to match the motor power to the operational needs to prevent issues such as overheating or underperformance.

Another crucial factor is the motor speed and torque characteristics. Data from the International Society of Automation indicates that spindle motors can reach speeds exceeding 24,000 RPM, but the required speed will vary based on the material being machined and the desired finish quality. For instance, softer materials like aluminum may require different spindle capabilities compared to harder metals like titanium. Additionally, torque is vital; operators should assess the required torque values to maintain efficient cutting speeds without stalling the motor during operation, which can significantly affect production efficiency and tool lifespan.

Lastly, consideration of the spindle motor's build quality and cooling mechanisms is important to increase reliability and minimize downtime. High-quality motors often incorporate better thermal management solutions, such as liquid cooling, which can enhance performance during extended operations. According to a recent report by the CNC Industry Association, integrating advanced cooling technologies can extend spindle life by up to 50%, making it an essential factor in the selection process. By evaluating these factors judiciously, operators can significantly enhance their CNC machining efficiency and output quality.

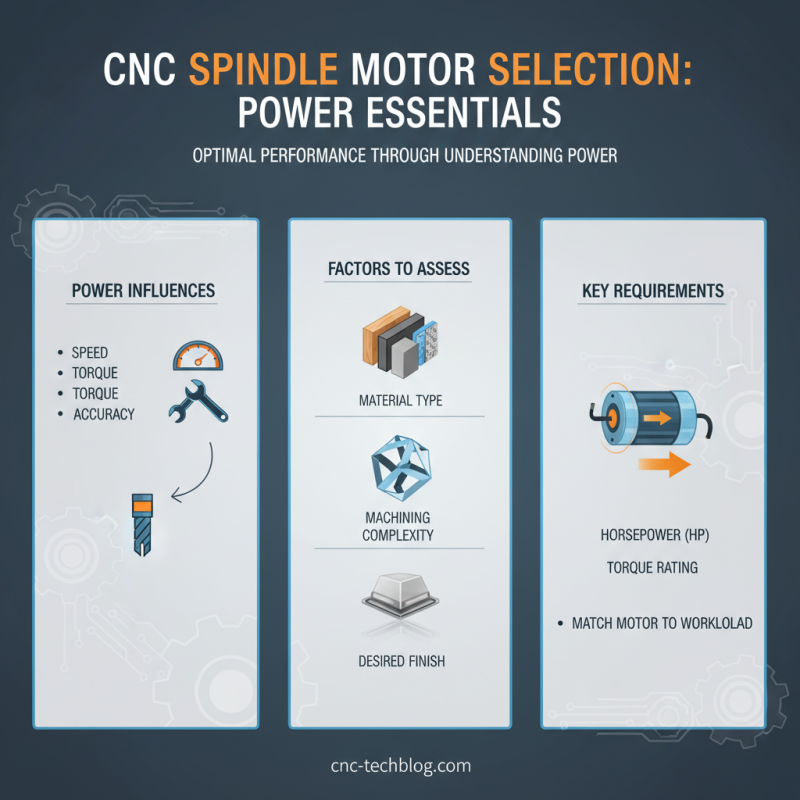

When selecting spindle motors for CNC applications, understanding power requirements is essential for achieving optimal performance. The power of a spindle motor directly influences the speed, torque, and accuracy of machining operations. Power requirements can vary based on the material being processed, the complexity of the machining task, and the desired finish. Therefore, assessing these factors will help determine the necessary horsepower and torque ratings for the spindle motor, ensuring it can handle the expected workload.

In addition to assessing general power needs, it's crucial to consider the specific dynamics of the CNC applications. Factors such as the type of cutting tools, the speed of operation, and the depth of cut can significantly impact the spindle's power requirements. A high-speed machining operation, for instance, may require a spindle motor with higher horsepower to maintain efficiency while preventing overheating and equipment wear. Consequently, conducting a thorough analysis of these parameters will aid in selecting a spindle motor that not only meets the power demands but also enhances the overall capabilities and longevity of the CNC machine.

When selecting spindle motors for CNC machines, ensuring compatibility with existing systems is crucial for optimal performance and efficiency. The first step in this process is to assess the specifications of your current CNC setup, including voltage, current ratings, and physical dimensions. Different machines may require specific spindle configurations, so a thorough understanding of your system's needs is essential.

Tips: Always refer to the CNC machine's manual for detailed specifications and any recommendations for spindle motor types that work best with your machinery. This can save you time and prevent potential compatibility issues.

Another important factor is the interface between the spindle motor and the CNC controller. Check if your controller supports the communication protocols that the new spindle motor uses. An incompatible interface can lead to difficulties in operation or even machine malfunctions.

Tips: Consider using flexible communication interfaces or opt for spindle motors that come with multiple connectivity options. This ensures that even if your CNC system evolves, your spindle motor will continue to function effectively.

Additionally, weight and mounting options of the new spindle motor should match the existing machine design to avoid any structural issues. Proper fitment is vital for maintaining balance during operation; any imbalance can lead to vibrations that affect precision and may damage the machine over time.

Tips: Always measure the mounting space and consult the specifications before making any purchase to ensure a proper fit.

When selecting spindle motors for CNC machines, the balance between cost and performance is critical. Initially, it may be tempting to opt for the most affordable options available, but this can lead to compromises in precision and reliability. A lower-cost motor might save money upfront, but it could result in higher maintenance costs, more frequent replacements, and overall lower productivity. Therefore, understanding the long-term implications of your investment is essential to ensure you’re not sacrificing quality for a lower price.

On the other hand, investing in higher-performance spindle motors often comes with a steeper price tag but can significantly enhance the capabilities of your CNC machines. These motors typically offer better speed control, increased torque, and higher precision, allowing for smoother operation and better machining results. Ultimately, assessing the specific requirements of your projects and weighing them against your budget will lead you to the right choice. An informed decision will not only meet immediate operational needs but also contribute to the machine's overall efficiency and longevity, resulting in a more satisfying return on investment in the long run.