-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

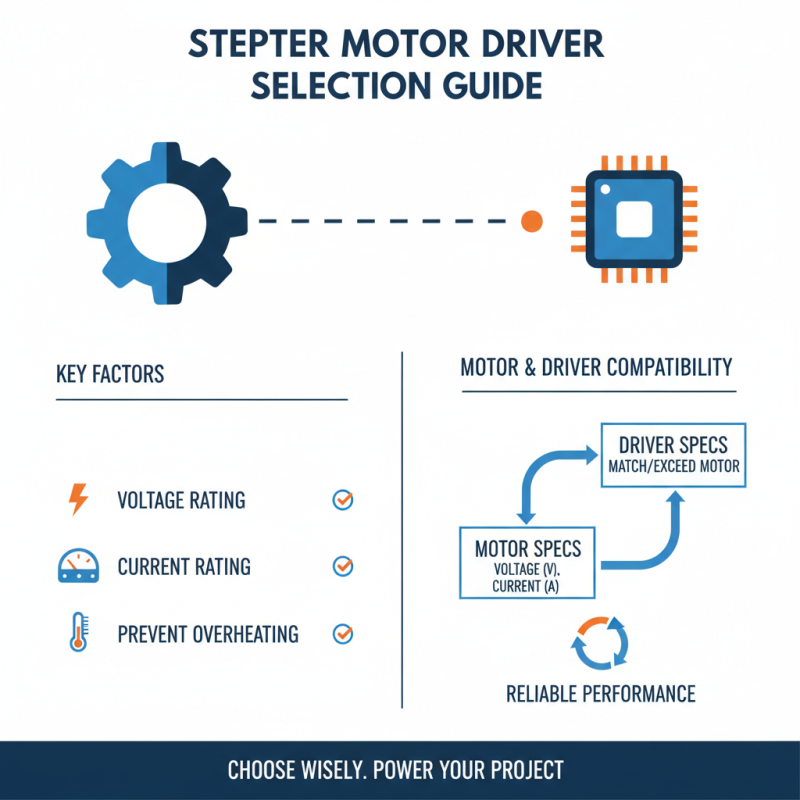

Choosing the right Stepper Motor Driver for your project is crucial. A suitable driver can significantly improve performance. This decision may seem straightforward, yet it can be quite complex.

Consider your project’s specific requirements. The voltage and current ratings of your stepper motor are key factors. Not all Stepper Motor Drivers suit every motor. Some drivers excel in precise control, while others focus on high torque. It’s essential to match these parameters correctly.

Another aspect to ponder is the ease of integration. Some drivers offer simple connections and clear documentation. Others may require advanced technical skills. Remember, the best choice isn't always the most popular one. Reflect on your needs before deciding. A mismatched driver can lead to frustration and poor results. Your choice impacts not just performance but also the long-term success of your project.

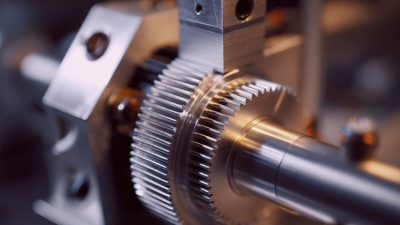

When working with stepper motors, it's essential to understand their drivers. A stepper motor converts electrical impulses into precise mechanical movement. It operates by using a series of electromagnetic coils that create magnetic fields. These fields interact with the rotor, allowing for controlled motion.

Choosing the right driver can sometimes be confusing. There are different types of drivers: bipolar and unipolar. Bipolar drivers allow for more torque, while unipolar ones are generally easier to use. You need to consider the power requirements of your motor. A mismatch can lead to overheating or underperformance.

Tips:

Understanding these fundamentals will aid in selecting the right driver. More knowledge equals better project outcomes. However, even experienced users can misjudge their needs. It's easy to assume more power is always better. This isn't always the case, so reflect on your specific application requirements.

Choosing the right stepper motor driver is crucial for any engineering project. It involves understanding your specific needs and the capabilities of various drivers. One key factor is the voltage and current ratings. Ensure the driver matches or exceeds the requirements of your stepper motor. This prevents overheating and ensures reliable performance.

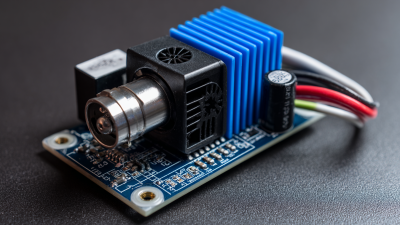

Compatibility is another important aspect. Make sure the driver you select can work seamlessly with your control system, be it Arduino or Raspberry Pi. Not all drivers are created equal; some may require additional components for proper operation.

**Tips:** Check the datasheet of your motor. It provides important specifications. Testing the driver with your motor can reveal potential issues. Always be ready to adapt your choices. Sometimes the ideal driver may not be the most expensive or feature-rich one.

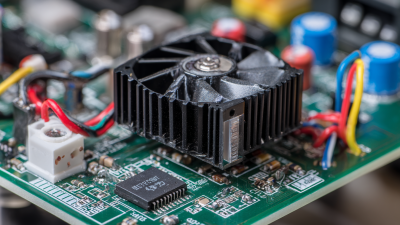

Keep in mind that heat management is often overlooked. Inadequate cooling can lead to reduced performance or failure. Look for drivers with built-in thermal protection features. Such options can save you from future headaches.

Lastly, consider the step resolution needed for your application. Different drivers offer different microstepping capabilities. Choose a driver that provides the resolution your project demands. It can greatly affect the smoothness and accuracy of motor movement.

Choosing the right stepper motor driver requires understanding the various types available. Generally, there are two main categories: L/R (Linear/Resistor) drivers and chopper drivers. L/R drivers are simpler and cheaper but less efficient. They can generate overheating issues during operation. Chopper drivers, on the other hand, use pulse-width modulation to control motor power. This can lead to smoother performance and higher speed capabilities, but they may introduce complexity in control.

Applications of these drivers vary significantly. For example, L/R drivers are often found in basic 3D printers and CNC machines. They serve simple functions without high-speed demands. Chopper drivers, by contrast, suit robotics and advanced automation systems. Here, precision and torque are critical. However, it’s essential to consider noise levels as chopper drivers can create humming sounds during operation.

Selecting the right driver isn't easy. Misjudging your project needs might lead to inefficient performance. Identifying your motor's voltage and current specifications is crucial. Testing different drivers might also reveal better options. Even experienced engineers can overlook factors like thermal management and power supply stability. Every project has unique challenges, and thus, no one-size-fits-all solution exists.

| Driver Type | Microstepping Resolution | Max Current (A) | Applications |

|---|---|---|---|

| L298N | Full Step, Half Step | 2.5 | Robotics, CNC Machines |

| A4988 | Full Step, Half Step, 1/4, 1/8, 1/16 | 2.0 | 3D Printers, Robotics |

| DRV8825 | Full Step, Half Step, 1/4, 1/8, 1/16, 1/32 | 2.5 | 3D Printing, CNC |

| TMC2208 | Full Step, 1/16, 1/32 | 2.0 | Silent Stepper Control, 3D Printing |

| TB6600 | Full Step, Half Step, 1/4, 1/8 | 4.0 | CNC Routers, Laser Engraving |

When selecting a stepper motor driver, it's crucial to align its specifications with your project's needs. Consider the motor type you are using. Different motors require varying levels of voltage and current. For instance, a high-torque motor will necessitate a driver that can handle higher currents. Insufficient current might lead to poor performance or stalling.

Tips: Always check the driver’s current rating against your motor’s specifications. A mismatch could impact your project’s efficiency.

Another important factor is the control method. Many stepper drivers utilize different signals for operation. Some use pulse width modulation, while others may work with analog inputs. Understanding these methods can determine how well your driver integrates with your existing systems.

Tips: Experiment with control signals during testing. This phase can reveal unanticipated issues that need addressing.

Temperature management is also essential. Stepper motors can overheat if the driver doesn’t support thermal protection. A driver with good thermal dissipation features is often necessary. Ignoring this might lead to failure in critical situations.

Tips: Monitor your driver’s temperature in real-time. If it overheats, adjust your design before proceeding further.

Stepper motors are popular in various applications, but issues with drivers can arise. Understanding these common problems is essential for successful projects. Overheating is a frequent concern. According to industry reports, 30% of stepped motor failures are due to inadequate cooling. If a driver overheats, it may enter thermal shutdown. Ensure that your driver has proper heat sinks and ventilation.

Another common issue is missed steps. This can stem from insufficient current supply. About 25% of users report this problem. It often leads to inaccurate positioning. Users should carefully calculate the current requirements based on motor specifications. Fine-tuning settings may also be necessary. Sometimes, a driver may lag due to incorrect pulse input frequency. Testing with different frequencies can help resolve this.

Lastly, electrical noise can affect driver performance. In fact, around 15% of failures occur due to electromagnetic interference. Shielding cables and using twisted pairs can mitigate this issue. Regularly inspect connections to avoid loose wiring. A few simple preventive measures can make a significant difference in ensuring reliable operation.

This chart illustrates the performance metrics of different stepper motor drivers based on two key parameters: Current Rating (in Amperes) and Maximum Step Frequency (in Hz).