-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

Choosing the right stepper motors for your projects can significantly impact performance. In recent years, the stepper motor market has seen a rapid growth, with a projected increase of 4.5% annually through 2026. This growth highlights the importance of understanding your requirements before selection.

Stepper motors offer precision in motion control, making them popular in robotics and automation. However, not all stepper motors are made equal. Factors such as torque, size, and type can affect project outcomes. A mismatch can lead to underperformance or efficiency losses, which is not ideal.

Additionally, specialized applications may demand specific features that standard models do not provide. Reflecting on your project's needs is crucial, as it can help prevent costly mistakes. Engaging with reliable data sources and expert recommendations will aid in making informed decisions. Stepper motors are versatile, yet their selection should be approached with care.

Stepper motors are essential in many applications, from 3D printers to robotics and CNC machines. Understanding the various types of stepper motors helps in selecting the right one for your project. There are two common types: permanent magnet (PM) and hybrid stepper motors. PM motors are simpler and often cost-effective, with low torque ratings. In contrast, hybrid motors combine characteristics of PM and reluctance motors, providing better performance and precision.

A report from Research and Markets indicates that the global stepper motor market is expected to grow at a CAGR of 5.2% from 2021 to 2026. This growth reflects increased demand in industrial automation and consumer electronics. Many projects require specific torque and speed specifications. For instance, a low-torque stepper might struggle in a heavy-load application. Proper selection is crucial; a mismatch could lead to project failures.

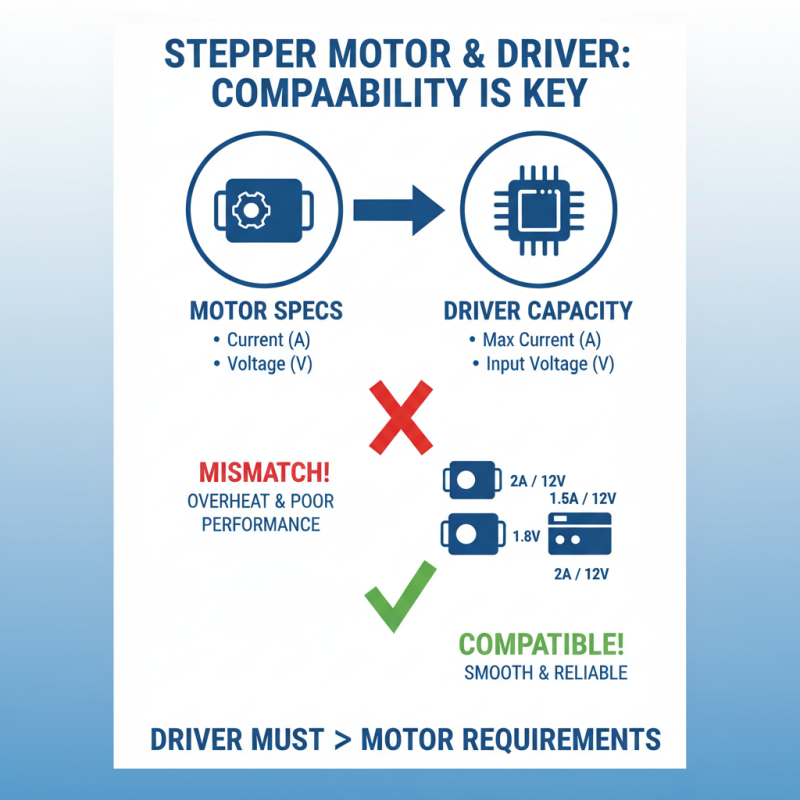

When choosing a stepper motor, consider the driver type. It controls the motor's operation and affects performance. Many users overlook this aspect. A poorly matched driver can lead to overheating and reduced efficiency. Connecting the right driver ensures optimal performance. Remember, each stepper motor comes with unique specifications, ensuring it fits its intended application well.

When selecting stepper motors for a project, several key specifications are essential. Begin with torque ratings. This determines the motor’s lifting capability. Higher torque is crucial for heavier loads. Still, balance is important; excessive torque can lead to oversizing. This affects performance in tight spaces.

Next, consider step angle. A smaller step angle yields higher resolution, crucial for precision tasks. However, high-resolution motors may be more complex to control. It’s essential to find a balance between precision and software complexity.

Another critical factor is current rating. Motors draw different current levels based on load. Too much current can cause overheating. Conversely, insufficient current may lead to inadequate performance. Pay attention to power supply needs. It’s vital to ensure compatibility with your overall system. In many cases, users overlook integration challenges, resulting in subpar performance. Understanding these details can greatly influence project success.

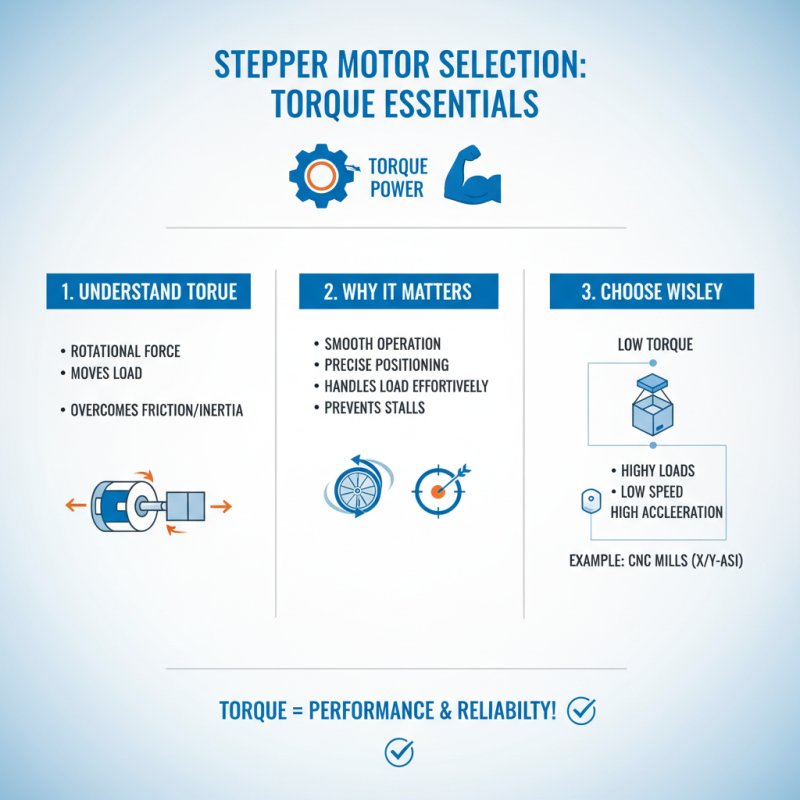

This chart compares various stepper motors based on critical specifications such as holding torque and step angle. It helps in visualizing the performance metrics essential for selecting the right motor for your project.

Choosing the right stepper motor involves understanding torque requirements. Torque is essential for performance. It defines how much load your motor can handle effectively. This is crucial for ensuring your project operates smoothly.

To determine the proper torque, consider your application's demands. Evaluate the weight of the load. Assess how quickly it needs to move. The rotational speed also plays a role. Calculate these factors. Sometimes, you might underestimate the torque needed. This can lead to motor failure or stalling. Testing various scenarios can help refine your torque calculations.

When in doubt, choose a motor with slightly more torque than you think you need. It’s better to have excess capacity than to run at the limit. However, overestimating can lead to unnecessary costs. Balancing cost and performance is tricky. Taking time to reflect on your project requirements is vital. Adjustments may be necessary as your project evolves. Be prepared to make those changes.

When selecting stepper motors, driver compatibility is crucial. It’s not just about the motor's specifications. You need to ensure that the driver can handle the motor's current and voltage requirements. Different motors have unique characteristics. For example, a motor rated at 2A might not work well with a driver rated for only 1.5A. This mismatch can lead to overheating and performance issues.

Consider the control type as well. Some motors require specific drivers for advanced features like microstepping. If your project plans rely on smooth operation, you don't want to overlook this aspect. It’s often a mistake to focus solely on the motor without considering the driver. Incompatibility can blindside even experienced engineers, leading to frustrating trial and error phases.

Additionally, it's important to double-check wiring configurations. Simple mistakes in connections can cause major headaches. If the motor’s wiring does not match the driver’s outputs, it can lead to malfunctions. Attention to detail is essential here. Tuning your setup may also take time, and you might not get it right on the first try. Be prepared for some back-and-forth adjustments.

Choosing the right stepper motors can significantly impact your project's success. Evaluating cost versus performance is crucial. A high-performing stepper motor might offer better precision and torque, yet it may strain your budget. A recent industry report indicates that investing in quality motors can lead to a 15-20% increase in system efficiency.

Budget constraints often force engineers to compromise on performance. Sometimes, cheaper motors lead to overheating or loss of steps. That's a costly mistake. Consider the long-term effects of your initial investment. The right motor can reduce maintenance costs and enhance durability. An analysis showed that projects using high-quality stepper motors had a 30% lower failure rate.

Tip: Assess your project’s requirements before purchasing. Match torque needs with the motor's specifications. Ensure that your choice aligns with the performance expectations. Another tip: collect feedback from users in similar projects. Their experiences can provide insights into practical performance versus advertised capabilities. Prioritize reliability over initial cost whenever possible.