-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

Choosing the right Servo Drives is crucial for your project’s success. These devices play a key role in controlling motors and precise movements. Without the right selection, your entire project could face performance issues. Different applications require different Servo Drives, making the choice complex.

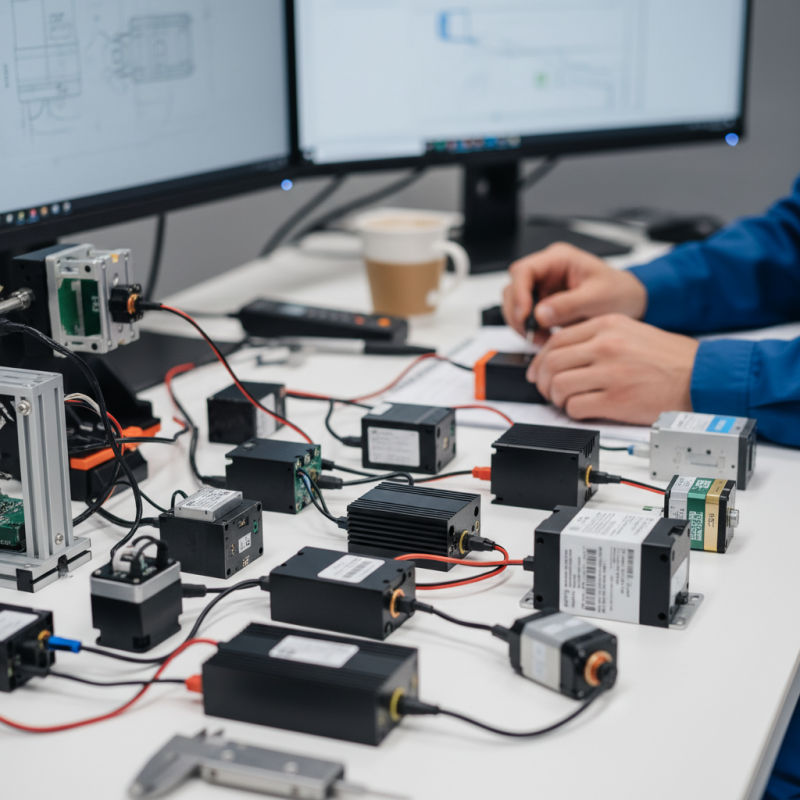

Understanding your project’s specific needs is vital. Consider factors such as power requirements, load characteristics, and response time. Many projects fail because the team overlooks these details. For instance, selecting a drive with inadequate torque can lead to severe operational problems. There’s no one-size-fits-all solution when it comes to Servo Drives.

Evaluating available options is essential. Some drives may promise great performance but don’t deliver in real-world conditions. Choose wisely. Test different Drive types. Gather feedback throughout the process. Balancing features and cost is challenging. It can feel overwhelming at times. Reflect on your choices to ensure they meet your project’s unique demands.

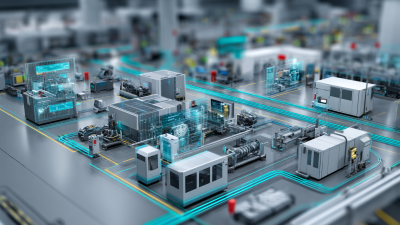

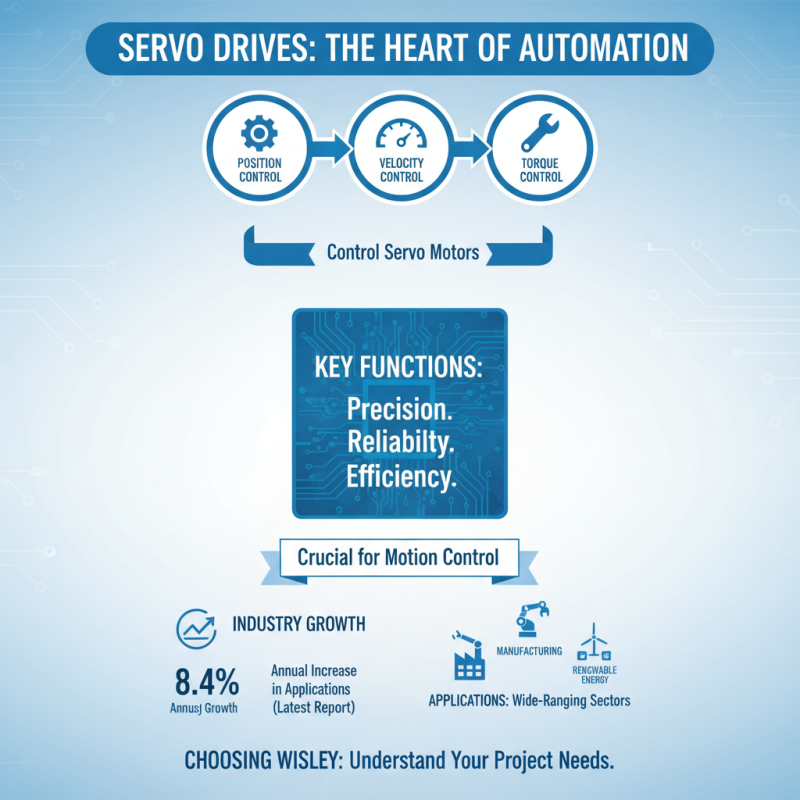

Servo drives play a crucial role in automation and motion control. They control the position, velocity, and torque of servo motors. Understanding their fundamental functions is key to making the right choice for your project. According to the latest industry report, servo drive applications have seen a growth of 8.4% annually. This indicates a strong demand for precision in control systems across multiple sectors.

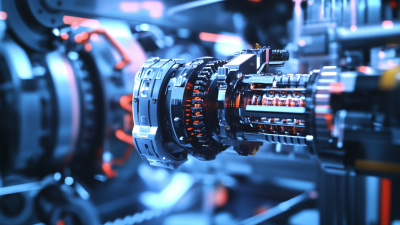

When assessing servo drives, consider the type of feedback they utilize. There are open-loop and closed-loop systems. Closed-loop systems often provide better accuracy and responsiveness. They receive constant feedback from the motor, allowing for real-time adjustments. This feedback mechanism is essential in applications requiring high precision. The selection process can be complex, which sometimes leads to confusion.

Another important aspect is the compatibility of the servo drive with its motor. A mismatch can lead to inefficiencies. For example, pairing a low-torque motor with a high-power drive can result in wasted energy and decreased performance. Addressing these compatibility issues is vital, yet some engineers overlook them, leading to potential project setbacks. Workers should critically evaluate their choices. Balancing performance with the specific needs of your application is essential for success.

Selecting the right servo drives begins with understanding your project's specific requirements. Factors like load type, speed, and precision are essential to consider. For example, a study by the International Society of Automation highlights that 70% of automation failures stem from mismatched drive parameters. Knowing these measurements helps prevent error-prone configurations.

Precision is paramount in applications like robotics or CNC machines. A recent report from the Robotics Industry Association indicated that 30% of failed robotic deployments were due to inadequate servo drive specifications. Projects demanding high accuracy often require drives with advanced feedback mechanisms. However, many engineers overlook this when focusing on cost.

Speed is another critical element. Different projects require varying rates of response and positioning. If your drive isn’t swift enough, it will slow down your operations. A survey revealed that 40% of manufacturers faced productivity losses from improperly chosen servo systems. Evaluating the timeline of your tasks can help gauge these needs accurately. Each project has unique traits. Therefore, reflecting on these details can lead to improved outcomes.

| Requirement Dimension | Description | Recommended Range |

|---|---|---|

| Torque | The amount of rotational force needed for your application. | 0.5 Nm - 10 Nm |

| Speed | The operational speed necessary for your project. | 1000 rpm - 6000 rpm |

| Feedback Type | Type of feedback used for positioning control. | Incremental, Absolute |

| Power Supply | Voltage requirements for operating the servo drive. | 24V - 220V |

| Control Mode | How the drive receives commands (e.g., PWM, analog). | Position, Speed, Torque |

| Environmental Conditions | Temperature and humidity range for operation. | -20°C to 60°C |

Choosing the right servo drives involves careful evaluation of the types available. Servo drives are crucial in automation. They control motors for precision tasks. The market for these drives is expected to grow significantly. Reports suggest a CAGR of over 7% in the coming years. This growth signals rising demand for efficiency and precision in various industries.

Different types of servo drives serve varying tasks. There are AC, DC, and stepper drives. AC servo drives are common in robotics. They offer high efficiency and torque. DC drives have simpler designs. They are often less expensive but may lack the same precision. Stepper drives are ideal for applications needing precise positioning. They can be less effective under load.

Tip: Assess your project's specific needs before selecting a drive. Consider the operational environment, required accuracy, and load conditions. It's easy to overlook these details, yet they are vital for performance. Remember, not every drive suits every project. Testing different options can yield better results. Customer feedback can also provide insight. Engaging with user experiences may highlight potential concerns.

When selecting servo drives, compatibility is paramount. Evaluate the current system’s voltage, current ratings, and communication protocols. A study by the International Society of Automation indicates that nearly 40% of drive failures stem from compatibility issues. This underscores the need for thorough checks before purchasing.

Consider your existing motor specifications. Mismatched drive parameters can lead to inefficiencies. For instance, if the drive cannot support the motor’s requirements, it may overheat or underperform. A 2020 report from the Electric Drives and Controls Association found that systems operating outside of their specifications exhibit a 25% decrease in lifecycle performance.

It’s also crucial to check integration capabilities with your current automation system. A lack of interoperability can cause increased downtime. Minor adjustments on the software side can sometimes alleviate these hurdles, but these solutions may not always be feasible. Incompatibilities often lead to unforeseen costs, both in repairs and lost productivity. Awareness of these nuances can guide a more informed decision-making process.

When choosing servo drives, balancing cost and performance is crucial. Many projects require precision in motion control, but high-quality servo drives can be expensive. It's essential to assess the specific needs of your project. Higher performance can come with a price. But is that extra functionality necessary? Sometimes, basic features suffice.

Tips: Consider the size and weight of your applications. Does your project demand compact solutions? Costly drives may not always serve your needs. Look for alternatives that provide adequate performance without compromising budget constraints.

Additionally, explore efficiency ratings. Drives with better energy efficiency may save costs long-term, even if initial prices are higher. Reflect on whether the cost aligns with your project goals. It's a balancing act, and time spent on research pays off. Don't rush into a decision.