-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In today's fast-paced technological landscape, selecting the right Servo Motors for your applications can significantly impact the performance and efficiency of your systems.

Servo Motors are essential components in various industries, from robotics to aerospace, where precision and reliability are paramount.

With the myriad of options available, it's crucial to understand the different types of Servo Motors, their functionalities, and the specific requirements of your application.

This ultimate guide will delve into key considerations, providing you with actionable reasons for choosing the most suitable Servo Motors that align with your project’s demands.

Whether you're looking for high torque, speed, or precision, making informed decisions will ensure that your applications are optimized for success.

Servo Motors are essential components in various industries, from robotics to aerospace, where precision and reliability are paramount.

With the myriad of options available, it's crucial to understand the different types of Servo Motors, their functionalities, and the specific requirements of your application.

This ultimate guide will delve into key considerations, providing you with actionable reasons for choosing the most suitable Servo Motors that align with your project’s demands.

Whether you're looking for high torque, speed, or precision, making informed decisions will ensure that your applications are optimized for success.

When it comes to choosing the right servo motor for your applications, understanding the different types available is crucial. Servo motors can generally be categorized into three main types: DC, AC, and stepper motors.

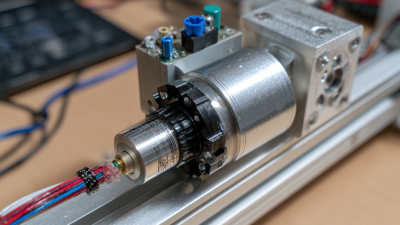

DC servo motors are known for their simplicity and ease of control, making them ideal for applications requiring precise movement and speed control. They operate on direct current and are widely used in robotics and automated systems. The performance of DC servo motors can significantly improve with feedback mechanisms, allowing for enhanced accuracy and responsiveness.

DC servo motors are known for their simplicity and ease of control, making them ideal for applications requiring precise movement and speed control. They operate on direct current and are widely used in robotics and automated systems. The performance of DC servo motors can significantly improve with feedback mechanisms, allowing for enhanced accuracy and responsiveness.

AC servo motors, on the other hand, are favored for their robustness and high efficiency. They utilize alternating current and are often found in applications demanding high torque and speed stability. With their ability to maintain precise position control over a wide range of speeds, AC servo motors are common in industrial machinery and CNC systems. Lastly, stepper motors provide precise position control without the need for a feedback system. They are particularly suited for applications where accuracy and repeatability are critical, such as 3D printers and CNC milling machines.

By understanding the strengths and weaknesses of each type of servo motor, you can make informed decisions tailored to your specific application needs.

When it comes to high-precision applications, DC servo motors stand out due to their exceptional control and performance capabilities. According to a report by MarketsandMarkets, the global DC servo motors market is projected to reach $3.5 billion by 2025, driven by increasing demand in sectors such as robotics, automation, and medical devices. These motors provide precise speed and position control, which are critical for applications like CNC machinery and advanced robotics. With a feedback loop incorporating encoders, DC servo motors can continuously adjust their operations to achieve a desired output with minimal error.

Moreover, the efficiency of DC servo motors is another significant advantage in high-precision applications. A study from the International Journal of Electrical Engineering & Technology highlights that these motors can achieve efficiency levels of up to 95%. This high efficiency translates to lower energy consumption and reduced operational costs, making them an attractive choice for manufacturers looking to optimize performance while minimizing expenditures. As industries increasingly focus on automation and precision manufacturing, the role of DC servo motors is set to become even more vital, paving the way for innovations and advancements in technology.

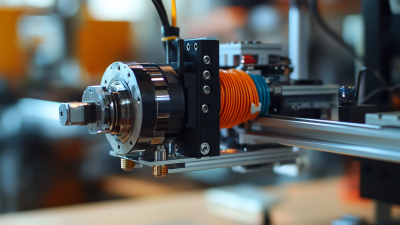

When it comes to selecting the right servo motor for your applications, understanding the differences between AC and DC servo motors is essential. AC servo motors are increasingly favored in industrial automation due to their superior performance in high-speed applications and their ability to deliver consistent torque. They are particularly effective in environments that demand high precision and reliability, making them ideal for advanced manufacturing processes that seek to minimize human error.

On the other hand, DC servo motors offer simplicity and ease of control, which can be advantageous in applications that do not require the high-speed capabilities of AC motors. They generally come with a lower initial cost and can be easier to integrate into simpler systems. However, the ongoing shift toward automation in various vertical industries suggests a rising trend in the adoption of AC motors. With increasing demands for production efficiency and accuracy, choosing the right type of servo motor is critical to enhance your operational capabilities and meet market expectations effectively.

Choosing the right servo motor is crucial for optimizing performance in robotics applications. Servo motors provide precise control over angular position, velocity, and acceleration, making them ideal for various robotic functionalities such as articulation, end effector movement, and navigation. When selecting a servo motor, it’s essential to consider factors such as torque requirements, speed, and the overall load conditions of your robotic system. Higher torque motors are typically required for heavy-duty applications, while lightweight robots may benefit from smaller, more energy-efficient models.

Additionally, understanding the types of control systems compatible with your servo motor can significantly impact performance. For example, choosing between analog and digital servo motors can influence responsiveness and accuracy. Digital servos generally offer better precision and faster reaction times due to their advanced feedback systems. Furthermore, it's important to factor in the operating environment, as certain motors are better suited for conditions that require resistance to dust, moisture, or extreme temperatures. By aligning your selection with these parameters, you can ensure optimal performance and longevity for your robotic project.

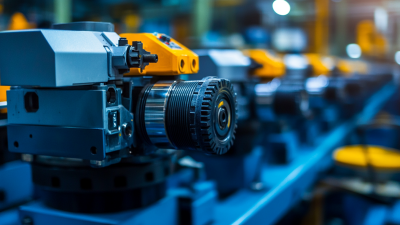

| Motor Type | Torque (Nm) | Speed (RPM) | Voltage (V) | Application |

|---|---|---|---|---|

| AC Servo Motor | 5.0 | 3000 | 220 | Industrial Automation |

| DC Servo Motor | 7.5 | 2000 | 24 | Robotics |

| Stepper Motor | 1.2 | 600 | 12 | 3D Printing |

| Servo Motor with Gearbox | 15.0 | 1500 | 48 | CNC Machines |

| Brushless DC Servo Motor | 10.0 | 6000 | 36 | Robotic Arms |

Choosing the right servo motors is crucial for ensuring cost-effectiveness in industrial automation. The selection process goes beyond merely opting for a motor that meets the basic specifications; it involves understanding the total lifecycle costs associated with the machine. A properly matched servo motor can optimize performance, reduce energy consumption, and extend the lifespan of the equipment, leading to significant savings over time.

Investing in high-quality servo motors designed for specific applications can drastically reduce maintenance costs and downtime. For instance, using motors that are precisely tailored to the load requirements can mitigate wear and tear on both the motor and connected machinery. Furthermore, the efficiency of a well-chosen servo motor can also enhance productivity, allowing manufacturers to increase output without corresponding rises in operational costs. This creates a sustainable economic model in the long run, making the initial investment in the right motor a smart financial decision.

This chart illustrates the cost-effectiveness comparison among different types of servo motors used in industrial automation applications, highlighting their initial costs and average lifespan.