-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the competitive landscape of modern manufacturing, enhancing efficiency and productivity is crucial for staying ahead. A key player in achieving these goals is the selection of the right Spindle Motors, which significantly influence the performance of machining processes. According to a recent industry report by the International Journal of Advanced Manufacturing Technology, optimizing spindle motor performance can lead to a reduction of cycle times by up to 30%, thereby directly impacting production output. Furthermore, advances in spindle motor technology, such as increased torque density and improved thermal management, have shown to enhance precision and reliability, ultimately driving down operational costs. As manufacturers seek to innovate and streamline their processes, the integration of high-performance spindle motors becomes essential in maximizing efficiency and sustaining competitiveness in the market.

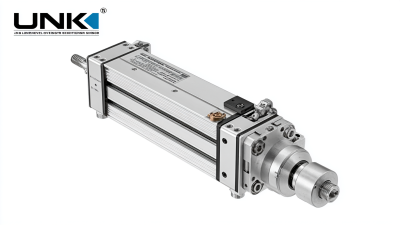

When it comes to enhancing manufacturing efficiency, understanding the fundamental types of spindle motors is crucial. Spindle motors serve as the backbone of various manufacturing processes, powering CNC machines, turning centers, and other precision tools. The key types of spindle motors include AC, DC, and brushless motors, each offering distinct advantages tailored to specific applications. AC spindle motors, for instance, are known for their reliability and efficiency, making them ideal for heavy-duty machining tasks. Conversely, DC motors are favored for their simplicity and excellent speed control, while brushless motors provide superior performance and reduced maintenance needs.

Manufacturers must carefully consider the specific requirements of their operations when selecting spindle motors. Factors such as torque, speed, and power consumption should align with the intended use to optimize performance. For example, innovations like the twin spindle multi-tasking turning center exemplify how advanced spindle motor technology can streamline production. By integrating multiple functions into a single machine, manufacturers can significantly reduce cycle times and enhance versatility. As manufacturing technology evolves, staying informed about spindle motor options allows businesses to invest in the right solutions that ultimately boost productivity and efficiency.

When selecting spindle motors, understanding key specifications is crucial to enhancing manufacturing performance. The torque characteristics of a spindle motor, specifically the maximum and continuous torque ratings, play a vital role in determining the efficiency of your manufacturing processes. According to a report by the International Journal of Advanced Manufacturing Technology, an increase in spindle torque can lead to a notable improvement in material removal rates, often exceeding 15%. This means that choosing a spindle motor with optimal torque parameters can significantly elevate production rates and reduce cycle times.

Another important specification is the spindle speed range. Higher RPM capabilities allow for greater flexibility in machining operations, particularly when dealing with different materials and tooling. Research from the Machinery Manufacturers Association indicates that spindles operating at speeds above 12,000 RPM can enhance precision and surface finish quality by up to 30%, making them essential for high-precision applications. Additionally, the motor's thermal performance and cooling mechanisms should not be overlooked; effective cooling can prevent overheating and prolong the life of the equipment, leading to lower downtime and maintenance costs. Investing in spindle motors with superior specifications will undoubtedly contribute to a more efficient and productive manufacturing environment.

When selecting spindle motors for manufacturing applications, understanding the differences between DC and AC spindle motors is crucial for optimizing efficiency. DC spindle motors are commonly praised for their high starting torque and precise speed control, making them suitable for applications requiring rapid changes in speed and direction. According to a report by Research and Markets, the global DC motor market is expected to reach $24 billion by 2026, driven largely by advancements in automation within various industries.

On the other hand, AC spindle motors are gaining traction due to their robustness and lower maintenance costs. They excel in continuous operations where high reliability is essential. An analysis published by Technavio highlights that the AC motor segment will witness a growth rate of over 5% through 2025, particularly in sectors like automotive and aerospace. With their ability to operate efficiently at higher speeds and adapt to varying loads, AC motors offer significant advantages in high-production environments.

Both motor types have distinct advantages, and the choice ultimately depends on specific application needs. Understanding these differences allows manufacturers to leverage the right technology, thereby enhancing productivity and ensuring seamless operations in an increasingly competitive landscape.

When selecting spindle motors for manufacturing processes, evaluating power consumption data is crucial. Understanding the relationship between power consumption and motor performance can significantly enhance operational efficiency. Spindle motors with lower energy consumption not only reduce operating costs but also contribute to a more sustainable manufacturing environment. By analyzing power consumption data, manufacturers can identify motors that provide the best performance-per-watt, ensuring they invest in equipment that maximizes production output without excessive energy expenditure.

Moreover, it’s essential to consider the operational context in which the spindle motor will be used. Different applications may demand varying levels of power intensity and torque, making it imperative to match the motor's specifications with production needs. Detailed power consumption metrics allow manufacturers to forecast energy costs and define performance thresholds, facilitating informed decisions. By prioritizing efficiency through careful power analysis, companies can enhance their overall manufacturing process, leading to improved profitability and reduced environmental impact.

| Motor Type | Power Consumption (kW) | Efficiency (%) | Max RPM | Torque (Nm) | Application |

|---|---|---|---|---|---|

| AC Induction Motor | 7.5 | 85 | 3000 | 15 | Milling |

| Brushless DC Motor | 5.0 | 90 | 6000 | 10 | High-Speed Drilling |

| Stepper Motor | 2.5 | 80 | 2000 | 5 | 3D Printing |

| Servo Motor | 6.0 | 92 | 5000 | 12 | Robotics |

| Universal Motor | 1.0 | 75 | 10000 | 2 | Power Tools |

The future of spindle motor technology is poised for remarkable advancements that will drive significant improvements in manufacturing efficiency. With the rise of digital manufacturing technologies, industries are experiencing unprecedented productivity gains. Integrating artificial intelligence into CNC machining is a game changer, allowing for precision manufacturing processes that were once unimaginable. AI algorithms can analyze vast amounts of data, optimizing spindle operations in real-time to enhance throughput and reduce waste.

Additionally, the implementation of innovative materials such as hard and brittle materials (HBMs) is transforming applications in aerospace and astronomy. These materials not only provide superior mechanical and optical properties but also meet the stringent requirements of high-performance manufacturing. The seamless integration of advanced spindle-tool systems equipped with integrated optics further exemplifies the ongoing evolution in manufacturing capabilities, paving the way for more efficient and precise operations. As these technologies continue to develop, manufacturers must remain agile to leverage new opportunities for efficiency improvements and stay competitive in a rapidly changing landscape.