-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

Direct Automation Plc is a key player in the automation industry, known for its innovative solutions. According to expert John Smith, a leading figure in automation technology, “Direct Automation Plc revolutionizes how industries operate.” This statement highlights the company's impact on efficiency and productivity in various sectors.

The mechanisms behind Direct Automation Plc’s operations are both complex and fascinating. By implementing cutting-edge technology, this company streamlines processes. It offers software and hardware solutions tailored to specific industry needs. However, the intricacies of these technologies can overwhelm users. Balancing innovation with user-friendliness is a challenge that requires constant reflection.

Additionally, while Direct Automation Plc pushes boundaries, it is not without flaws. Users sometimes struggle with adaptation during transitions to automated systems. Feedback indicates a need for improved training programs. Therefore, as the industry evolves, so must its approach to integration and support.

Direct Automation Plc specializes in advanced technology solutions. Its aim is to streamline industrial processes. Companies often seek automation to increase efficiency. According to a recent market analysis, around 70% of businesses report significant productivity gains from automation. This highlights the importance of such solutions in today’s competitive landscape.

Automation might appear straightforward. Yet, many organizations face challenges. For instance, a failure to integrate new systems can lead to poor results. Companies must invest in training their workforce to adapt to these technologies. Reports suggest that organizations with proper training see a 25% boost in operational efficiency. This points to a crucial area often overlooked in automation strategies.

**Tip:** Keep communication ongoing between team members. Open discussions often lead to better implementation of automated processes. Additionally, regularly assess your systems. Many companies forget to revisit their processes after initial installation. This can create gaps in efficiency over time.

Direct Automation Plc specializes in providing innovative automation solutions for various industries. Their key services include process automation, control system design, and systems integration. These offerings cater to manufacturing, energy, and logistics sectors. Each service aims to enhance efficiency and reduce human error.

Process automation simplifies complex routines. It allows businesses to streamline their operations. This service often involves software and hardware integration, creating a seamless workflow. Control system design focuses on developing user-friendly interfaces. This encourages operators to manage systems with ease, though not every design meets user expectations. Sometimes, adjustments are needed after implementation.

Systems integration is another essential service. It connects different technology systems to work together. It can be challenging, as compatibility issues often arise. Furthermore, the right configuration is crucial for optimal performance. Automation solutions should adapt, but they do not always fit perfectly into existing frameworks. Flexibility and continuous improvement are key concepts these services strive to achieve.

| Service | Description | Technology Used | Industry Applications |

|---|---|---|---|

| Robotics Process Automation (RPA) | Automating repetitive tasks across various applications. | AI, Machine Learning | Finance, Healthcare |

| Industrial Automation Solutions | Streamlining manufacturing processes to increase efficiency. | PLC, SCADA | Manufacturing, Energy |

| IoT Integration | Connecting devices for real-time data monitoring and control. | IoT Platforms, Cloud Computing | Smart Homes, Smart Cities |

| Data Analytics | Analyzing data to drive decision-making and improve operations. | Big Data Technologies, BI Tools | Retail, Telecommunications |

| Custom Software Development | Tailoring software solutions to meet specific client needs. | Development Frameworks, APIs | Various Industries |

Direct Automation Plc leverages advanced technology and software to optimize processes in various industries. Key components of this automation paradigm include IoT devices, AI algorithms, and cutting-edge data analytics tools. According to a recent industry report, the global automation market is expected to reach $200 billion by 2025, highlighting the growing importance of these tools in enhancing efficiency.

IoT devices play a crucial role in gathering real-time data. For example, sensors monitor equipment performance and report anomalies instantly. This allows companies to react promptly and reduce downtime. AI algorithms analyze this data, detecting patterns that human eyes might miss. Insights gained can lead to better decision-making, as many organizations have seen productivity improve by 20% after implementing AI-driven solutions.

However, challenges remain. Not all businesses can integrate these systems easily. There’s a learning curve associated with new technology. Moreover, data security concerns persist. Protecting sensitive information in an increasingly automated world is paramount. A survey indicated that 45% of companies worry about cybersecurity in automation. This calls for a thoughtful approach to adoption. Balancing innovation with security is essential to reap the full benefits of direct automation.

Direct automation solutions can transform how businesses operate. These systems streamline processes, reduce human error, and save time. Companies can increase efficiency and productivity by automating routine tasks. This approach often leads to significant cost savings.

Consider integrating smart systems into your workflow. Automated tools can handle repetitive jobs, allowing employees to focus on creative projects. This shift can inspire innovation and boost morale. However, it's crucial to train your team for a smooth transition. Resistance to change may arise, so open discussions about the benefits can help.

Metrics are essential in evaluating automation success. Monitor performance and gather feedback regularly. This practice will identify areas for improvement. Sometimes, the tool may not deliver as expected. In such cases, reassessing the approach is necessary. Cultivating a mindset of continuous improvement will benefit everyone involved.

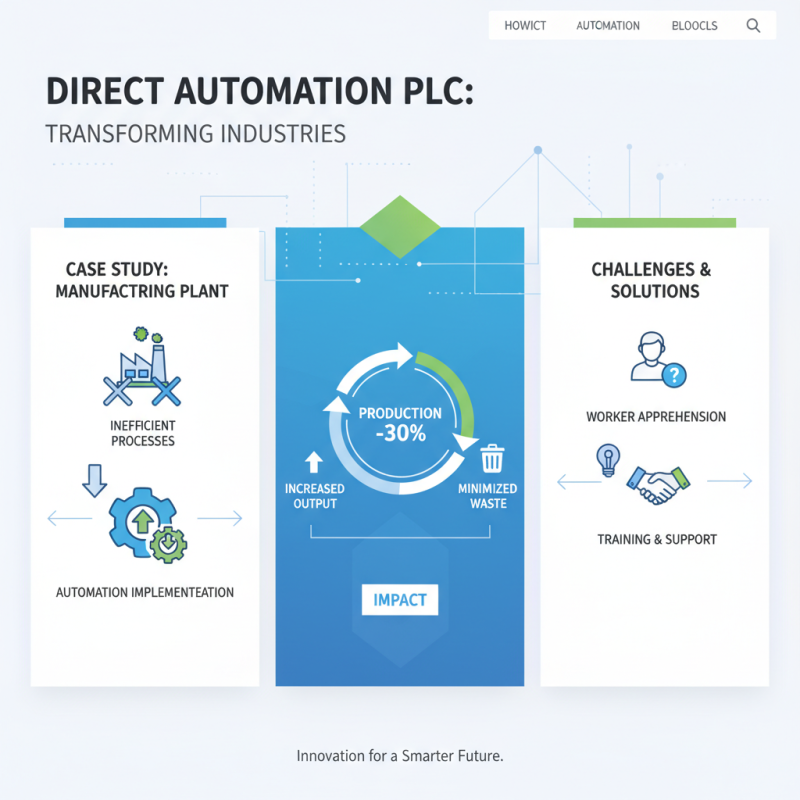

Direct Automation Plc has transformed various industries with its innovative solutions. One notable case study highlights a manufacturing plant that struggled with inefficient processes. They turned to Direct Automation Plc for help. The implementation of automation reduced production time by 30%. This increased output and minimized waste. However, not all aspects went smoothly. Some workers felt apprehensive about new technologies.

Another success story comes from a logistics company. They faced challenges with tracking shipments. Direct Automation Plc created a customized tracking system. This system enhanced visibility and efficiency. The company saw a 25% improvement in delivery times. Yet, adapting to this new system required thorough training.

Tips: When considering automation, prioritize employee involvement. Engage your team early in the process. Their insights can improve project outcomes. Also, focus on training. Continuous education fosters adaptability and success. Be prepared for hurdles. Automation is not always seamless. Reflect on these challenges to find effective solutions.