-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

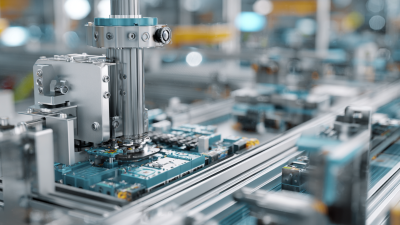

In the fast-paced landscape of modern industries, the integration of Direct Automation Plc has emerged as a pivotal solution for enhancing operational efficiency and productivity. According to a report by MarketsandMarkets, the global industrial automation market is projected to reach USD 296.70 billion by 2026, growing at a CAGR of 9.2%. This significant growth underscores the critical role of automation technologies in driving industry advancements. Direct Automation Plc, with its ability to streamline processes, reduce manual intervention, and optimize resource allocation, represents a key component in this paradigm shift. As organizations increasingly adopt smart manufacturing practices, leveraging Direct Automation Plc can result in substantial cost savings and improved output quality. With the industry's continuing evolution towards more integrated and automated systems, embracing Direct Automation Plc is not just a competitive advantage but a necessity for sustainable growth.

Direct automation, particularly through the implementation of Programmable Logic Controllers (PLC), is transforming the operational landscapes of modern industries. At its core, a PLC is a robust computer designed for industrial environments, capable of automating complex processes with precision and reliability. The ability to program these devices for various tasks enables manufacturers to streamline operations, reduce human error, and increase overall efficiency. Understanding the functional basics of PLCs allows industry professionals to maximize their capabilities and implement solutions tailored to specific production needs.

In addition to increasing productivity, direct automation through PLCs enhances data collection and analysis, providing insights into operational efficiency. This technological advancement allows real-time monitoring of equipment performance, facilitating proactive maintenance and minimizing downtime. Industries such as manufacturing, energy, and automotive are increasingly adopting PLC systems to maintain their competitive edge. By grasping the fundamentals of PLCs, organizations can harness the power of direct automation to not only optimize current processes but also innovate and adapt to the rapidly evolving industrial landscape.

Direct Automation PLC systems have become essential for modern industries striving for operational excellence. Implementing these systems allows for enhanced efficiency, real-time monitoring, and streamlined processes. Companies can significantly reduce manual intervention, leading to fewer errors and lower operational costs. The automation of routine tasks not only accelerates production but also frees up human resources for more strategic roles.

**Tip:** Begin by identifying the most repetitive and time-consuming tasks in your operations. Target these areas for automation to witness immediate improvements in productivity and workforce satisfaction.

Furthermore, Direct Automation PLC systems offer scalability, allowing industries to adapt quickly to changing demands. The integration of data analytics into these systems enables businesses to make informed decisions based on real-time insights. By leveraging automation, companies can optimize their supply chain, ensure product consistency, and maintain high standards of quality.

**Tip:** Regularly review system performance and analytics reports to identify further areas for improvement and expansion in your automation strategy. This proactive approach ensures that your business stays ahead in a competitive market.

Integrating Direct Automation PLC into modern industry operations can significantly enhance efficiency and productivity. The first step in this process is to assess current operational workflows and pinpoint areas where automation can drive improvements. By analyzing data and identifying repetitive tasks or bottlenecks, businesses can select specific processes that would benefit most from automation. This initial evaluation sets the stage for a smoother implementation, ensuring that the chosen PLC system aligns well with both operational needs and business goals.

Once the areas for automation are identified, the next step involves selecting the right Direct Automation PLC system tailored to those needs. It’s crucial to consider factors such as scalability, compatibility with existing machinery, and the ease of programming. Collaborating with automation experts can help businesses navigate these choices effectively. After the PLC system is selected, the integration phase can begin, which includes setting up the hardware, configuring software, and testing the system to ensure it functions seamlessly within operations. Continuous monitoring and adjustment post-integration further optimize performance, allowing industries to maximize the benefits of their automation investment.

In the modern industrial landscape, maximizing efficiency through automation is not just a luxury but a necessity. Direct Automation PLC (Programmable Logic Controllers) offers a streamlined approach to optimize operations, reduce errors, and save time. One of the best practices in leveraging Direct Automation PLC is to ensure seamless integration with existing systems. This integration allows for real-time data monitoring and analysis, which enhances decision-making processes and drives productivity levels upward.

Another effective strategy is to focus on continuous training and development of the personnel who handle these systems. As technology evolves, keeping your team informed about the latest features and functionalities is crucial. This not only empowers employees with the skills to utilize automation to its fullest potential but also cultivates an environment of innovation where feedback can lead to further enhancements. Automation is not a set-and-forget solution; consistent workforce engagement with automated systems leads to ever-increasing efficiency and adaptability, key components for thriving in today’s competitive market.

The landscape of manufacturing is rapidly evolving, driven by the principles of Industry 4.0. At the forefront of this transformation is the trend of direct automation, significantly enhancing operational efficiency across modern industries. As companies strive to integrate smart technologies into their processes, the global smart manufacturing market is expected to surge from $394.35 billion in 2025 to an impressive $998.99 billion by 2032, reflecting a robust CAGR of 14.2%. This growth is primarily fueled by the adoption of IoT, AI, and advanced robotics.

To successfully implement direct automation, businesses should focus on collaborating with technology providers to tailor solutions that meet specific needs. A key tip is to start small by automating less complex processes before scaling up to more advanced systems. This not only minimizes risks but also allows for gradual adjustment and optimization of operations.

Additionally, continuous training and upskilling of the workforce are crucial. Employees must adapt to new technologies and processes, ensuring they are equipped to leverage the benefits of automation. Investing in human capital is just as important as upgrading machinery, as it fosters a culture of innovation and adaptability in the face of rapid technological advancements.