-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the realm of electronics, a Motor Driver is not merely an accessory; it is a critical component. According to a recent industry report by Allied Market Research, the global motor driver market is projected to grow by 6.2% annually, reaching $12.85 billion by 2027. This data highlights the increasing demand for efficient motor control in various applications, from robotics to automation.

Expert Steve Johnson, a leading figure in motor technology, emphasizes the importance of motor drivers, stating, "Without a reliable motor driver, even the best designs can fail to deliver performance." This perspective underlines a common oversight among hobbyists and professionals alike. Many underestimate the impact of a quality motor driver on their projects. In many cases, poor performance stems from inadequate motor control.

Engineers and makers must consider the specifications of motor drivers. Factors such as voltage, current ratings, and integration capabilities are essential. Yet, many still approach motor drivers with a simplistic view. This often leads to frustration and inefficiencies. A deeper understanding can transform projects significantly. In conclusion, recognizing the pivotal role of a motor driver can bridge the gap between concept and execution.

Motor drivers play a crucial role in electronics projects. They act as intermediaries between microcontrollers and motors. Without them, your project may face frustration. Motor drivers regulate power, ensuring motors receive the right voltage and current. They translate signals from a microcontroller into motion. This process simplifies control over various types of motors.

When selecting a motor driver, consider the motor's specifications. Match the voltage and current requirements. Different motors need different control methods. Some require PWM signals for speed control. Others might need direction control. Understanding these details helps you avoid damaged components.

Tips: Always double-check connections before powering the circuit. Incorrect wiring can lead to failures. Testing the motor on a breadboard can save time. Plan your project carefully to ensure compatibility. Address potential issues early on. Failing to do so may result in wasted effort and resources.

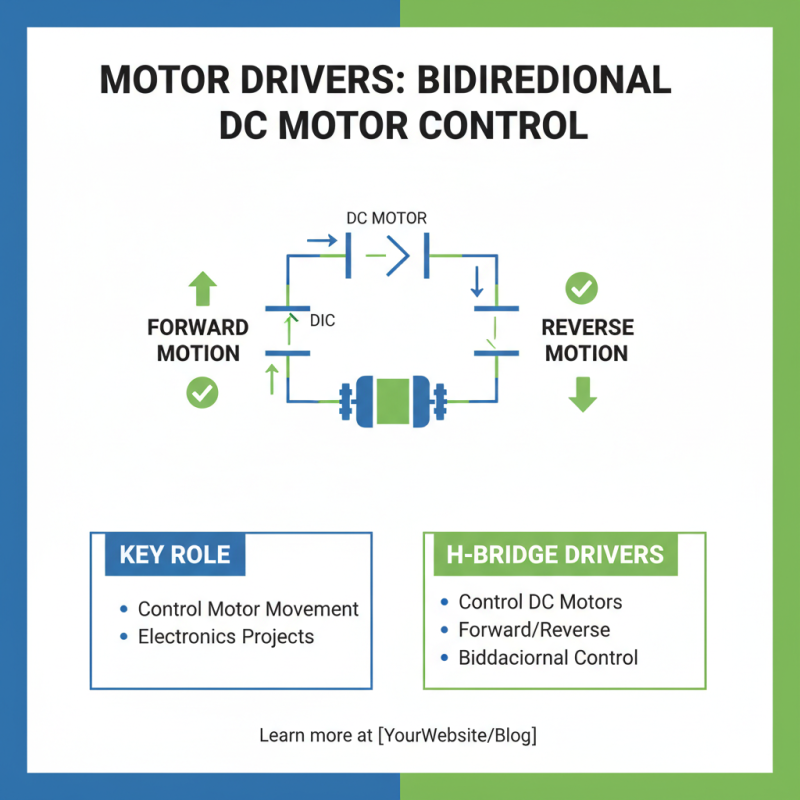

Motor drivers play a crucial role in electronics projects by controlling the movement of motors. Different types of motor drivers are available, each suited for specific applications. H-bridge drivers are popular for controlling DC motors. They allow for both forward and reverse motion. Understanding their setup can support bidirectional control.

Stepper motor drivers are another option. They enable precise control over motor position. This is ideal for robotics and CNC machines. Using stepper drivers can lead to smoother operations, but they may require more complex programming. It’s essential to match the driver type with your project needs.

Not every project needs the same driver. Choosing the right one may involve trial and error. Sometimes, a powerful motor may stall if it’s not paired with the correct driver. This could lead to frustration. Reflecting on the selection process can help refine future projects. Always consider load requirements and power supply.

When working on electronics projects, understanding motor drivers is crucial. They control motors in devices like robots and automation systems. Not all motor drivers are the same, and choosing the right one often involves examining key specifications.

For instance, voltage and current ratings determine whether the driver can handle your motor's requirements. High peak current capability can ensure sustained performance. Additionally, features like PWM (Pulse Width Modulation) give you precise control over speed. Some drivers even have thermal protection, preventing overheating during intense operation.

Another important factor is direction control. Many projects need to reverse the motor's direction. A driver offering easy direction switching can significantly simplify your circuit design. However, do not overlook the complexity that comes with more features. Ensure that your project can handle the added intricacies. This aspect requires careful thought and reflection during your design phase.

| Specification | Description | Importance |

|---|---|---|

| Voltage Rating | The maximum voltage the motor driver can handle. | Ensures compatibility with power supply and prevents damage. |

| Current Rating | The maximum current output the driver can deliver. | Determines the types of motors that can be driven. |

| Control Method | Types include PWM, analog voltage, or serial communication. | Affects how precisely the motor can be controlled. |

| Heat Dissipation | Ability of the driver to manage heat during operation. | Prevents overheating and ensures reliability. |

| Protection Features | Includes over-current, thermal, or reverse polarity protection. | Enhances safety and longevity of the motor and driver. |

| Interface Type | Can be GPIO, I2C, SPI, or a dedicated motor control interface. | Dictates ease of integration into projects. |

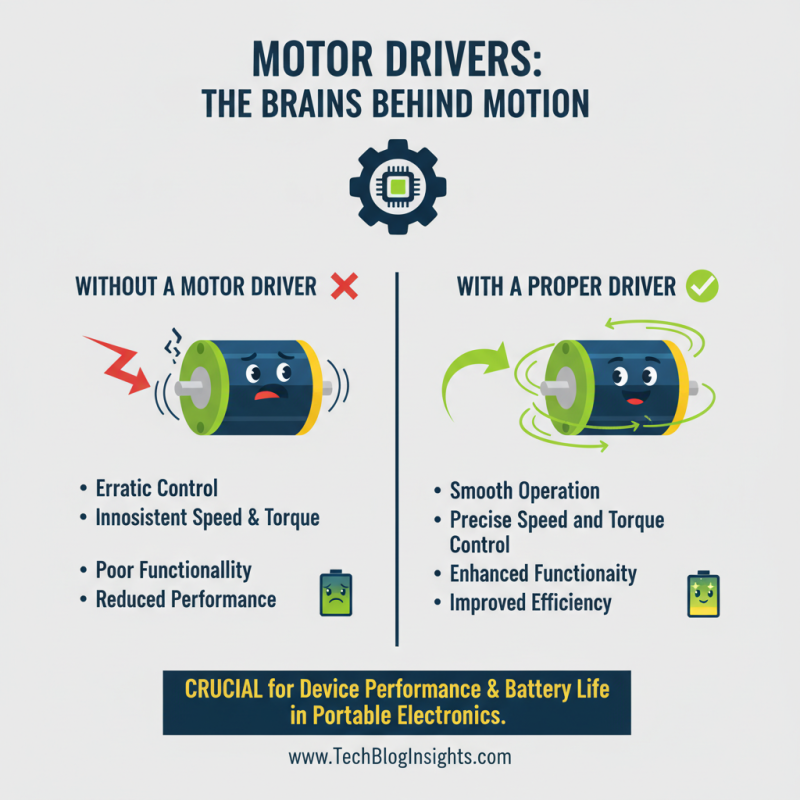

Motor drivers play a crucial role in electronics projects. They influence device performance and efficiency significantly. Without a suitable motor driver, the control of motors becomes erratic. This can lead to inconsistent speed and torque, affecting overall functionality. The right motor driver ensures smooth operation. Efficiency impacts battery life, especially in portable devices.

Tips: Always calculate current requirements for motors. Choose a driver that matches your project’s needs.

Using a motor driver can prevent overheating. Without it, motors could draw too much current. This leads to wasted energy and reduced performance. Additionally, incorrect voltage may damage components. Be cautious with specifications. Not all drivers handle the same power levels.

Tips: Read datasheets carefully. Understand your motor’s limits to avoid failures.

Sometimes, a basic driver may not suffice. Projects requiring precise movements need more advanced drivers. Failure to select the right option can lead to frustrations. Observe your project’s behavior. Make adjustments if necessary. Trial and error can be part of the learning journey.

The demand for motor driver applications in robotics is surging. Reports indicate that the global robotics market is expected to reach $210 billion by 2025. This growth is largely driven by advancements in automation and smart technologies. As robotics continues to evolve, effective motor control becomes essential.

Robotics relies heavily on precise movement. Motor drivers facilitate this by controlling speed and direction. For instance, automated guided vehicles require accurate positioning to function effectively. A study revealed that nearly 70% of robotics applications now utilize advanced motor drivers. This trend highlights their critical role in modern designs.

However, challenges persist. Many designers struggle with integrating these components effectively. Compatibility issues and power management can create hurdles. While the benefits are clear, navigating these complexities is not always easy. The evolving landscape demands that engineers remain adaptable.