-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

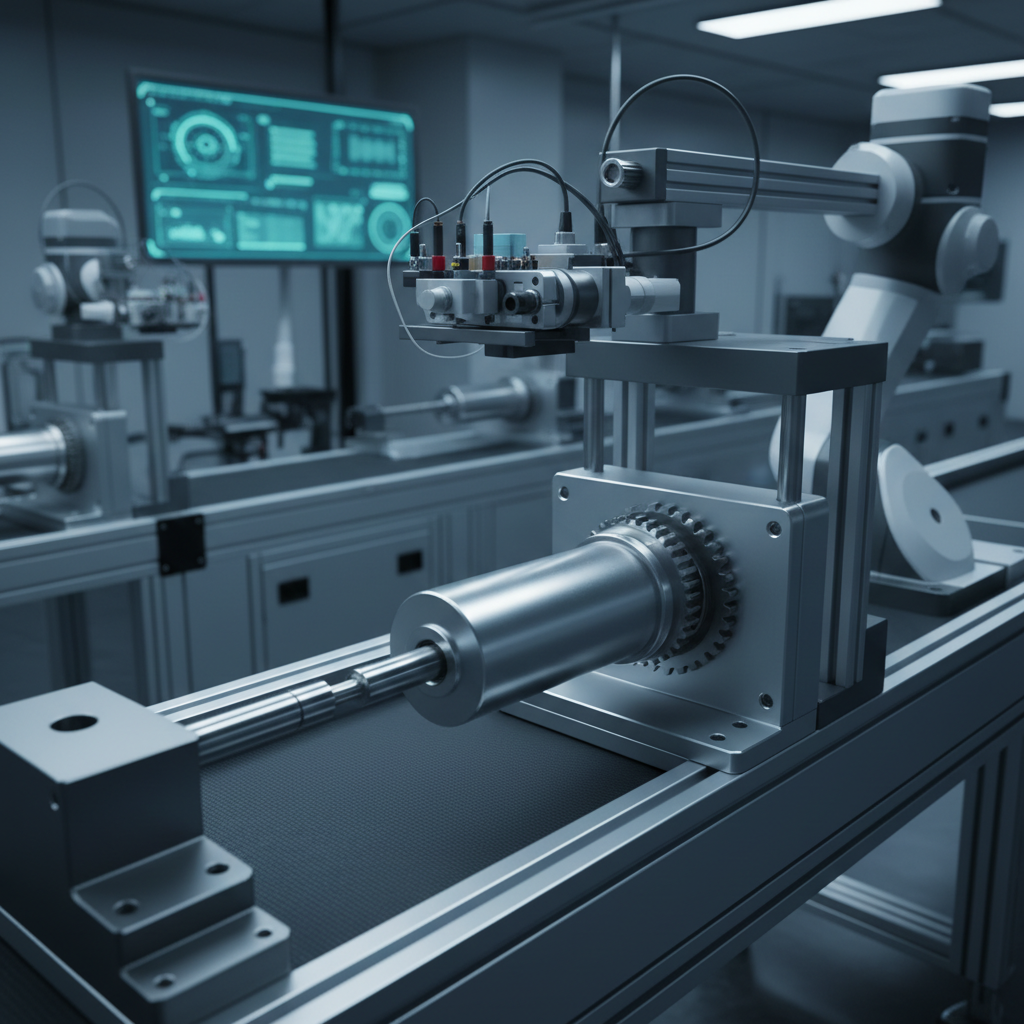

In the ever-evolving landscape of automation and robotics, the Servo Linear Actuator stands out as a vital component that enhances precision and reliability in motion control systems. According to a recent industry report by MarketsandMarkets, the global actuator market is projected to reach $70 billion by 2026, indicating a compound annual growth rate (CAGR) of 7.5% from 2021. As industries continue to seek innovative solutions for improved efficiency, the demand for advanced actuator technologies, particularly Servo Linear Actuators, is rapidly increasing.

Selecting the right Servo Linear Actuator for a project can significantly impact overall performance and success. These devices are instrumental in applications ranging from assembly lines in manufacturing to advanced robotics in medical devices. Research from Technavio highlights that the growing trend of automation across various sectors is expected to boost the adoption of Servo Linear Actuators, as they offer the precision and control necessary for sophisticated hydraulic and pneumatic systems.

Understanding the essential factors in choosing a Servo Linear Actuator is critical for engineers and project managers alike. With the right guidance, stakeholders can navigate through the numerous options available in the market, ensuring their projects benefit from enhanced productivity and reduced operational costs. This article provides ten essential tips to aid in this decision-making process, paving the way for successful project outcomes in a competitive landscape.

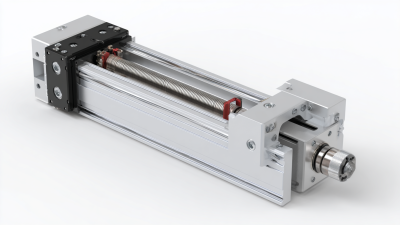

When selecting a servo linear actuator for your project, understanding the various types available is crucial. Servo linear actuators come in several forms, including electromechanical, hydraulic, and pneumatic types. Electromechanical actuators utilize electric motors to drive a lead screw or belt, offering high precision and a compact design suitable for applications where noise and maintenance are concerns. These are often favored for tasks requiring exact positioning, such as robotics and automation.

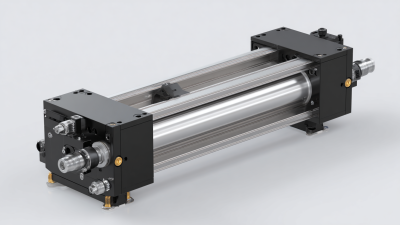

On the other hand, hydraulic actuators are capable of delivering high force output and are ideal for heavy-duty applications.

They operate using pressurized fluid, making them suitable for tasks that require heavy lifting or movement.

However, they may necessitate more maintenance due to potential fluid leaks.

Pneumatic actuators, which rely on compressed air, provide quick and smooth movement, making them ideal for applications needing fast cycles.

They are often seen in manufacturing environments where speed is essential.

By understanding these fundamental types, you can choose the right servo linear actuator that aligns with your project's specific needs and operational environment.

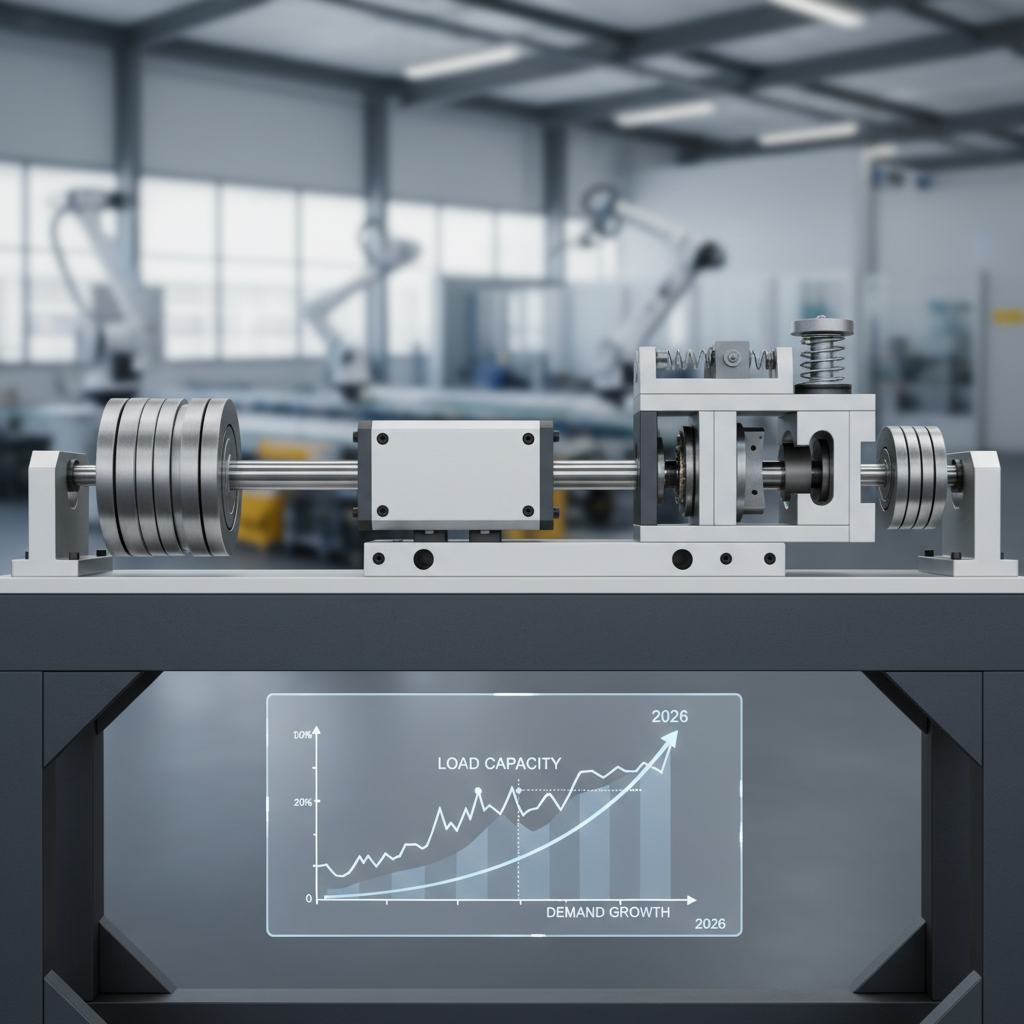

When selecting a servo linear actuator for a project, understanding load capacity and speed requirements is crucial. According to a recent market analysis by ResearchAndMarkets, the demand for servo actuators is expected to increase by 7.5% annually through 2026. This growth can be attributed to advancements in automation technology, emphasizing the need for actuators that can effectively handle varying load conditions.

Load capacity is not just about the maximum weight the actuator can lift; it involves assessing torque, potential dynamical loads, and how these elements interact during operation. A thorough understanding of the specific requirements of your application, including peak loads and operational cycles, will ensure you select the appropriate actuator that maintains performance without risk of failure.

Speed requirements also play a vital role in actuator selection, as it directly affects overall system efficiency. Research shows that servo linear actuators typically offer speed ranges from 1 to 600 mm/s, with some advanced models achieving even higher velocities. When choosing an actuator, consider not just the desired speed, but also the acceleration and deceleration profiles, as these parameters influence the actuator's responsiveness and longevity.

Selecting an actuator with the right balance of speed and control can enhance productivity while minimizing wear and tear, aligning with the growing demand for precision in industries like robotics and manufacturing, which are projected to represent a significant portion of the actuator market.

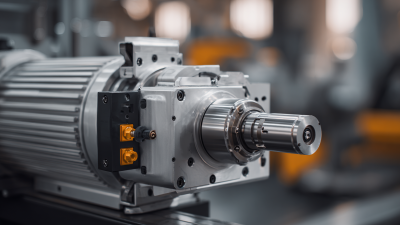

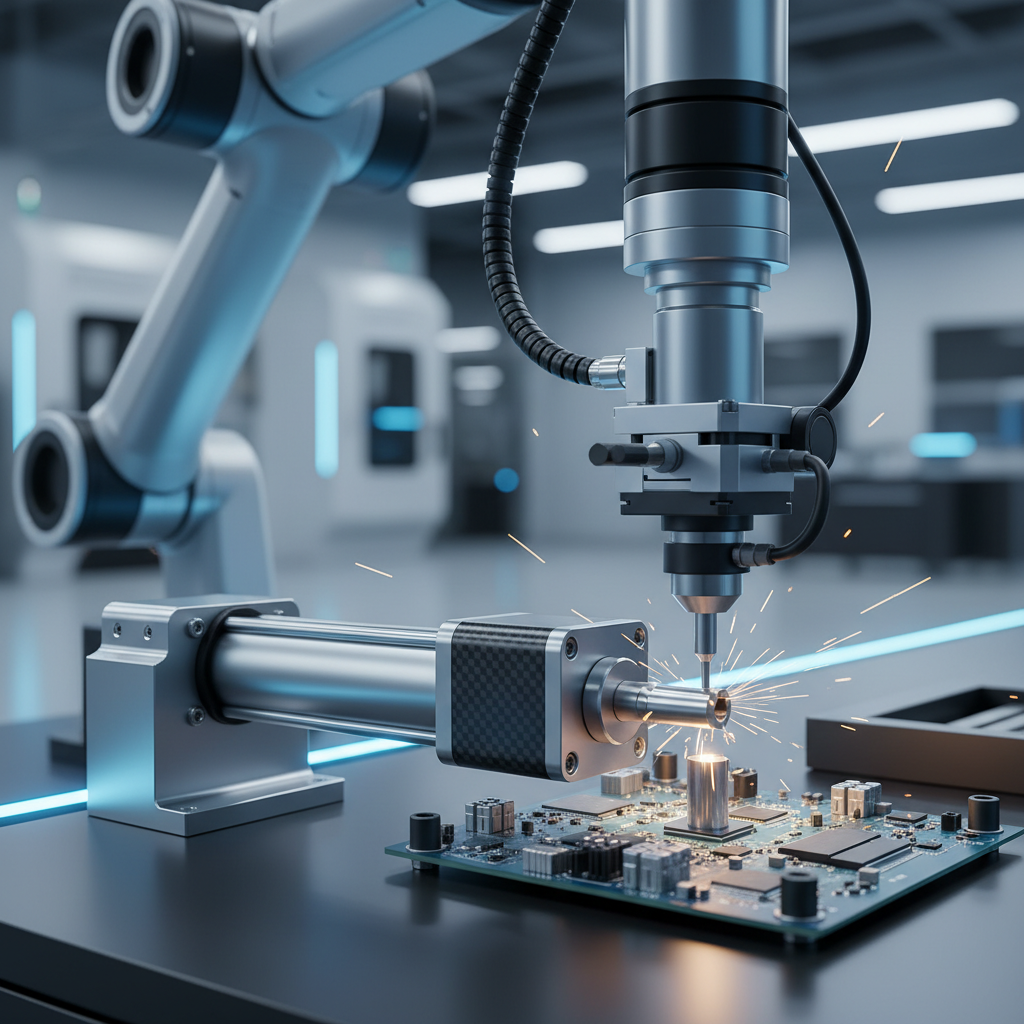

When selecting the right servo linear actuator for your project, understanding the importance of precision and accuracy is paramount. A recent report from the International Federation of Robotics highlights that precision automation is crucial in industries such as manufacturing, where even the smallest deviation can lead to significant production errors. Servo linear actuators are designed to provide high levels of control, ensuring that tasks are performed with meticulous accuracy. According to the report, systems that utilize servo technology can improve productivity by up to 25% compared to traditional systems.

To enhance your selection process, consider these essential tips: first, assess the required speed and load capacity of the actuator. A mismatch between these parameters can affect both performance and lifecycle. Next, evaluate the feedback mechanism of the actuator; models equipped with high-resolution encoders offer superior position control and accuracy. This is where servo linear actuators excel, providing the nuanced control necessary for applications like robotics and automated assembly lines. Making informed choices based on these factors will not only meet specific project demands but also optimize efficiency in the long run.

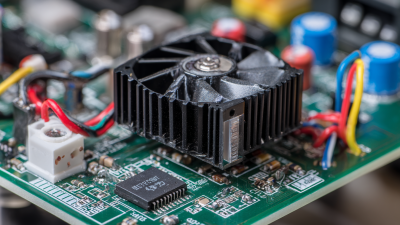

When selecting a servo linear actuator for your project, evaluating control systems and compatibility is crucial to ensure optimal performance and functionality. Begin by assessing the type of control system you plan to implement. Will it be a closed-loop system for precise positioning, or an open-loop system for simpler applications? Understanding your project's specific needs will help you identify the most suitable actuator. Look for options that offer flexibility in control methods, such as pulse-width modulation (PWM) or analog signal input, to align with your project requirements.

Compatibility with your existing components is another vital aspect. Check whether the actuator's voltage and current ratings match your system's specifications. Additionally, consider the interface protocols, such as RS-232 or CAN bus, that your control system utilizes. Ensuring seamless communication between the actuator and other devices is essential for maintaining system integrity and preventing costly errors. By thoroughly evaluating these elements, you can make an informed decision that enhances the overall efficiency of your project.

| Criteria | Considerations | Recommended Values |

|---|---|---|

| Load Capacity | Determine the maximum load to be moved | 5 - 2000 N |

| Stroke Length | Distance the actuator needs to travel | 50 mm - 1000 mm |

| Speed | Required speed of actuation | 5 - 100 mm/s |

| Power Supply | Voltage and current requirements | 12 - 48 VDC |

| Duty Cycle | Operational vs. rest time | 10% - 100% |

| Control Type | Open-loop vs. closed-loop control | Closed-loop preferred |

| Feedback Mechanism | Types of feedback available | Potentiometer, Encoder |

| Compatibility | Ensure actuator matches with other components | Check interface standards |

| Environmental Rating | Operating conditions (temperature, dust, moisture) | IP54 and above |

| Cost | Budget constraints for the project | $100 - $1000 |

When selecting a servo linear actuator for your project, one crucial aspect to consider is the environmental conditions in which the actuator will operate. Different environments, whether they involve extreme temperatures, humidity, or contamination, can significantly affect actuator performance. For example, an actuator working in a high-humidity environment may require additional sealing to prevent moisture intrusion, which could lead to malfunction or reduced lifespan. Similarly, if the actuator is exposed to dust or corrosive materials, choosing a model with suitable protective features is essential to ensure reliability over time.

Moreover, understanding the specific application requirements is vital in determining the appropriate actuator type. If the project involves outdoor use, aspects such as UV resistance and weatherproofing capabilities become important. In contrast, for applications in controlled environments, standard actuators may suffice. By thoroughly assessing these conditions and their impact on performance, engineers can make informed choices that enhance the efficiency and longevity of their systems while minimizing the risk of operational failures.

This chart illustrates the effect of different environmental conditions such as temperature, humidity, and dust levels on the performance and reliability of servo linear actuators.