-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the rapidly evolving field of automation and control systems, the demand for advanced servo drives continues to surge, as highlighted by a recent market research report from Research and Markets, which anticipates that the global servo drive market will reach $11.5 billion by 2025, growing at a CAGR of 4.4%. As businesses strive for enhanced precision and efficiency in their operations, the need for diverse solutions that extend beyond standard servo drive offerings becomes critical. This blog will explore various alternatives to conventional servo drives, including their applications in robotics, aerospace, and manufacturing, as organizations look to innovate and adapt to the challenges of modern industry. By examining these diverse options, we aim to provide insights into how companies can leverage tailored servo drive solutions to optimize performance and drive competitive advantage.

As industries increasingly look for enhanced efficiency and precision, advanced servo drive technologies are stepping into the spotlight, offering benefits that extend beyond traditional solutions. The global servo drive market is anticipated to reach around USD 21.97 billion by 2034, driven by a range of applications including robotics, packaging, and automotive sectors. The ongoing innovations in servo drives are not just about power, but also about delivering compact solutions that optimize performance in tight spaces.

One significant trend in this evolution is the emergence of micro-sized servo drives, spurred by technological advancements such as Moore's Law. These miniaturized components maintain high performance while occupying minimal physical space, making them ideal for modern applications. Industries are capitalizing on these developments to implement more sophisticated and efficient systems, ultimately leading to productivity gains and reduced operational costs. The integration of micro-sized servo drives is an exciting development within the broader context of automation, showcasing how advanced servo technology is reshaping industrial applications.

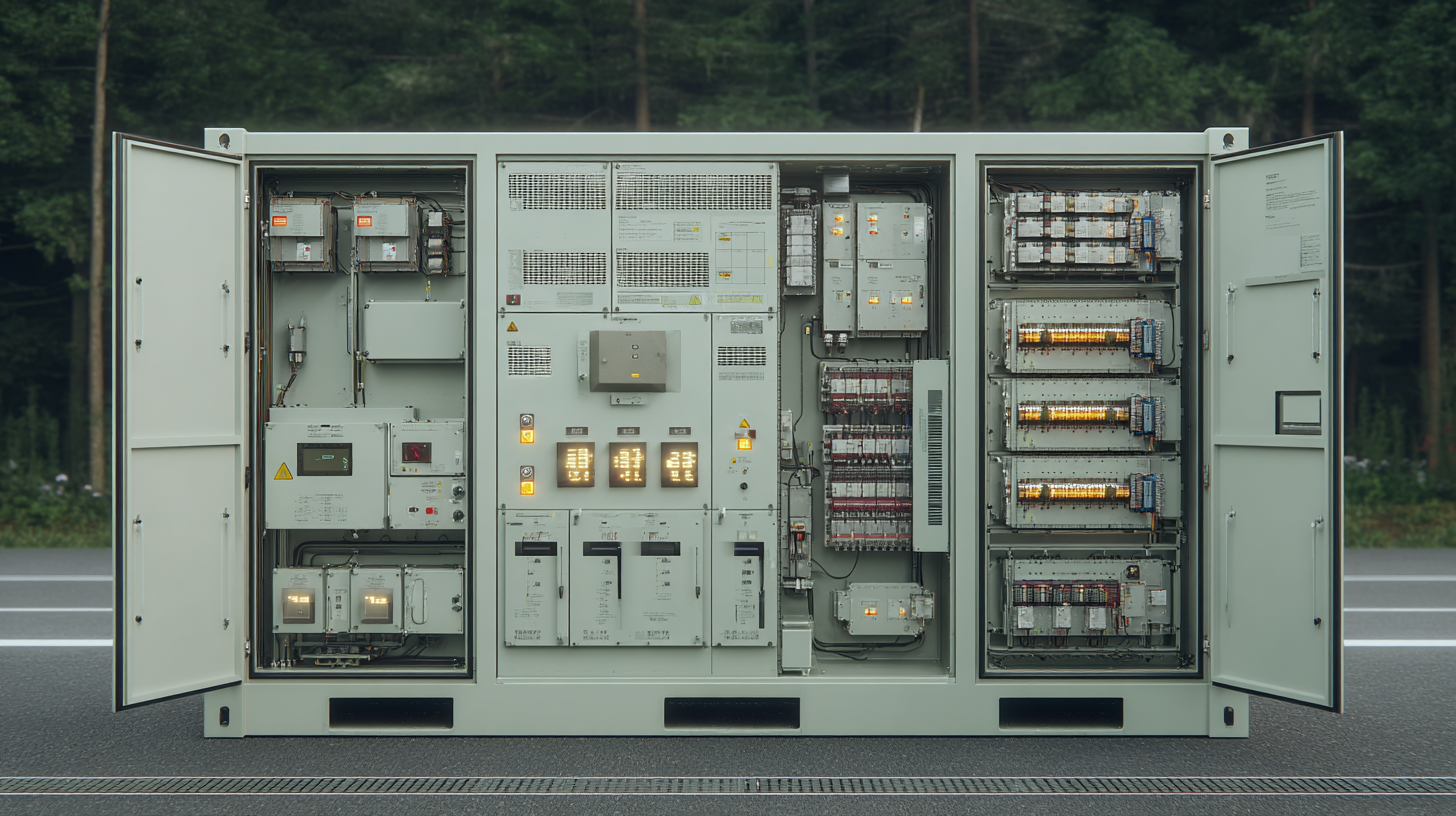

The performance of servo drives is crucial in various industrial applications, where efficiency and precision are often paramount. A comparative analysis of different types of servo drives reveals significant variations in their efficiency and performance metrics. Recent industry reports indicate that advanced servo drive systems can achieve up to 95% energy efficiency, which not only reduces operational costs but also minimizes heat generation, contributing to a longer lifespan of the machinery.

One key aspect to consider when selecting a servo drive is the implementation of pulse-width modulation (PWM) techniques in two-level voltage source inverters. These technologies allow for precise control of the motor's speed and torque, achieving smoother operation and reduced radial forces. Additionally, improved design methodologies can further enhance performance by optimizing the inverter circuit for reduced harmonic distortion, thereby improving overall system stability.

Tips for selecting the right servo drive include evaluating the specific demands of your application, considering both torque and speed requirements. It's essential to conduct thorough testing under real operational conditions to ensure that the chosen drive meets or exceeds performance expectations. Regular updates on industry trends and advancements in drive technology can also help inform better decisions in drive selection, aligning with the latest efficiency standards.

As the Automation Expo 2025 approaches, the spotlight on smart servo drives and their integration with Industry 4.0 standards has never been more prominent. The rapid evolution of motion control technologies is reshaping high-speed automation landscapes. According to recent market analyses, the global market for AC servo motors and drives was valued at approximately USD 15.2 billion in 2024 and is projected to grow at a rate of 6.6% annually until 2034. This growth is largely driven by advancements in servo systems that enhance precision and efficiency in automated processes.

In the context of Industry 4.0, smart servo drives are pivotal in achieving seamless connectivity and data exchange across manufacturing systems. The increasing demand for energy-efficient and IoT-enabled motor solutions reflects a significant trend toward sustainable manufacturing practices. Reports indicate that the smart motors market is poised to reach USD 3.51 billion by 2032, highlighting the industry's shift towards smarter, more integrated automation solutions that align with contemporary technological standards. This strategic integration not only enhances operational efficiency but also positions companies to stay competitive in an increasingly automated industrial environment.

| Option | Description | Benefits | Industry 4.0 Integration | Common Applications |

|---|---|---|---|---|

| Standard Servo Drives | Traditional servo motors that provide basic position control. | Cost-effective; Reliable performance. | Limited; Basic communication protocols. | Robotics, CNC machines. |

| Smart Servo Drives | Advanced servo motors with integrated sensors for real-time data. | Enhanced precision; Self-diagnostics. | Seamless; Enables predictive maintenance. | Automation, Packaging. |

| Networked Servo Drives | Servo motors connected through a network for synchronized control. | Improved coordination; Scalability. | Full integration; Supports IoT applications. | Multi-axis machines, Robotics. |

| Adaptive Servo Drives | Servo motors that automatically adjust to varying load conditions. | Energy efficiency; Increased uptime. | Intelligent; Facilitates real-time adjustments. | Textile machines, Conveyor systems. |

| AI-Driven Servo Drives | Servo drives utilizing machine learning algorithms for optimal performance. | Superior precision; Learning capacity. | High adaptability; Supports complex systems. | Smart factories, Advanced robotics. |

In the rapidly advancing world of automation and robotics, the integration of servo drives has become critical for enhancing operational efficiency. These drives play a pivotal role in improving precision and responsiveness in robotic applications. The ongoing development in servo technologies, such as ultra-fast and compact models, allows for their use in various applications ranging from industrial grippers to surgical robots, proving their versatility and effectiveness in different sectors.

When considering servo drive implementations, it’s essential to assess the specific requirements of your application. For optimal performance, focus on the torque and power density of the motors, as these factors significantly impact the overall efficiency and responsiveness of the robotic system. Additionally, keep an eye on the future trends of motion control, as advancements in miniaturization and smart technologies are poised to redefine the landscape of automation.

Investing in high-performance servo drives can yield substantial operational savings. By embracing energy-efficient solutions, manufacturers can significantly reduce their operational costs, thus contributing to a sustainable production environment. Exploring beyond standard solutions can not only enhance automation processes but also pave the way for innovative applications in the ever-evolving field of robotics.

As industries increasingly shift towards sustainable practices, the design of servo drives is also evolving to reflect this imperative. Emerging trends focus on leveraging innovative materials and advanced manufacturing techniques to produce more energy-efficient systems. For example, the integration of lightweight components not only reduces energy consumption but also improves the overall performance of servo drives. This shift towards sustainability is not merely a trend; it represents a significant commitment by manufacturers to reduce their environmental impact while maintaining high standards of performance and reliability.

Cost-effectiveness is another critical consideration in the evolution of servo drive design. As competition intensifies across various sectors, companies are seeking ways to optimize their operations without compromising quality. This has led to the development of more affordable servo drives that utilize scalable technologies, allowing businesses to implement solutions that meet their specific needs without overextending their budgets. The focus on modular designs enables manufacturers to provide customizable options, ensuring that clients receive the best value for their investments while adapting to future technological advancements. Together, sustainability and cost-effectiveness are shaping a new era in servo drive innovation, offering businesses the tools they need to thrive in a rapidly changing landscape.

This bar chart represents the emerging trends in servo drive design, highlighting various options beyond standard solutions, focusing on aspects such as sustainability and cost-effectiveness. The data showcases the increasing significance of eco-friendly materials, energy efficiency, and IoT integration, aiming to drive innovation in the sector.