-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

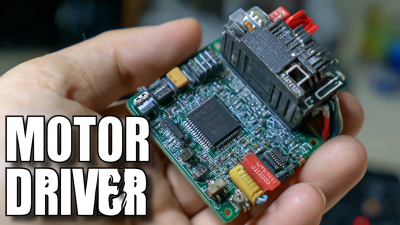

In the world of robotics and electronics, understanding the different types of Motor Drivers is essential for any enthusiast or professional. Motor Drivers serve as the vital link between a control system and the actual motors they drive, enabling precise control over speed, direction, and torque. This ultimate guide dives deep into the various Motor Driver variants available in the market today, highlighting their unique features and applications. Whether you are working on a simple DIY project or a complex robotic system, selecting the right Motor Driver can significantly impact the performance and efficiency of your design. Join us as we explore the intricacies of these crucial components, providing you with the knowledge needed to make informed decisions and enhance your projects.

When exploring the world of motor drivers, it's essential to grasp the distinct types of motors they support: stepper, DC, and servo motors. Each of these motor types serves specific applications and exhibits unique operational characteristics.

Stepper motors, for instance, excel in precision control, making them ideal for applications requiring exact positioning, such as 3D printers and CNC machines. Their ability to move in discrete steps allows for fine control over rotation.

Stepper motors, for instance, excel in precision control, making them ideal for applications requiring exact positioning, such as 3D printers and CNC machines. Their ability to move in discrete steps allows for fine control over rotation.

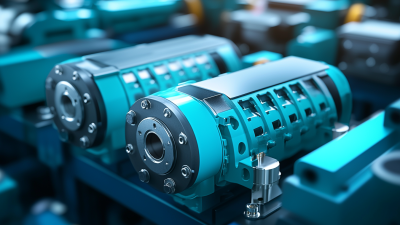

On the other hand, DC motors are known for their simplicity and efficiency. They are widely used in household appliances, toys, and robotics. Their speed can be easily adjusted by varying the voltage supplied, which makes them suitable for applications that require variable speed control. However, DC motors typically lack the positional feedback mechanisms found in other motors, making them less suitable for precise applications.

Servo motors, distinguished by their integrated feedback control systems, are engineered for applications that demand high precision and torque, such as robotic arms and automated machinery. They provide a combination of both speed and position control, making them indispensable in automation fields. Understanding these motor driver types can significantly enhance the design and functionality of various robotic and automated systems.

When selecting a motor driver, understanding the key technical specifications such as voltage, current ratings, and efficiency is crucial.

Voltage ratings indicate the maximum voltage that the driver can handle, which directly influences the performance of the motor it controls. For instance, a driver that operates at a higher voltage can drive a motor with higher speed and torque, making it essential for applications requiring significant power. However, it's important to match the voltage rating with the motor's requirements to avoid damage and ensure optimal performance.

Current ratings are equally important, as they determine the maximum current the motor driver can supply. Exceeding this rating risks overheating and damaging both the driver and the motor. For applications demanding high start-up torque or continuous heavy loads, selecting a driver with adequate current capability ensures reliability and longevity. Additionally, efficiency is a vital specification, as it reflects how well the driver converts electrical energy into mechanical energy. Higher efficiency not only reduces energy consumption but also minimizes heat generation, resulting in improved performance and longer operational lifespan. Therefore, careful consideration of these factors will lead to a more effective motor driver selection that meets specific application needs.

When selecting a motor driver, understanding the torque and speed characteristics is crucial for optimizing performance in various applications. Different motor driver variants offer unique capabilities that can significantly influence the operational efficiency of motors. For instance, high-torque motor drivers are essential when applications require overcoming substantial loads. These drivers often employ advanced control strategies, allowing for instantaneous torque management and ensuring that the motor can deliver consistent force even at low speeds.

Conversely, speed-centric motor drivers prioritize quick acceleration and high RPM outputs. These drivers utilize features like pulse-width modulation (PWM) for precise speed control, making them ideal for applications necessitating rapid movements, such as robotic arms or conveyor belts. A comparative analysis of these performance characteristics reveals that while torque is paramount for heavy-duty tasks, speed is critical for dynamic operations. Ultimately, choosing the right motor driver variant depends on the specific demands of the application, necessitating a careful evaluation of both torque and speed features to achieve the desired performance outcomes.

In the realm of embedded control solutions, integrating motor drivers with microcontrollers stands as a critical aspect of modern automation and robotics. According to a report from MarketsandMarkets, the global motor driver market is expected to grow from $2.3 billion in 2020 to $3.4 billion by 2025, driven by the increasing demand for automation in industries such as automotive, aerospace, and manufacturing. This growth highlights the importance of selecting the right motor driver to match the specific requirements of microcontroller applications, including voltage, current ratings, and control strategies.

When integrating motor drivers with microcontrollers, engineers must consider various unique features offered by different motor driver variants. For instance, some drivers provide advanced features such as PWM (Pulse Width Modulation) control, which allows for efficient speed regulation while minimizing power consumption. Additionally, the implementation of feedback mechanisms, such as encoders, can enhance precision in applications requiring high accuracy. Research from Allied Market Research emphasizes that the increasing adoption of IoT devices is also expanding the market for integrated motor control solutions, enabling smarter and more responsive systems that can adapt in real-time to changing operational conditions.

| Motor Driver Type | Max Current (A) | Voltage Range (V) | Control Method | Key Features |

|---|---|---|---|---|

| H-Bridge Driver | 15 | 5 - 30 | PWM | Bidirectional control, compact size |

| Step-Down Driver | 10 | 8 - 40 | Voltage Control | High efficiency, thermal protection |

| Brushless DC Driver | 20 | 12 - 50 | Sensorless or with Hall effect | Quiet operation, high torque |

| Dual Motor Driver | 12 | 6 - 24 | PWM | Control two motors simultaneously |

| Smart Motor Controller | 25 | 10 - 60 | CAN, PWM | Integrated positioning feedback, programmable |

Emerging trends in motor driver technology are increasingly shaped by the rapid integration of IoT and smart automation. According to a recent report by MarketsandMarkets, the global IoT in the motor driver market is projected to grow from $2.8 billion in 2023 to $9.0 billion by 2028, at a CAGR of 26.4%. This growth is primarily driven by the surge in demand for smart appliances and automated systems across various industries including automotive, industrial, and consumer electronics. As companies aim for increased efficiency and connectivity, motor drivers equipped with IoT capabilities are becoming essential components in modern designs.

Furthermore, innovations in motor driver features are enabling better adaptability to smart automation platforms. Technologies such as AI-driven algorithms are now being integrated into motor drivers, providing enhanced control and predictive maintenance capabilities. A report by Allied Market Research reveals that the smart automation market, which heavily relies on advanced motor drivers, is expected to reach $102.5 billion by 2028. This convergence not only optimizes performance but also reduces energy consumption, meeting the industry's escalating demand for sustainable solutions. As these trends evolve, they will redefine how applications leverage motor driver variants, setting new standards for performance and interoperability in automation systems.