-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

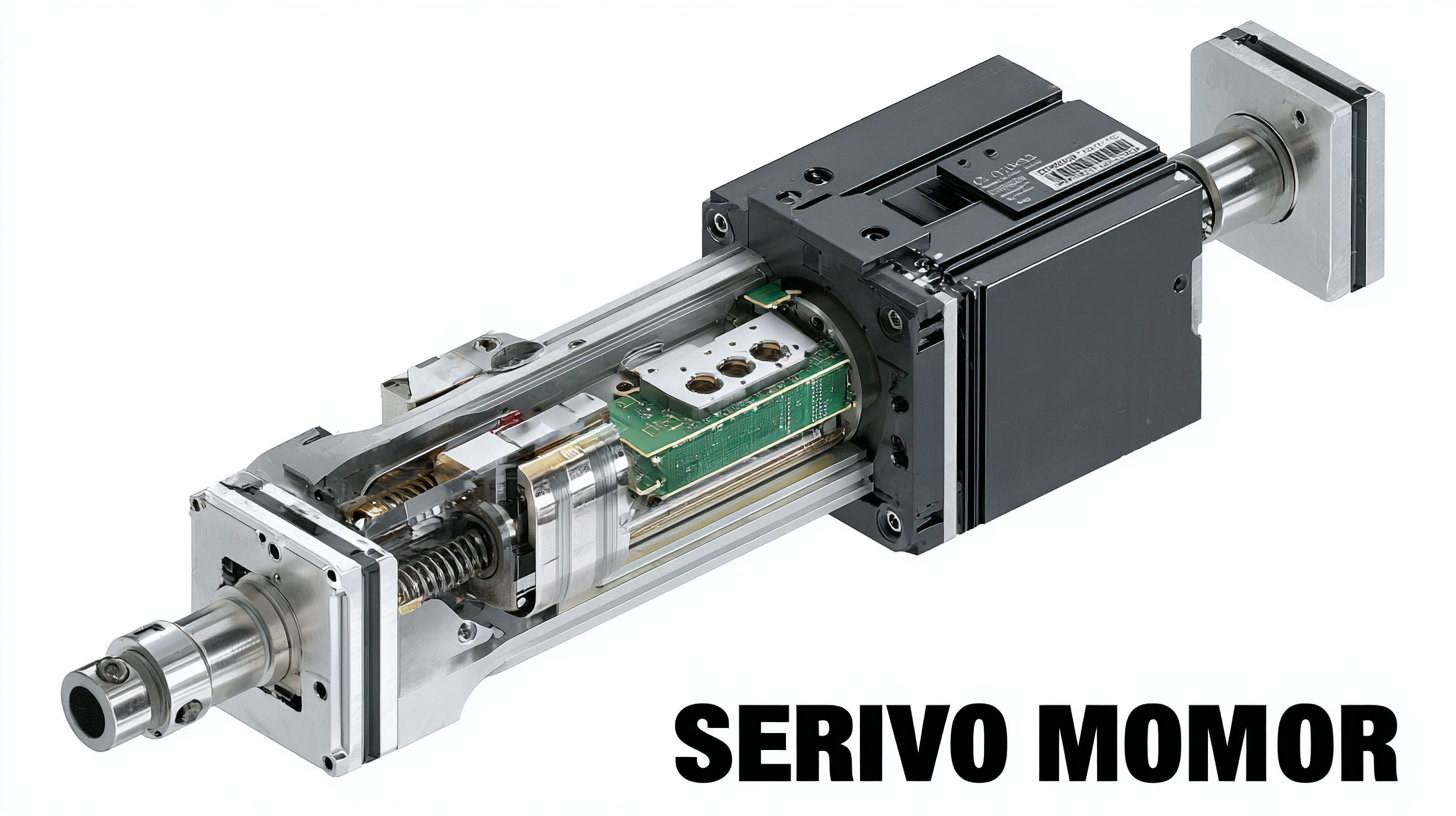

In today's rapidly evolving industrial landscape, the demand for precision and efficiency is paramount, making the selection of the right Linear Servo Motor pivotal for various applications. According to a report by MarketsandMarkets, the global linear motor market is projected to grow from USD 1.9 billion in 2020 to USD 4.3 billion by 2025, at a CAGR of 17.5%. This growth is fueled by significant advancements in automation and robotics, where linear servo motors are increasingly utilized for their high responsiveness and accuracy. As manufacturers strive for excellence, particularly those emphasizing quality through "Made in China" products that lead global exports, understanding the intricacies of selecting the best linear servo motor becomes essential. This guide aims to equip engineers and procurement specialists with the knowledge necessary to navigate this critical decision, ensuring optimal performance in their specific applications.

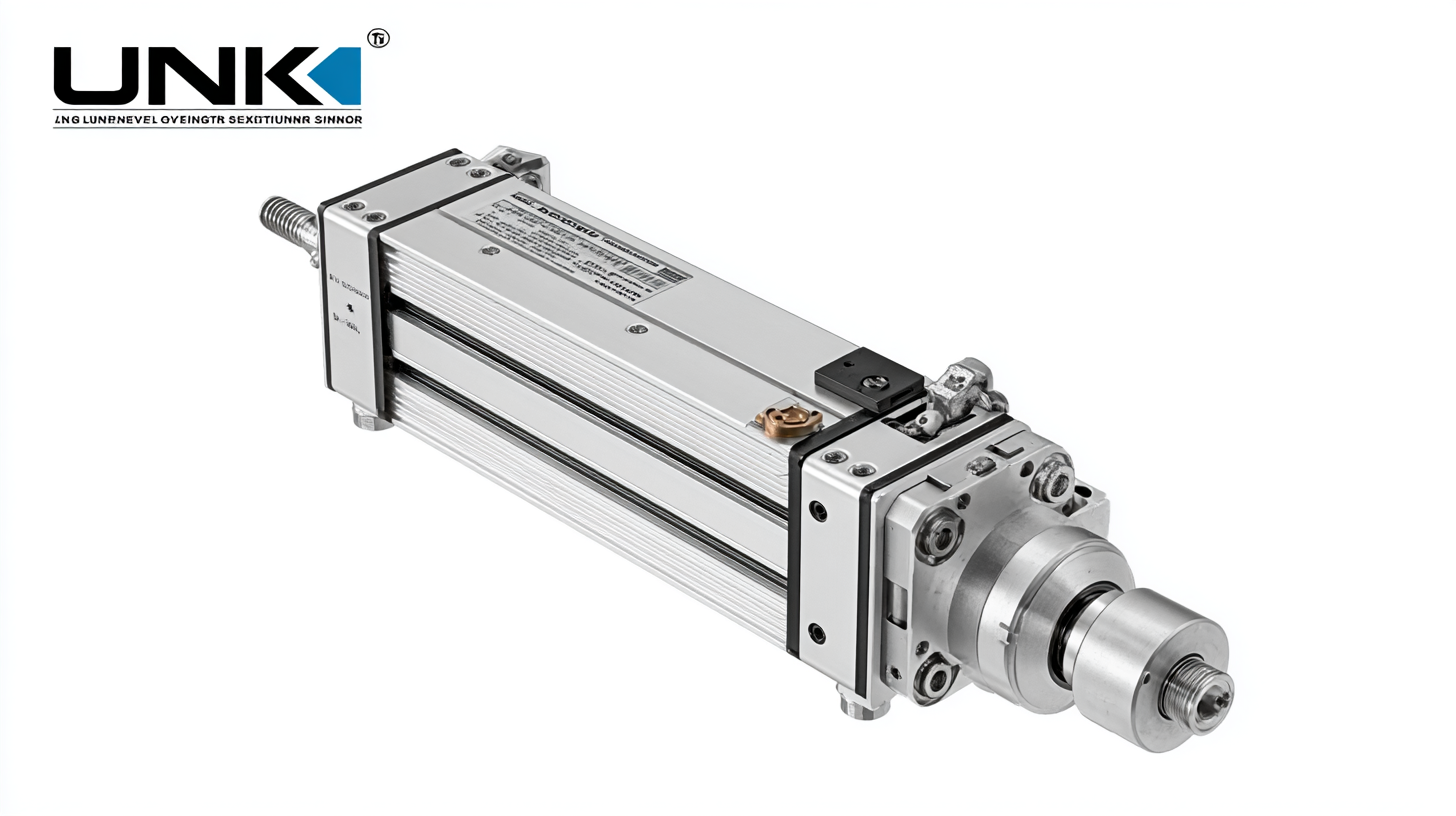

When selecting the best linear servo motor for your applications, it is crucial to understand your specific requirements. This involves assessing the necessary force, speed, and precision needed for your project. For instance, recent advancements in compact linear voice coil servo motors highlight their relevance in applications requiring high accuracy and repeatability, such as laser beam steering and optical focusing. These attributes make them ideal for high-performance tasks that demand quick response times and minimal delay.

Additionally, consider the size and weight constraints of your application. Innovations in miniature linear servo motors are providing solutions that maintain high performance in smaller packages, making them suitable for applications ranging from robotics to manufacturing systems. With various options available, including those specifically designed for test and measurement or wafer handling, it's essential to evaluate the complete range to find the perfect match for your operational needs. The advancements in linear motion control technology ensure that precision and efficiency can be achieved, regardless of the scale of the application.

When selecting a linear servo motor for your applications, the qualities of your supplier can significantly impact performance and reliability. According to a report by MarketsandMarkets, the global linear motor market is projected to reach USD 1.73 billion by 2025, emphasizing the importance of choosing an adept supplier who understands the dynamic landscape of this technology. Look for suppliers with a proven track record in providing high-efficiency motors and superior thermal management systems, as these features contribute to the longevity and stability of your operations.

**Tip:** Always inquire about your supplier's experience in your specific industry. A supplier familiar with your application challenges is more likely to provide tailored solutions that can enhance performance and reduce downtime.

Additionally, verify the supplier's commitment to quality assurance processes. A robust quality management system ensures that every motor adheres to strict performance standards. The International Electrotechnical Commission (IEC) standards outline critical testing parameters that reliable suppliers should meet, ensuring their products perform optimally in critical applications.

**Tip:** Request documentation that showcases compliance with industry standards, such as ISO 9001 certifications, which indicate that the supplier has established a quality management framework essential for delivering high-grade products.

When selecting the best linear servo motor for your applications, evaluating the experience and reputation of potential suppliers is crucial. A supplier’s market presence often reflects their expertise in the industry, including their history of innovations and development in linear motion technologies. Established suppliers typically have a track record of reliability, showcasing products that have been tested and proven in various demanding applications. Their long-standing presence often correlates with the comprehensive understanding of client needs, enabling them to provide tailored solutions that align with your specific project requirements.

Additionally, customer reviews, testimonials, and case studies can offer insightful perspectives into a supplier’s reputation. Understanding how previous clients have fared with their products and services can help gauge the quality and performance you can expect. Suppliers that actively engage with their customers and seek feedback demonstrate a commitment to continuous improvement, further enhancing their credibility within the market. Therefore, investing time in evaluating supplier experience and reputation can not only help in selecting the right linear servo motor but also assure you of robust after-sales support and trouble-free operation in your applications.

When selecting the best linear servo motor for your applications, it is crucial to evaluate customer service and support capabilities offered by manufacturers. According to a report by Precision Motion, 27% of businesses encounter challenges with technical support when implementing servo solutions, which can lead to downtime and increased costs. Therefore, companies should prioritize manufacturers that provide comprehensive support, including troubleshooting, installation guidance, and regular maintenance.

**Tip:** Before making a purchase, inquire about the availability of technical support during the critical phases of integration. It’s also beneficial to seek testimonials from other users regarding their service experiences to gauge reliability and responsiveness.

Moreover, consider the training resources provided by the manufacturer. A survey by Automation World indicates that 35% of users feel inadequately trained to utilize their linear servo motors effectively. Manufacturers that offer robust training programs can empower your team, minimize errors, and enhance operational efficiency.

**Tip:** Evaluate the depth of training materials available, such as video tutorials, online courses, and user manuals, to ensure that your staff will feel confident in using and maintaining the equipment.

This chart displays the assessment of customer service and support capabilities among different linear servo motor providers based on key factors such as response time, technical expertise, and availability of resources.

When selecting the best linear servo motor for your applications, comparing quotes and product samples is essential to ensure you're making an informed decision. Begin by gathering multiple quotes from various suppliers, paying close attention to key specifications such as torque, speed, and precision. Don't hesitate to ask for detailed breakdowns of costs, including any additional fees for shipping, installation, and support. This transparency will not only help you understand the value of each option but also enable you to negotiate better terms.

Once you've narrowed your choices based on pricing, the next step is to evaluate product samples. Requesting samples allows you to test performance under real-world conditions, providing insight into how each motor will meet your specific application needs. Pay attention to factors like responsiveness, durability, and compatibility with your existing systems. Document the performance of each sample meticulously, as this comparative analysis will guide your final selection. Engaging in this thorough assessment will lead you to a linear servo motor that optimally meets your requirements.