-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

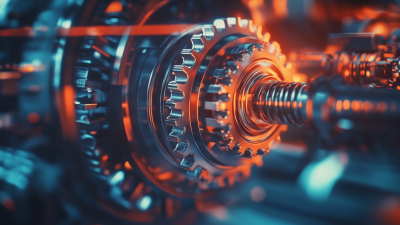

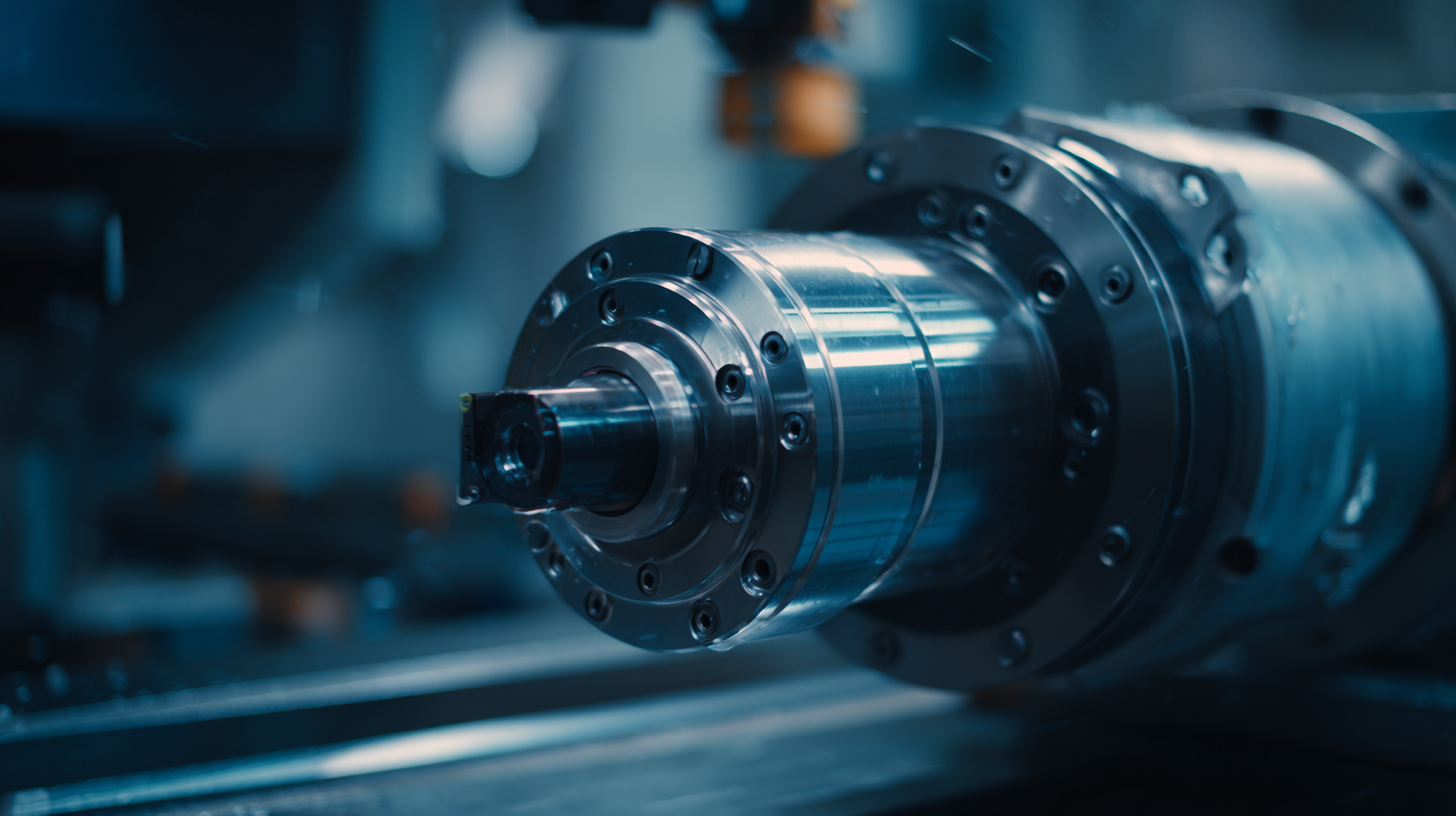

In today's highly competitive manufacturing landscape, the demand for high-performance spindle motors has surged, driven by the need for precision and efficiency in various industries, including automotive, aerospace, and electronics. According to a recent market report by Mordor Intelligence, the global spindle motor market is expected to grow at a compound annual growth rate (CAGR) of over 5% from 2021 to 2026, highlighting the increasing reliance of manufacturers on advanced technologies for optimal performance. High-quality spindle motors are crucial in applications such as CNC machining, milling, and drilling, where precision and reliability are paramount. This guide aims to equip business operators and procurement specialists with essential insights and strategies for sourcing the best spindle motors that meet their specific operational requirements, ensuring they stay ahead in the fast-evolving manufacturing sector.

High performance spindle motors play a crucial role in enhancing productivity and efficiency in various industrial applications. According to a report by Markets and Markets, the global spindle motor market is projected to reach $2.3 billion by 2025, growing at a CAGR of 5.6% from 2020. These motors are pivotal for processes such as CNC machining, where precision and reliability directly influence output quality. Investing in high-performance spindle motors not only improves operational speed but also helps in reducing downtime, ultimately boosting your bottom line.

**Tip 1:** When sourcing spindle motors, consider their energy efficiency ratings. High-performance motors often come with better energy-saving features, which can lead to significant cost reductions in energy bills over time.

Moreover, the selection of the right spindle motor can enhance the lifespan of your machinery. A study by the International Journal of Engineering Research highlighted that using high-quality spindle motors can extend machine life by up to 30%. This longevity reduces the frequency of replacements and maintenance, ensuring your operations remain seamless.

**Tip 2:** Evaluate the torque characteristics of the spindle motors. Choosing motors with the appropriate torque ratings for your applications will not only optimize performance but will also minimize wear and tear on both the motor and your machinery.

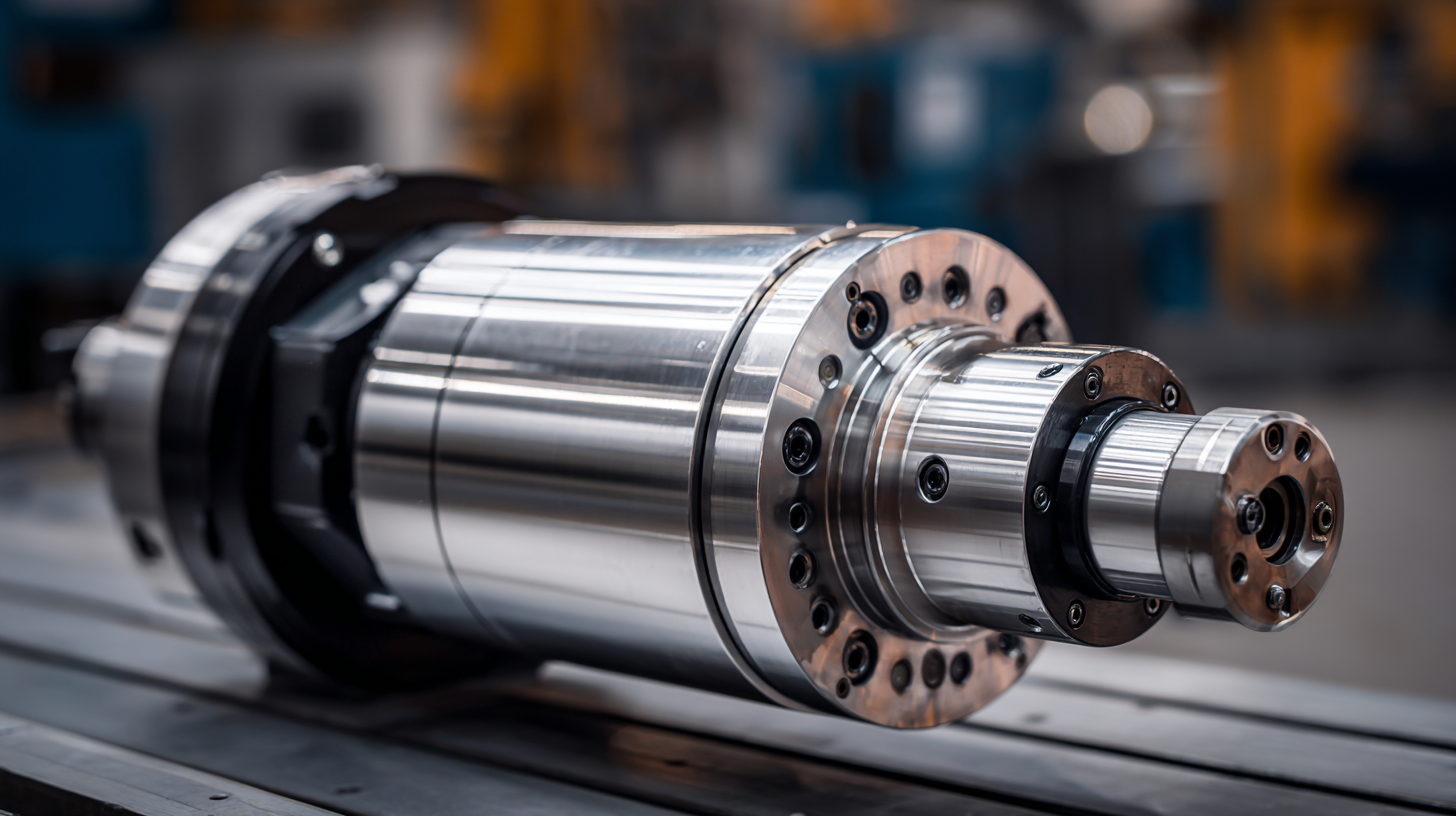

When sourcing high-performance spindle motors for your business, it’s crucial to identify the key specifications that will meet your operational needs. Start by evaluating the motor's power output, as this will determine the performance capabilities of your machinery. High-torque motors can handle heavier workloads, making them ideal for applications requiring precision and efficiency. Another important factor is the spindle speed, typically measured in revolutions per minute (RPM). Higher RPMs allow for faster machining processes, which can lead to enhanced productivity.

Tips: Always check the cooling mechanism of the spindle motor. Efficient cooling is vital for maintaining performance and prolonging the motor's lifespan, especially during continuous operation. Additionally, consider the motor’s compatibility with your existing systems, including voltage requirements and control interfaces. This ensures smoother integration and reduces the chances of operational hiccups.

Another critical feature to assess is the robustness of the motor's construction. A durable spindle motor designed with high-quality materials can withstand the rigors of demanding environments. Look for motors with better protection ratings, such as IP ratings, which indicate resistance to dust and moisture. This can significantly affect the reliability and longevity of the motor in production settings.

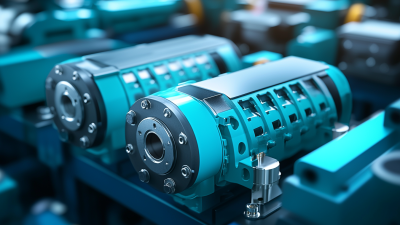

When sourcing high-performance spindle motors, the importance of evaluating top suppliers cannot be overstated. A comprehensive report by MarketsandMarkets indicates that the global spindle motor market is projected to reach USD 9.56 billion by 2025, growing at a CAGR of 5.3%. This growth underscores the necessity for businesses to partner with reliable manufacturers that not only understand industry demands but also deliver quality performance.

Suppliers should be assessed based on their manufacturing processes, compliance with industry standards, and the longevity of their products.

Additionally, testing and customer feedback play pivotal roles in supplier evaluation. According to a study by Research and Markets, around 60% of motor failures are attributed to inadequate quality control during production. This statistic highlights the importance of partnering with suppliers who implement rigorous testing protocols. Engaging with suppliers who prioritize reliability and have a robust supply chain can safeguard your operations and ensure optimal productivity. Thoroughly vetting potential contacts with these considerations will lead to more informed decisions and ultimately contribute to your business's overall success.

When considering whether to invest in high-performance spindle motors or stick with standard models, it's essential to conduct a thorough cost-benefit analysis. High-performance motors often come with a higher upfront cost, but their long-term benefits can significantly outweigh these initial expenses. These motors typically offer improved efficiency, resulting in lower energy consumption and reduced operational costs over time. Additionally, the enhanced durability and reliability of high-performance models can lead to fewer replacements and maintenance interventions, further contributing to overall savings.

Tips: When evaluating your options, consider the specific needs of your operations. Identify tasks that require precision and speed, as high-performance motors can excel in these areas. Additionally, think about your production volume; for businesses with high demands, the investment may pay off much faster than anticipated. Lastly, assess the potential for growth in your operations—if you're planning to scale, a high-performance motor could provide the necessary power without requiring immediate upgrades.

Investing in high-performance spindle motors could also lead to increased productivity. Faster spindle speeds and improved torque can enhance your machine's capabilities, allowing for complex machining tasks to be completed more efficiently. This capability not only improves throughput but can also lead to an expanded range of services offered to clients. Examine your production goals to see how advanced motor technology can help you achieve them, ensuring that the benefits far exceed the costs incurred at the outset.

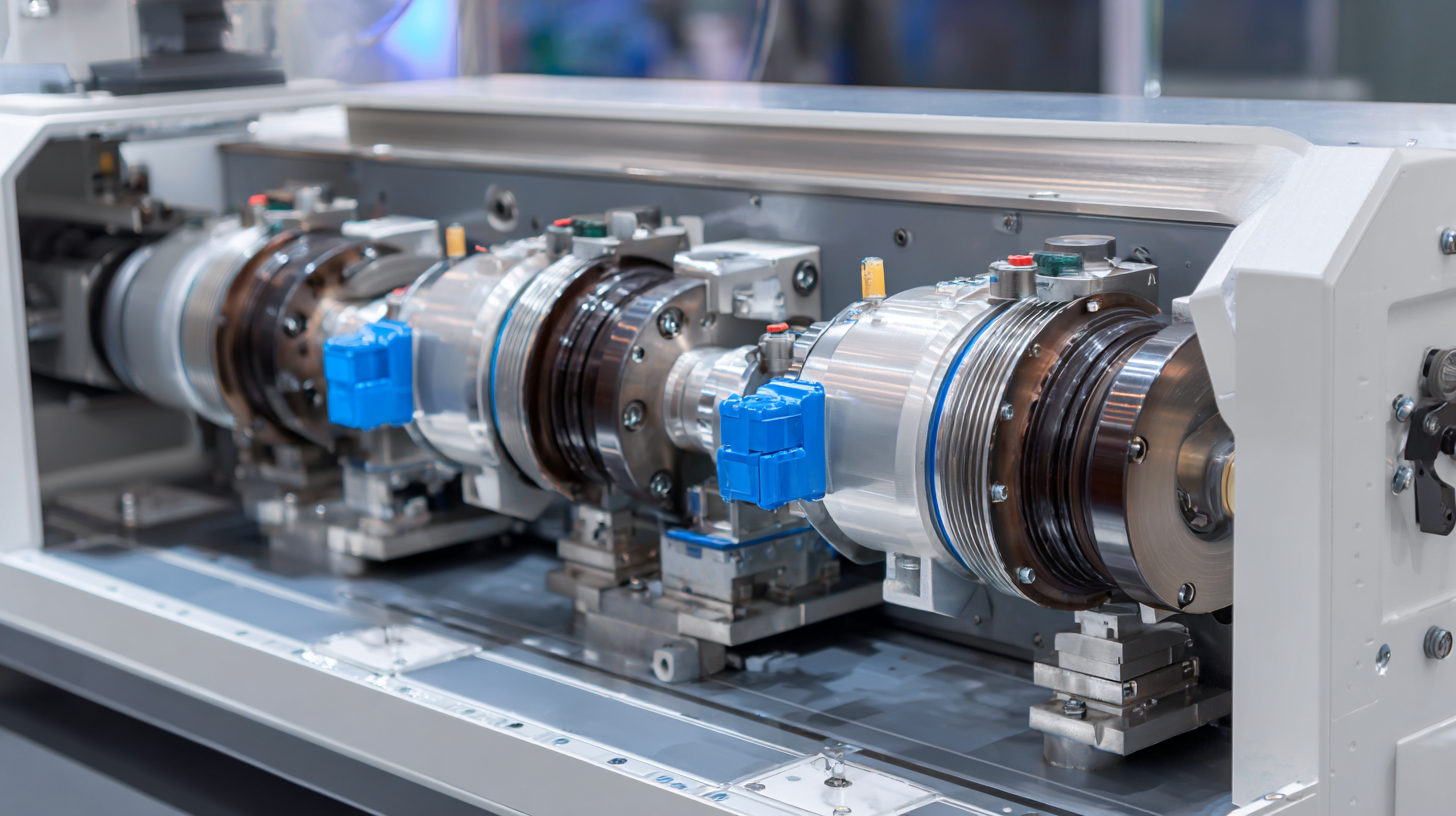

When it comes to spindle motors, efficient performance is key to maximizing production output and reducing downtime. Regular maintenance is the cornerstone of ensuring that your spindle motors operate at peak efficiency. Start by implementing a schedule for routine inspections, which should include checking for signs of wear and tear on bearings, examining coolant levels, and ensuring a clean operating environment free of dust and debris. Proper lubrication is also crucial; using the right type of lubricant at specified intervals can significantly prolong the lifespan of your motors and keep them running smoothly.

Optimization also involves understanding and utilizing advanced monitoring technologies. Employing vibration analysis and thermal imaging can provide insights into potential issues before they escalate, allowing for proactive measures. Moreover, fine-tuning operating parameters, such as adjusting spindle speeds and feed rates according to the specific material and tooling requirements, can enhance both performance and efficiency. By investing in these maintenance and optimization strategies, businesses can achieve their production goals while reducing operational costs and extending the life of their spindle motors.