-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

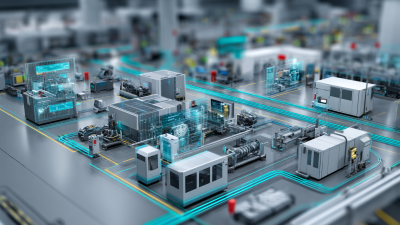

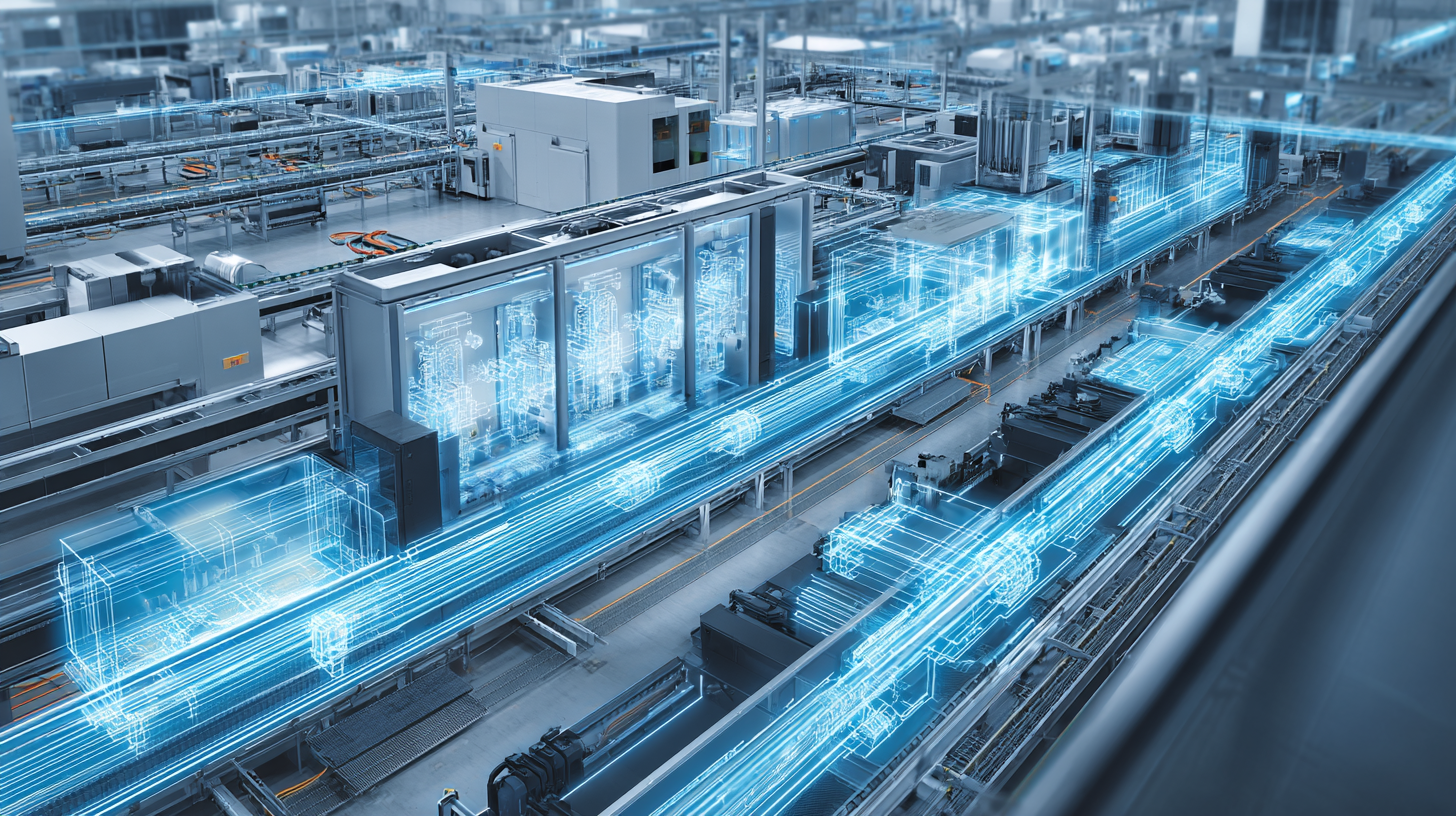

In recent years, the quest for improved energy efficiency in automation systems has led to significant advancements in technology, particularly the integration of Servo Drives. These sophisticated components not only enhance the precision and responsiveness of automated processes but also play a critical role in optimizing energy consumption. According to a report by the International Electrotechnical Commission, implementing Servo Drives can reduce energy use by up to 30% compared to traditional drive systems, thus providing a compelling case for their adoption in modern manufacturing. The 2021 Automation Industry Report indicates that industries deploying Servo Drives are experiencing not only lower operational costs but also a marked improvement in system performance and longevity. As businesses strive to meet sustainability goals and energy regulations, understanding the impact of Servo Drives on energy efficiency has become essential for achieving competitive advantage in the automation landscape.

In recent years, the quest for improved energy efficiency in automation systems has led to significant advancements in technology, particularly the integration of Servo Drives. These sophisticated components not only enhance the precision and responsiveness of automated processes but also play a critical role in optimizing energy consumption. According to a report by the International Electrotechnical Commission, implementing Servo Drives can reduce energy use by up to 30% compared to traditional drive systems, thus providing a compelling case for their adoption in modern manufacturing. The 2021 Automation Industry Report indicates that industries deploying Servo Drives are experiencing not only lower operational costs but also a marked improvement in system performance and longevity. As businesses strive to meet sustainability goals and energy regulations, understanding the impact of Servo Drives on energy efficiency has become essential for achieving competitive advantage in the automation landscape.

Servo drives play a crucial role in modern automation technologies, enhancing the efficiency and precision of various industrial processes. As the integration of automation continues to expand, the demand for servo motors and drives is projected to reach approximately USD 29.22 billion, reflecting the increasing reliance on these technologies across multiple sectors, including automotive and manufacturing. The market for digital servo motors and drives is expected to nearly double by 2035, with estimates indicating growth from USD 9.7 billion in 2025 to USD 18.5 billion. This surge underscores the significant impact that servo drives have on streamlining operations and improving energy efficiency.

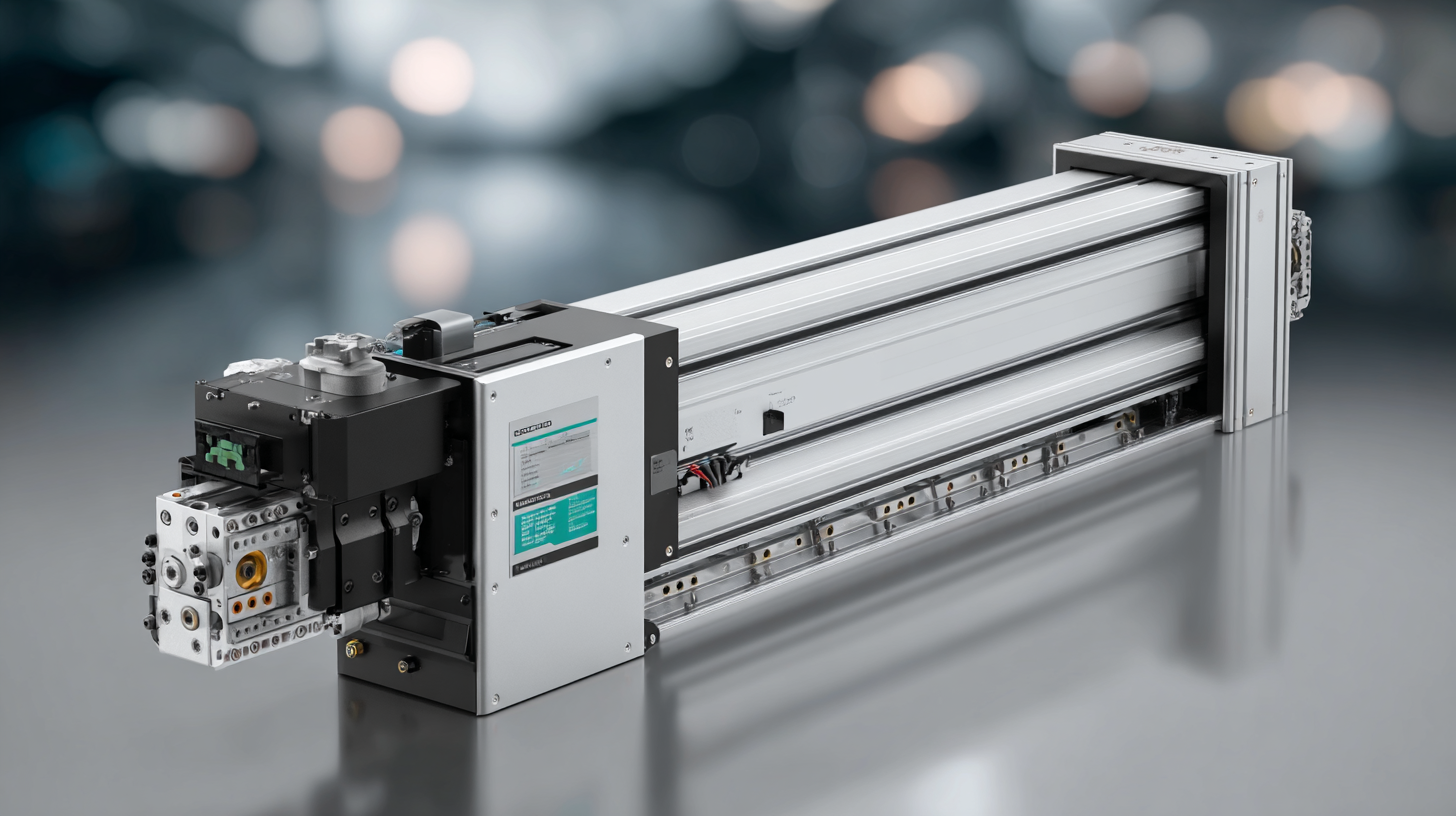

The functionality of servo motors, such as the popular Hf-Kp43 model, contributes to superior motion control capabilities, facilitating enhanced productivity in automated systems. With advancements in servo drive solutions, including high-dynamic systems like the SINAMICS S210, manufacturers are now able to achieve remarkable performance, operating in power ranges from 50 W to 7 kW. Businesses that adopt these cutting-edge technologies, such as servo motors and advanced control systems, can witness substantial improvements in operational efficiency, ultimately leading to greater competitiveness in the evolving industrial landscape.

The energy efficiency of modern automation systems heavily relies on the utilization of servo drives. These innovative technologies offer precise control and enhanced performance, which are essential factors in reducing energy consumption. According to recent industry reports, the global medium voltage drive market is projected to grow significantly, driven by the increasing need for energy-efficient systems across various sectors. Specifically, the adoption of servo drives is expected to climb due to their superior torque control and responsiveness compared to traditional AC and DC drives.

Key factors influencing energy efficiency in servo-driven systems include the optimization of control strategies, the quality of electrical components, and system integration techniques. Research indicates that efficient servo drives can lead to energy savings of up to 30% in automated processes, especially in applications requiring high precision and minimal energy waste. Moreover, as industries face challenges like the shortage of specialized packaging machinery, advancements in servo technology are paving the way for smarter solutions that not only enhance packaging efficiency but also improve thermal insulation capabilities. As a result, integrating these systems within building material packaging has become increasingly pertinent for businesses looking to enhance their operational reliability and performance.

| Key Factor | Impact on Energy Efficiency (%) | Description |

|---|---|---|

| Motor Efficiency | 10-30% | Higher efficiency motors reduce energy loss during operation. |

| Control Algorithms | 15-25% | Advanced algorithms optimize performance and reduce energy consumption. |

| Load Matching | 20-40% | Proper load matching maximizes energy use and minimizes waste. |

| System Design | 10-20% | Efficient design reduces overall energy needs and improves system operability. |

| Feedback Mechanisms | 5-15% | Real-time feedback can adjust operations for better efficiency. |

In the realm of modern automation systems, the choice of drive technology plays a pivotal role in determining energy efficiency. Traditional drive technologies, such as induction motors, often operate with fixed speeds, which can lead to energy waste in applications requiring variable speed control. In contrast, servo drives are designed to provide precise control over motor speeds and positions, enabling more efficient operation across varying load conditions. This capability allows for a significant reduction in energy consumption, especially in applications involving repetitive tasks or complex motion profiles.

In the realm of modern automation systems, the choice of drive technology plays a pivotal role in determining energy efficiency. Traditional drive technologies, such as induction motors, often operate with fixed speeds, which can lead to energy waste in applications requiring variable speed control. In contrast, servo drives are designed to provide precise control over motor speeds and positions, enabling more efficient operation across varying load conditions. This capability allows for a significant reduction in energy consumption, especially in applications involving repetitive tasks or complex motion profiles.

Furthermore, the adaptive nature of servo drives enhances their efficiency relative to traditional alternatives. Unlike fixed-speed systems that may require additional energy for acceleration and deceleration, servo drives adjust their output dynamically based on real-time feedback from the system. This not only improves performance but also minimizes energy losses associated with excess heat generation and idle running. Consequently, the integration of servo drives into automation systems fosters greater sustainability and cost-effectiveness, making them a preferable choice over conventional drive technologies for businesses aiming to optimize their operations.

The optimization of servo drive settings is crucial for enhancing energy efficiency in modern automation systems. By fine-tuning parameters such as torque limits, acceleration rates, and control algorithms, manufacturers can significantly reduce energy consumption without compromising performance. For instance, adjusting the torque limit to align closely with the actual load requirements minimizes unnecessary power usage, resulting in notable energy savings. Furthermore, implementing advanced control strategies, like adaptive or predictive control, enables servo drives to respond dynamically to changing conditions, ensuring they operate only as efficiently as needed.

Moreover, regular maintenance and periodic reevaluation of servo drive settings play a pivotal role in sustaining energy efficiency. As operational environments and requirements evolve, it becomes essential to revisit and adjust the drive settings to maintain optimal performance levels. Utilizing data analytics and monitoring systems can provide insights into operational inefficiencies, helping automate the adjustment process for improved energy savings. Addressing these factors helps not only to lower operational costs but also to contribute to broader sustainability goals within the industry.

The evolution of servo drives is pivotal in shaping the energy landscape of modern automation systems. As technological advancements continue, future trends in servo drive development are expected to significantly enhance energy efficiency. By integrating modular multi-level inverters, servo drives can now convert DC into AC more effectively, reducing energy losses during the conversion process. This innovation aligns with the Clean Power 2030 Action Plan, which emphasizes the need for systems capable of lowering energy costs while simultaneously minimizing carbon footprints across industries.

Furthermore, as the global energy demand surged to nearly double its recent averages in 2024, the importance of energy-efficient technologies such as servo drives becomes even more pronounced. The BSRIA's recent analysis indicates a notable growth in air conditioning systems driven by climate extremes, highlighting the necessity for efficient energy use in temperature control systems. As the demand for energy continues to rise in both emerging and advanced economies, adopting cutting-edge servo drive solutions will play a critical role in achieving sustainability goals and mitigating environmental impacts, ultimately shaping a more efficient energy ecosystem.