-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In today's rapidly evolving industrial landscape, the quest for enhanced efficiency and precision has never been more critical. Industrial Servo Motors are at the forefront of this transformation, driving automation to unprecedented levels of performance. By integrating advanced control mechanisms and responsiveness, these motors are not only streamlining production processes but also achieving an impressive 30% increase in operational efficiency.

This guide will explore how Industrial Servo Motors are revolutionizing various sectors by improving accuracy, reducing energy consumption, and enabling real-time feedback systems. As industries continue to embrace automation, understanding the role of Industrial Servo Motors becomes essential for anyone looking to harness the full potential of modern manufacturing capabilities.

Join us on this journey to unlock the secrets of precision with Industrial Servo Motors and their transformative impact on automation.

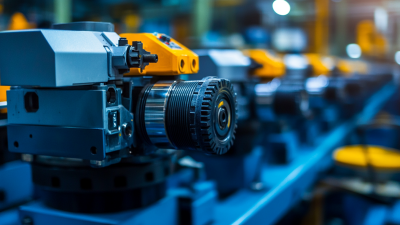

Industrial servo motors have become a cornerstone of modern automation, offering unparalleled precision and efficiency in various applications. These motors work by converting electrical energy into mechanical energy, allowing for controlled motion and position adjustments. Distinct from traditional motors, servo motors can achieve high responsiveness and repeatability, making them ideal for tasks requiring meticulous accuracy, such as in robotics, CNC machinery, and conveyor systems.

Industrial servo motors have become a cornerstone of modern automation, offering unparalleled precision and efficiency in various applications. These motors work by converting electrical energy into mechanical energy, allowing for controlled motion and position adjustments. Distinct from traditional motors, servo motors can achieve high responsiveness and repeatability, making them ideal for tasks requiring meticulous accuracy, such as in robotics, CNC machinery, and conveyor systems.

Tips:

When selecting a servo motor for your automation needs, consider factors like torque requirements, load inertia, and response time. Properly sizing the motor can lead to better performance and energy savings.

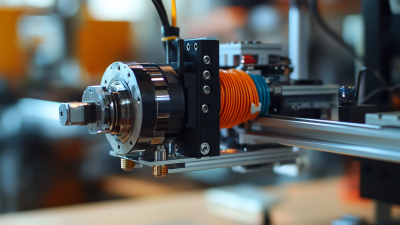

In addition to their performance advantages, industrial servo motors can enhance system integration thanks to their compatibility with advanced automation technologies. Features such as feedback control systems enable machinery to adapt in real-time to changes in load or speed, further optimizing operations. As industries increasingly demand higher efficiency and lower operational costs, understanding the fundamentals of servo motors becomes essential for leveraging their full potential.

Tips:

Ensure that your control system is calibrated to work optimally with your servo motor to maximize efficiency and minimize wear and tear on both the motor and other system components.

As industrial automation continues to evolve, the emphasis on efficiency and precision cannot be overstated. Servo motors are at the forefront of this transformation, offering up to 30% more efficiency in operations compared to traditional motors. This heightened efficiency is largely due to their ability to deliver exact positioning, control speed, and provide real-time feedback to optimize performance. Industries that utilize servo motors benefit not only from reduced energy consumption but also from increased productivity and reduced operational costs.

Tips for Maximizing Efficiency with Servo Motors:

The shift towards energy-efficient solutions is crucial in today’s market, with a notable trend showing that 91% of businesses prioritize energy efficiency when selecting electric motors. By choosing servo motors, organizations can align with these priorities and enhance their industrial operations. This evolution indicates a promising future for companies aiming to boost automation while minimizing their environmental impact.

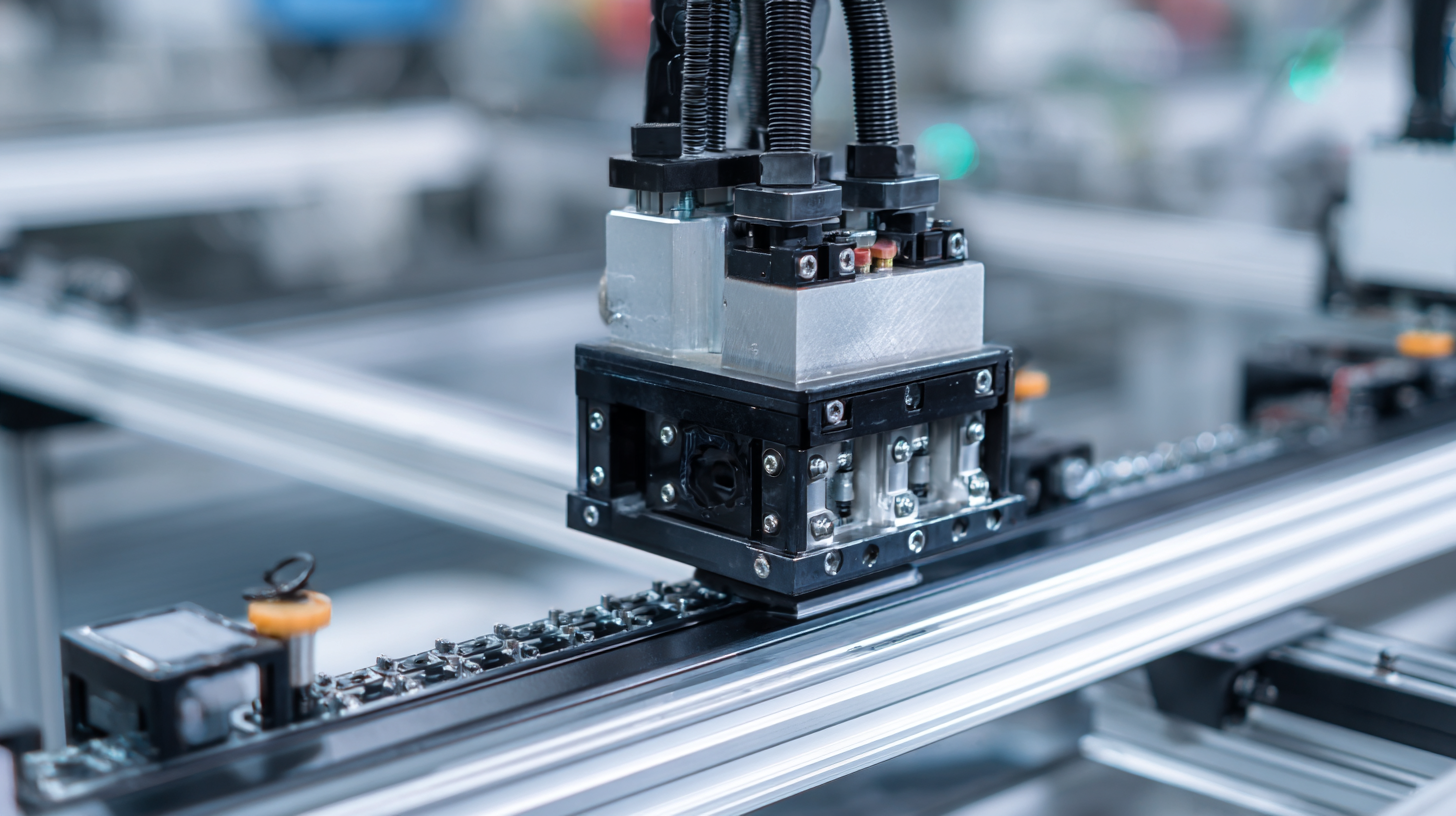

The integration of industrial servo motors is transforming various sectors by enhancing automation processes and achieving significant efficiency gains. In manufacturing, for instance, servo motors are employed in CNC machines, allowing for precise control of cutting tools. This level of accuracy not only improves the quality of finished products but also minimizes material wastage, leading to both cost savings and a lower environmental impact. As a result, manufacturers are able to increase their output without compromising on quality.

In the automotive industry, servo motors are essential in assembly lines where they power robotic arms that perform tasks such as welding and painting. This automation enables rapid production cycles and reduces the potential for human error. Additionally, the adaptability of servo motors allows for quick reprogramming to accommodate design changes, making it easier for automotive manufacturers to keep pace with evolving consumer demands. Overall, the strategic adoption of servo motors across different industries illustrates a pronounced shift towards automation that is not only more efficient but also enhances operational flexibility.

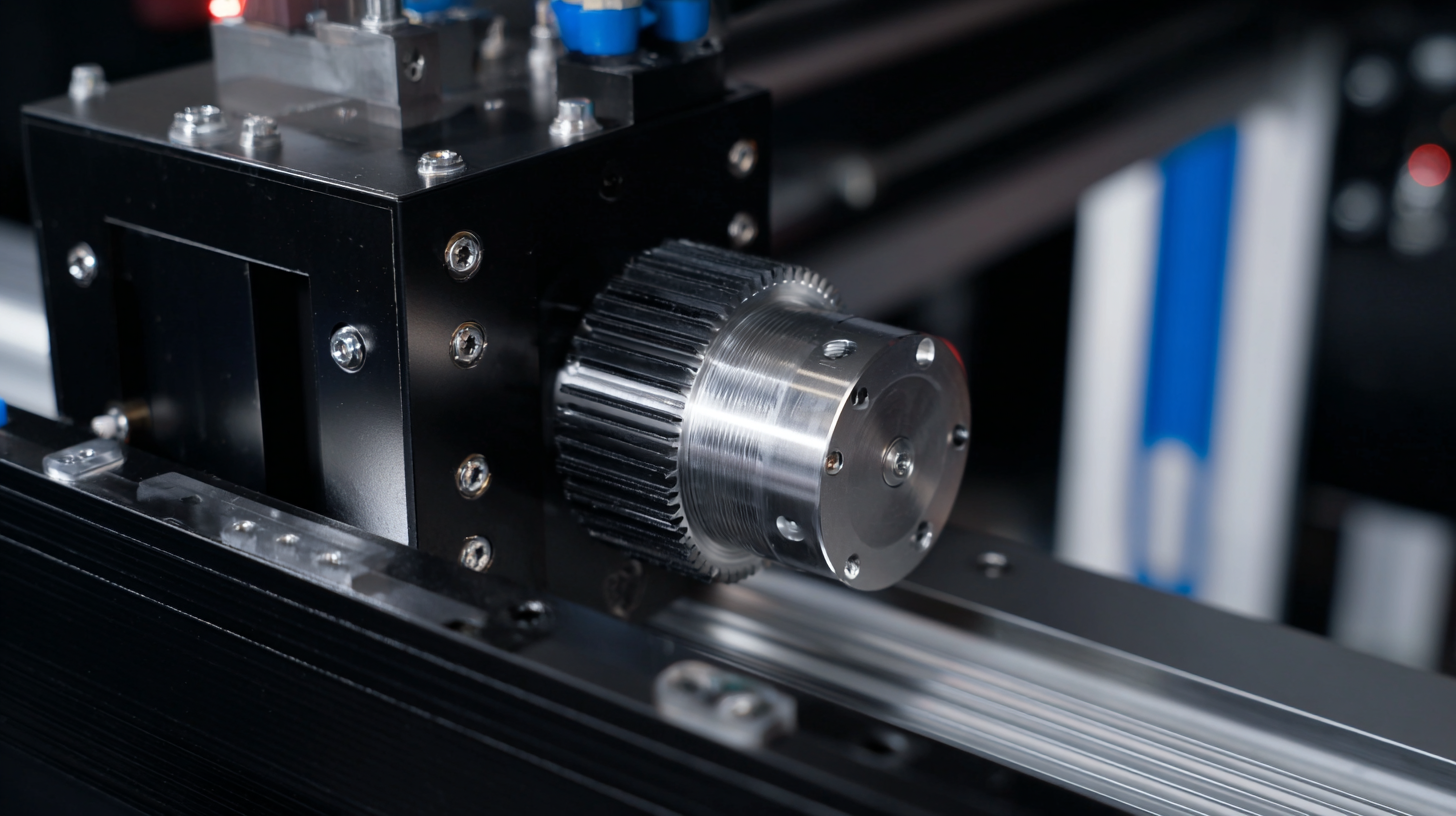

When choosing the right servo motor for your automation needs, it’s crucial to consider several key factors that can significantly impact efficiency and performance. According to a report by machinery manufacturer Siemens, implementing servo motors can enhance automation efficiency by up to 30% compared to traditional motors. This improvement comes from advanced feedback systems that allow for precise positioning and more dynamic control of machinery. Thus, understanding the specific requirements of your application is essential to selecting a motor that will deliver optimal results.

Another critical aspect to consider is the torque and speed characteristics of the servo motor. The International Electrotechnical Commission (IEC) highlights that servo motors provide superior torque at lower speeds, making them ideal for tasks that require both high efficiency and accuracy. Additionally, the compatibility of the servo motor with your existing systems should not be overlooked. Many modern servo motors can be integrated easily with industrial communication protocols, ensuring smooth operation and reduced downtime during installation. By making informed choices based on these factors and industry insights, companies can achieve significant advancements in their automation processes.

| Motor Type | Torque (Nm) | Speed (RPM) | Efficiency (%) | Application |

|---|---|---|---|---|

| AC Servo Motor | 3.2 | 3000 | 90 | Robotics |

| DC Servo Motor | 2.5 | 2500 | 85 | Conveyor Systems |

| Stepper Motor | 1.8 | 2000 | 80 | 3D Printing |

| Brushless Motor | 4.0 | 3500 | 92 | CNC Machining |

The evolution of servo technology is a cornerstone in the advancement of smart manufacturing, significantly impacting areas such as packaging and medical applications. With an emphasis on intelligent sensor technology, manufacturers can achieve a level of automation that enhances precision and efficiency. The integration of mechanical and pneumatic servo systems in the context of plastic sealing machines demonstrates how tailored solutions meet the diverse needs of industries ranging from food and beverage to healthcare.

As factories transition toward smart manufacturing, the functionality of servo motors becomes increasingly vital. The latest trends highlight a shift towards fully automated processes, where smart sensors play a crucial role in real-time monitoring and optimization. This shift not only boosts productivity but also drives improvements in product quality and reduces waste. The ongoing advancements in servo technology indicate a bright future for automated production lines, where efficiency gains of up to 30% are becoming the new standard.

This chart illustrates the efficiency improvement of industrial servo motors in smart manufacturing over the past five years. The data shows a steady increase from 70% in 2018 to a remarkable 100% in 2022, highlighting the transformative impact of servo technology on automation processes.