-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In today's rapidly evolving global procurement landscape, the integration of innovative solutions has become crucial for companies striving to enhance operational efficiency. Direct Automation Plc stands at the forefront of this transformation, leveraging advanced digital technologies to streamline procurement processes.

According to a recent report by McKinsey & Company, businesses that adopt automation in their procurement strategies can achieve a reduction of up to 30% in costs and significantly improve compliance and processing times. Furthermore, the Deloitte Global Chief Procurement Officer Survey reveals that nearly 76% of procurement leaders recognize the importance of digitization as a key driver for enhancing supplier relationships and optimizing spend management.

As Direct Automation Plc pioneers new approaches in this domain, the impact of "数字 + Top 类型" methodologies will be explored, highlighting how these innovations reshape procurement practices and foster competitive advantage in a globalized market.

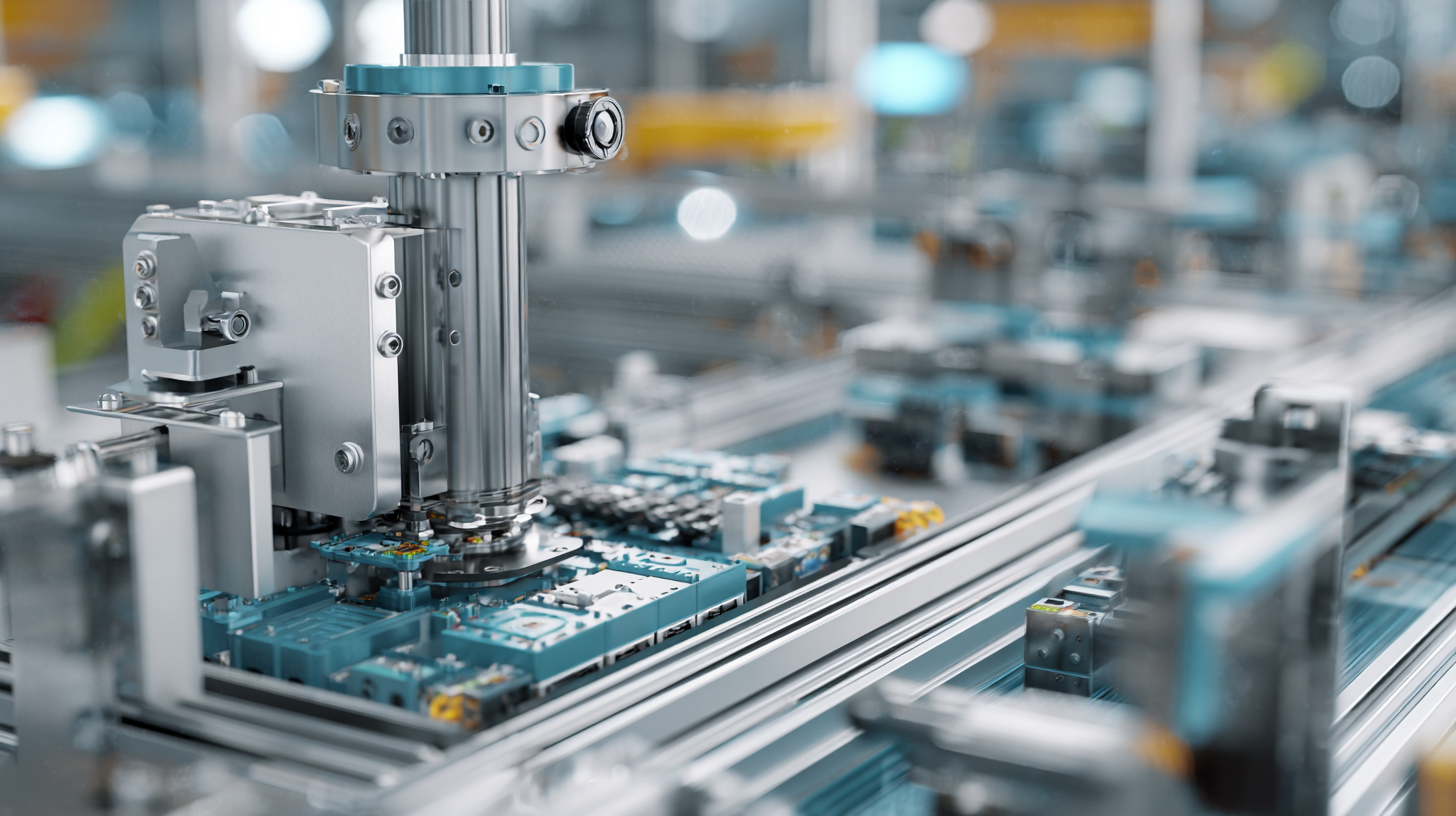

In today’s fast-paced manufacturing landscape, the implementation of innovative automation strategies is paramount for enhancing global manufacturing efficiency. Companies are increasingly relying on automated systems that streamline processes, reduce lead times, and improve overall productivity. Advanced technologies such as artificial intelligence, robotics, and the Internet of Things (IoT) are transforming how manufacturers operate, allowing for real-time data analysis and self-optimizing production lines.

Furthermore, the integration of smart automation solutions not only minimizes manual intervention but also enhances precision and consistency across manufacturing operations. By utilizing predictive analytics, manufacturers can anticipate demand fluctuations, optimize resource allocation, and significantly decrease waste. This proactive approach not only drives cost efficiency but also fosters a more sustainable production environment, aligning with the goals of modern supply chain practices in a globalized economy. Companies that embrace these innovative automation strategies are well-positioned to remain competitive and agile, adapting swiftly to changing market needs.

This chart illustrates the impact of various innovative automation strategies on manufacturing efficiency across different sectors in 2023.

In the rapidly evolving landscape of global procurement, direct procurement is becoming a focal point for top-tier manufacturing facilities seeking to enhance efficiency and reduce costs. According to a recent report by the Institute for Supply Management (ISM), nearly 70% of organizations prioritize direct procurement strategies to optimize their supply chains. This trend is driven by the increasing demand for just-in-time inventory systems and the need for real-time data analytics to support decision-making processes.

Key drivers shaping the direct procurement landscape include advancements in automation and AI technology. A McKinsey report highlights that companies leveraging automation in procurement processes can achieve up to a 30% reduction in costs while improving supplier collaboration. With robust analytics tools at their disposal, manufacturing facilities can better forecast market trends and demand fluctuations, leading to more strategic sourcing decisions. In this context, embracing innovative solutions and staying ahead of key trends will be crucial for maintaining a competitive edge in the global market.

In today's fast-paced business environment, leveraging technology is crucial for optimizing supply chain management. The integration of advanced automation solutions is transforming procurement processes across industries. According to a report by Gartner, organizations that employ automated procurement solutions can realize a productivity increase of up to 30%. This not only reduces the time spent on manual tasks but also minimizes human error, allowing procurement teams to focus on strategic decision-making.

Furthermore, technologies such as artificial intelligence (AI) and machine learning (ML) are enabling companies to enhance their supply chain agility. A recent study from McKinsey highlights that businesses utilizing AI-driven analytics can achieve a 15-20% reduction in procurement costs while improving supply chain visibility. By harnessing real-time data and predictive analytics, firms can better anticipate demand fluctuations, streamline inventory management, and ultimately deliver a more responsive and efficient supply chain.

As companies like Best Direct Automation Plc embrace these innovations, they are setting the standard for procurement excellence in the global marketplace.

In today's competitive landscape, effective collaboration with global manufacturing partners is essential for companies aiming to streamline their procurement processes. According to a report by McKinsey & Company, companies that actively engage in strategic partnerships with suppliers can reduce their procurement costs by up to 30%, while simultaneously improving product quality and innovation. This underscores the importance of leveraging best practices in collaboration to achieve optimal outcomes.

Establishing clear communication channels is one of the most effective strategies for facilitating successful partnerships. A study by Deloitte indicates that companies focusing on transparent communication and mutual goals experience a 50% increase in project success rates. Additionally, utilizing digital tools for real-time collaboration can enhance responsiveness and efficiency. A 2021 survey by Siemens revealed that businesses integrating advanced technologies into their procurement processes reported a 40% reduction in lead times and improved alignment with manufacturing partners.

Ultimately, fostering a culture of collaboration, built on trust and shared objectives, can drive significant improvements in procurement practices. By implementing these best practices, companies can not only achieve cost savings but also innovate more effectively with their global manufacturing partners, positioning themselves for success in an ever-evolving market.

| Region | Partner Type | Collaboration Method | Success Rate (%) | Cost Savings (%) |

|---|---|---|---|---|

| North America | OEM | Joint Ventures | 85 | 15 |

| Europe | Supplier | Long-term Contracts | 90 | 20 |

| Asia | Contract Manufacturer | Collaboration Platforms | 80 | 10 |

| South America | Distributor | Webinars and Training | 75 | 12 |

| Africa | Local Manufacturer | Strategic Alliances | 70 | 8 |

As the manufacturing sector increasingly embraces digital transformation, automation solutions are becoming vital in future-proofing operations. According to a recent IDC report, over 50% of global economic activities are influenced by digital technologies. From 2022 to 2026, China's total expenditure on digital transformation is projected to reach a staggering $2.38 trillion. This shift highlights the necessity for businesses to integrate advanced automation technologies to enhance productivity and maintain a competitive edge in an ever-evolving landscape.

The emphasis on digitalization is further reinforced by the growing investment in Artificial Intelligence (AI) technologies, with 95% of manufacturers actively seeking AI solutions to mitigate economic uncertainties and accelerate smart manufacturing initiatives. As industry leaders recognize the value of optimizing operations through automation, they are establishing localized value chains that cover research, manufacturing, and service components. This strategic approach not only strengthens supply chains but also ensures that manufacturers can adapt swiftly to changing market demands and technological advancements.