-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

As the manufacturing landscape continues to evolve, Mitsubishi Servo Motors have emerged as a pivotal element in enhancing automation and precision in various industries. According to a recent report by MarketsandMarkets, the global servo motor market is expected to grow from USD 8 billion in 2020 to USD 11 billion by 2025, indicating a compound annual growth rate (CAGR) of 8.5%. This growth is driven by the increasing demand for innovative automation solutions and energy-efficient technologies.

The future of Mitsubishi Servo Motors not only lies in their advanced engineering but also in their after-sales service advantages, which play a crucial role in reducing maintenance costs and downtime for manufacturers. As businesses seek to leverage these technological advancements, understanding the emerging trends that shape the future of Mitsubishi Servo Motors becomes vital for remaining competitive in a rapidly changing industrial environment.

The future of servo motors is being shaped by emerging technologies that promise to enhance performance, efficiency, and adaptability across various applications. As we approach 2025, advancements in artificial intelligence, IoT integration, and machine learning are revolutionizing how Mitsubishi servo motors are designed and implemented. These innovations will enable more precise control, better energy management, and improved operational efficiency, catering to the evolving requirements of industries like automotive and manufacturing.

Tips for leveraging these innovations include focusing on automation and real-time data analytics. By integrating predictive maintenance tools, businesses can not only reduce downtime but also optimize the performance of their servo motors, ensuring they operate at maximum efficiency. Additionally, investing in modular servo systems can provide greater flexibility in production processes, allowing for swift adaptations to changing market demands.

Another critical aspect to consider is the growing demand for low voltage drives, anticipated to experience significant growth by 2034. Companies should explore opportunities in this sector, as low voltage solutions become more prevalent in energy-efficient operations. Embracing these cutting-edge trends will position businesses to thrive in the evolving landscape of industrial automation and servo motor technology.

The landscape of Mitsubishi servo motor adoption is rapidly evolving, influenced by various market trends that are reshaping the manufacturing and automation sectors. One significant trend is the increasing demand for energy-efficient solutions. As industries strive to reduce operational costs and adhere to stringent environmental regulations, Mitsubishi servo motors, known for their high efficiency and reliability, are becoming the preferred choice. Companies are increasingly turning to these advanced motors to optimize their energy consumption while maintaining peak performance, making them a go-to solution in sectors ranging from automotive to electronics.

Another driving force is the rise of smart manufacturing and Industry 4.0. The integration of digital technologies and IoT enables more sophisticated control over production processes, enhancing productivity and flexibility. Mitsubishi servo motors are equipped with advanced feedback systems and compatibility with various automation software, allowing for seamless integration into smart factories. This adaptability is key in industries that are embracing digital transformation, as it empowers businesses to implement real-time monitoring and analytics, ultimately leading to better decision-making and efficiency improvements.

| Industry | Adoption Rate (%) | Key Trends Influencing Adoption | Projected Growth (2023-2025) |

|---|---|---|---|

| Manufacturing | 65 | Automation and IoT Integration | 20% |

| Healthcare | 50 | Robotic Surgery Systems | 15% |

| Automotive | 70 | Electric & Autonomous Vehicles | 30% |

| Aerospace | 45 | Improved Flight Control Systems | 10% |

| Food Processing | 55 | Automation of Production Lines | 18% |

In 2025, Mitsubishi servo motors have transformed industrial automation, as showcased in various successful implementations across sectors such as automotive, electronics, and packaging. One notable case study involves a leading automotive manufacturer that integrated Mitsubishi servo motors into their production lines, resulting in a remarkable 30% increase in efficiency and a 25% reduction in energy consumption. According to industry reports, the adoption of advanced servo technology is projected to grow by 15% annually, emphasizing the crucial role these motors play in enhancing operational productivity.

Tips for organizations looking to implement Mitsubishi servo motors include conducting a thorough needs analysis to identify specific performance requirements. Collaborating with experienced system integrators can also provide invaluable insights into optimizing motor configurations for particular applications. Additionally, businesses should consider investing in training for their workforce to ensure they are well-versed in both the technology and its maintenance protocols, enabling them to fully leverage the benefits of these innovative motors.

Another inspiring example comes from the packaging industry, where a company adopted Mitsubishi servo motors for precision control in their packaging machines. This shift not only improved product quality but also reduced waste by 20%, reinforcing the significance of these motors in facilitating sustainability initiatives. Reports indicate that the market for servo motors in packaging is expected to expand by 18%, highlighting the ongoing trend of innovation leading to more efficient and eco-friendly manufacturing processes.

As industries increasingly prioritize sustainability and efficiency, the evolution of servo motor design is poised to reflect these core values by 2025. Reports indicate that the global servo motor market is expected to grow from approximately $11.4 billion in 2020 to around $16.5 billion by 2025, driven by the rising demand for energy-efficient solutions across various sectors. This shift not only emphasizes the need for advanced technology but also highlights the importance of reducing the environmental impact of industrial operations.

The recent strategic partnership aimed at developing ultra-high efficiency gearmotors underscores this trend toward sustainability. By leveraging cutting-edge motor technologies, such as the EM-A series, manufacturers are investing in solutions that significantly enhance operational efficiency while minimizing energy consumption. Data suggests that integrating these advanced motors can lead to energy savings of up to 30%, which supports corporations’ goals of achieving carbon neutrality. As the landscape of industrial drive solutions evolves, the fusion of sustainability and efficiency will be at the forefront of servo motor innovation, shaping the performance and market relevance of these essential components.

This chart illustrates the projected trends in sustainability and efficiency for servo motor designs by 2025, focusing on energy consumption, material sustainability, and technology adoption.

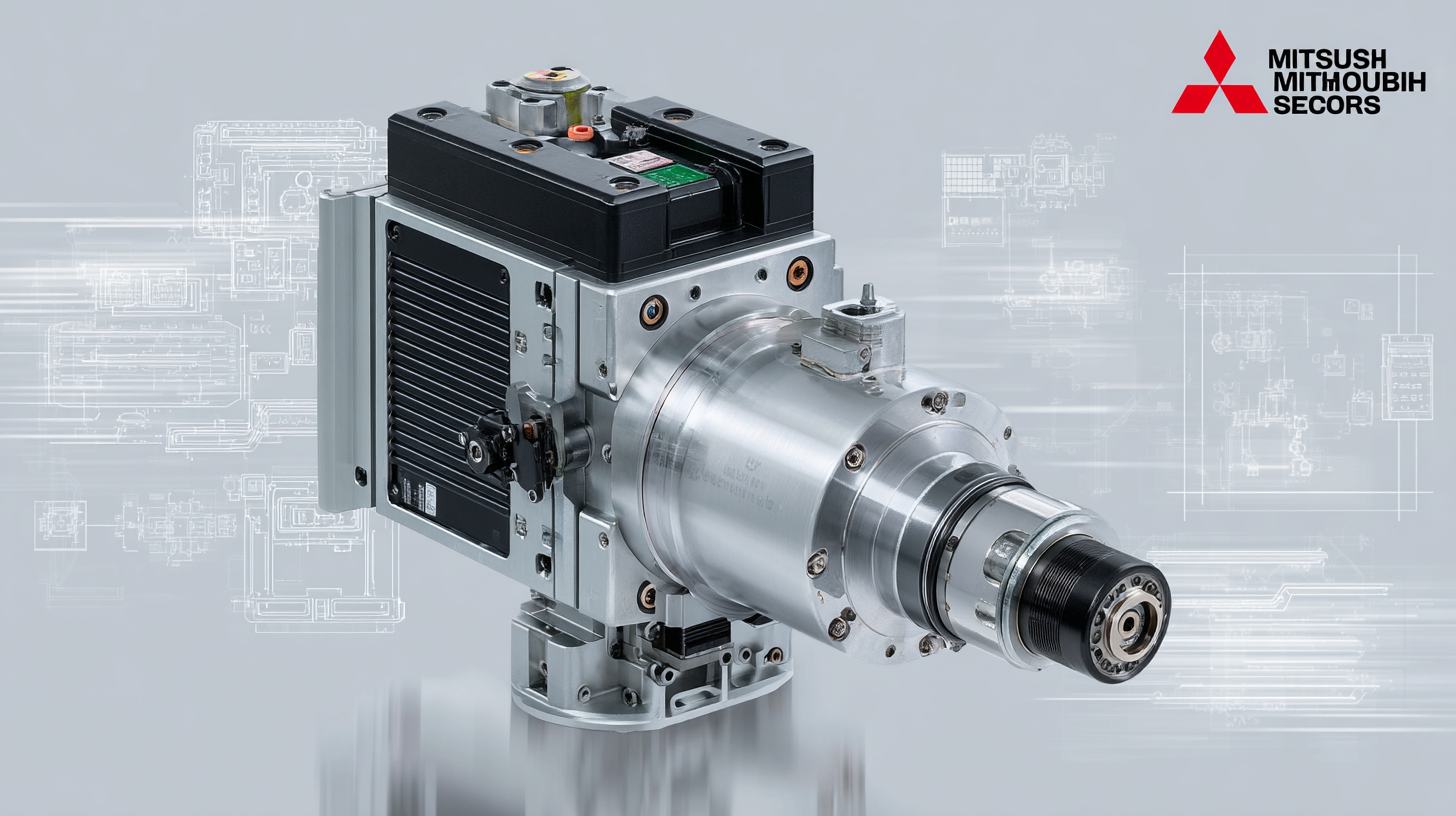

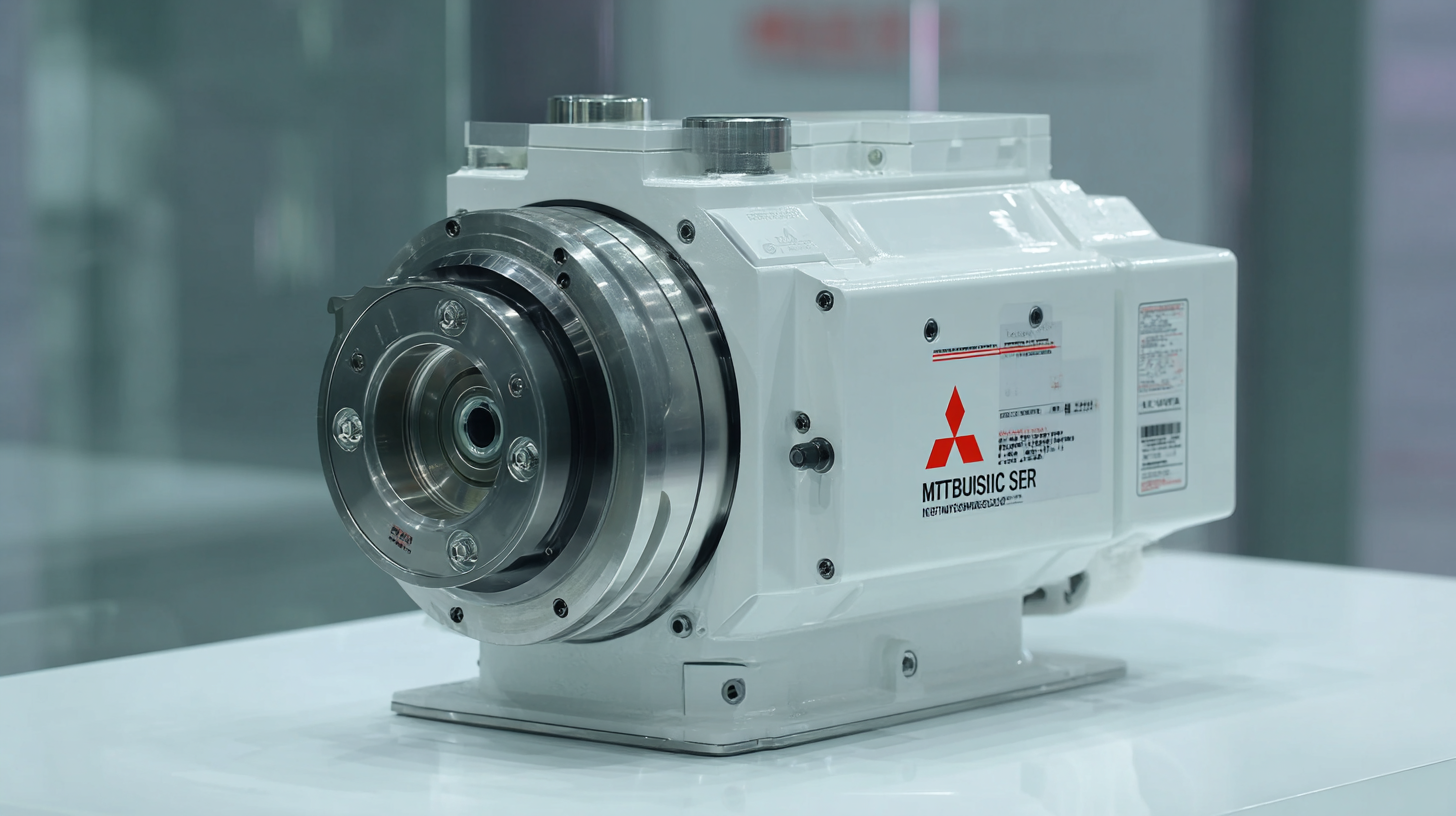

The competitive landscape of the Mitsubishi servo motor market is rapidly evolving, driven by advancements in technology and increasing demand across various sectors. According to a recent industry report, the global servo motors market, which includes Mitsubishi’s offerings, is projected to reach approximately $10 billion by 2025, growing at a CAGR of over 5% from 2020. Key players in this arena, including Siemens, Rockwell Automation, and Yaskawa, are leveraging cutting-edge technologies such as AI and IoT to enhance their product capabilities and create smarter automation solutions.

Mitsubishi Electric, a prominent figure in this market, is focusing on developing high-performance servo motors that integrate seamlessly with modern automation systems. Their latest series of servo motors features advanced feedback control and compact designs that improve efficiency and reduce operational costs. Furthermore, strategic collaborations with other technology innovators are enabling Mitsubishi to expand its market reach and foster innovation. As industries increasingly prioritize sustainability, Mitsubishi’s commitment to producing energy-efficient servos is also likely to give it a competitive edge, making it a significant player in the evolving market landscape.