-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

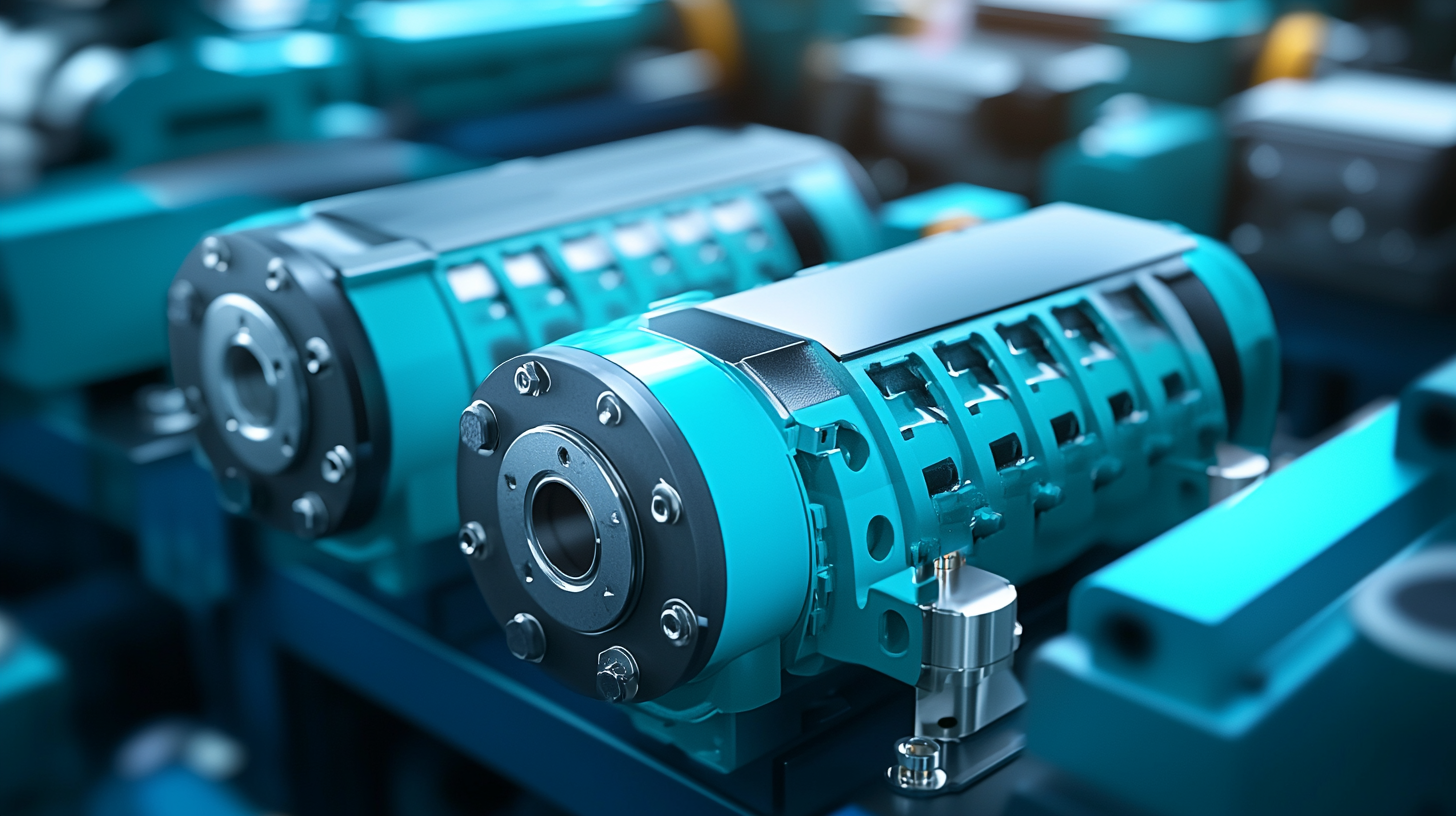

In recent years, the demand for high performance Spindle Motors has surged, driven by the evolving needs of industries such as manufacturing, automotive, and electronics. According to a report by MarketsandMarkets, the global spindle motor market is projected to reach USD 4.9 billion by 2026, growing at a CAGR of 5.9% from 2021. This growth is primarily attributed to the increasing adoption of advanced machining processes and automation technologies, which require precision components that can deliver both speed and torque. As industries strive for enhanced productivity and efficiency, the role of Spindle Motors becomes even more critical. Our commitment to leading the charge in global exports of these essential components reflects our understanding of these trends and our dedication to providing cutting-edge solutions that meet the rigorous demands of today’s market.

The global demand for high performance spindle motors is witnessing an unprecedented surge, attributed to advancements in manufacturing technologies and the increasing need for efficiency in various industrial applications. According to a recent report by ResearchAndMarkets, the spindle motor market is projected to grow at a CAGR of 6.5% from 2023 to 2030, driven by sectors such as automotive, aerospace, and consumer electronics. As manufacturers strive for higher precision and faster operational speeds, the need for reliable spindle motors has never been more critical.

In this competitive landscape, industries are encouraged to consider several key factors when selecting spindle motors. First, evaluate the motor's compatibility with your specific application—whether it requires high torque at low speeds or operates efficiently at higher RPMs. Furthermore, look for motors that offer advanced cooling solutions to enhance performance reliability under sustained operations.

Moreover, investing in quality spindle motors not only improves productivity but also reduces long-term maintenance costs. A comprehensive analysis of your operational needs will guide you in choosing the right motor that aligns with the growing trends of automation and smart manufacturing. Remember, the right spindle motor can significantly impact your overall system performance, so it's worth the effort to research and compare options meticulously.

The chart below illustrates the increasing demand for high-performance spindle motors in global markets over the past five years. The data reflects annual export volumes in thousands of units.

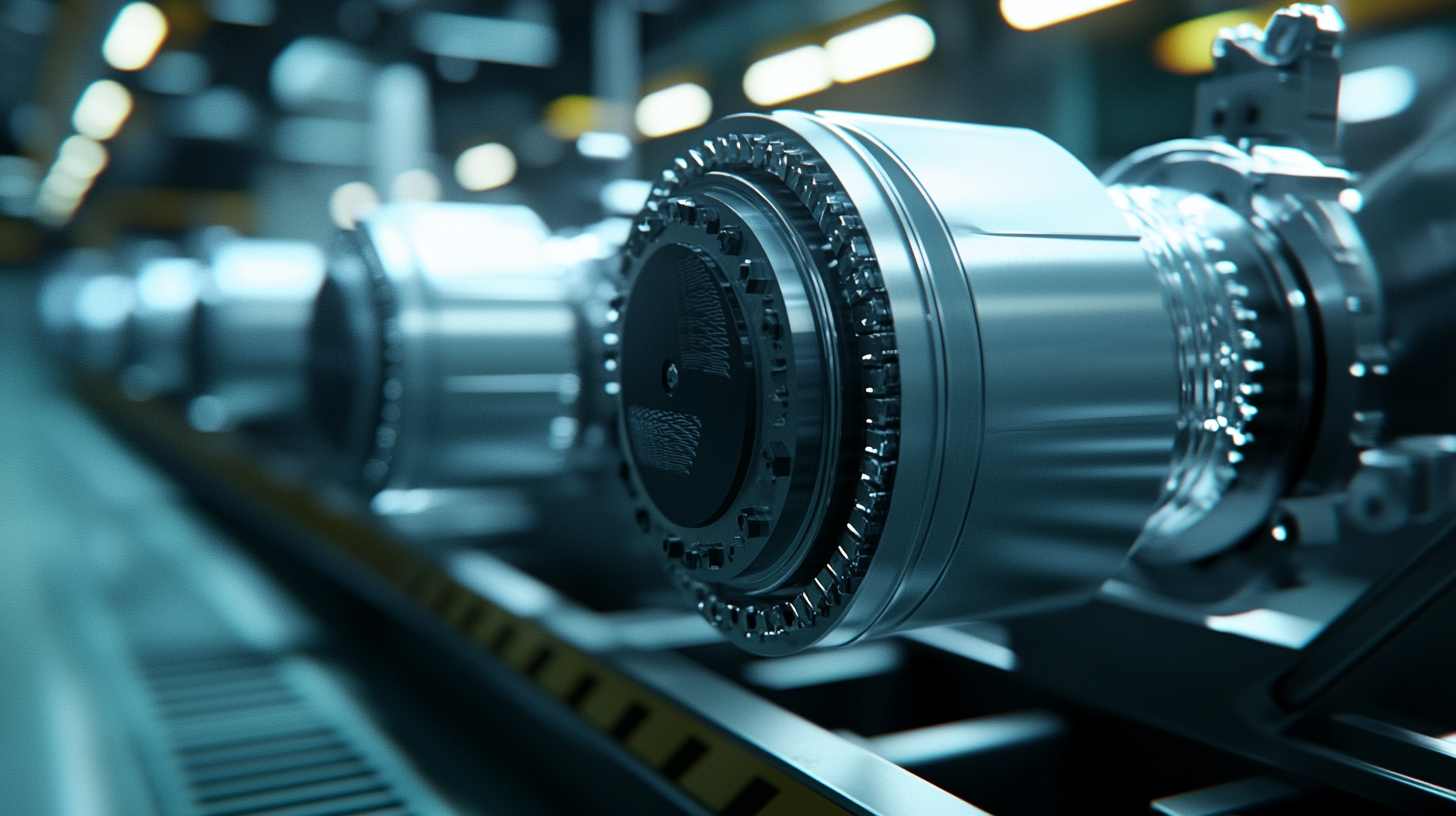

The global market for high-performance spindle motors is rapidly evolving, driven by key players who are setting benchmarks in innovation and competition. Companies like Siemens, Fanuc, and Mitsubishi Electric are at the forefront, continually advancing technology to enhance efficiency and performance. These industry leaders are investing heavily in research and development, focusing on developing smarter, more energy-efficient motors that cater to diverse applications, from CNC machining to automation.

As the demand for precision and reliability in manufacturing processes increases, these key market players are not only enhancing their product offerings but also forging strategic partnerships to expand their global footprint. By leveraging cutting-edge technologies such as IoT and artificial intelligence, they are creating systems that provide real-time data analytics, predictive maintenance, and improved overall functionality. The competition among these innovators is not just about delivering superior products but also about redefining the customer experience in the spindle motor export landscape, ensuring that end-users receive unparalleled value and performance.

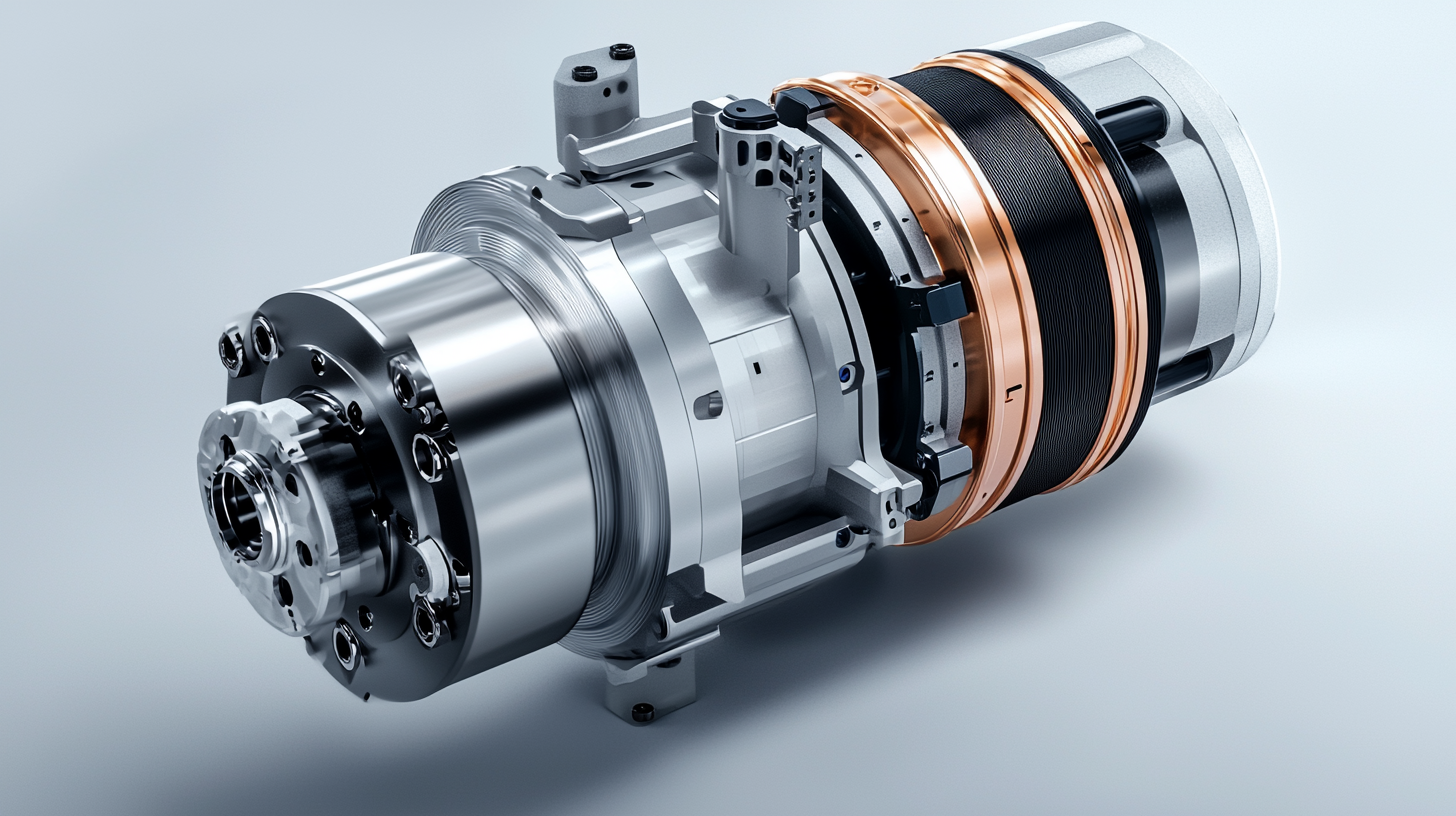

The landscape of spindle motors is undergoing a significant transformation fueled by innovative technological advancements. As the demand for high-performance equipment rises, manufacturers are racing to improve the efficiency and reliability of their spindle motors. According to the latest market analysis by Research and Markets, the global spindle motor market is projected to grow at a compound annual growth rate (CAGR) of 6.3% between 2023 and 2028. This growth is primarily driven by developments in motor control technologies and the integration of smart features that enhance operational performance.

To maximize efficiency, consider leveraging brushless DC (BLDC) motors, which have shown a 20% increase in energy efficiency compared to traditional AC motors. These motors not only reduce operational costs but also minimize energy wastage, thereby promoting sustainability in manufacturing processes. Furthermore, utilizing advanced cooling techniques can enhance the lifespan and performance of spindle motors under heavy workloads. Companies that adopt these cutting-edge solutions stand to lead the charge in global exports, ultimately reshaping industry standards.

It's essential to keep an eye on emerging technologies such as IoT integration and predictive maintenance software. These innovations can dramatically improve the monitoring of spindle motor performance, allowing for real-time diagnostics and preventing potential failure. By embracing these advancements, manufacturers can ensure their spindle motors meet the ever-evolving demands of the market while staying competitive in the global landscape.

The global export landscape for high-performance spindle motors is significantly influenced by trade policies, which can either bolster or hinder growth in this specialized market. According to a report by MarketsandMarkets, the spindle motor market is projected to reach $6.4 billion by 2025, with a compound annual growth rate (CAGR) of 6.6% from 2020 to 2025. This growth is coupled with the ongoing advancements in manufacturing processes and the rising demand for precision machinery across various industries.

Recent trade policies can have far-reaching impacts on both manufacturers and exporters of spindle motors. For instance, tariffs imposed in key markets can increase operational costs and disrupt supply chains, limiting access to vital components. A study by the International Trade Centre noted that countries with favorable trade agreements often witness a 15-20% increase in export volumes compared to those facing trade barriers. As such, adapting to the evolving trade environment is crucial for companies looking to maintain competitive edges in the global market of spindle motors.

This pie chart illustrates the distribution of global exports of high performance spindle motors across various regions. It highlights the impact of trade policies on export volumes.

As we look toward 2030, the spindle motor export industry is poised for transformative growth driven by advancements in technology and increasing demand for high-performance solutions. Leading enterprises are investing in research and development to enhance the efficiency and durability of spindle motors, addressing the needs of various sectors, including automotive, aerospace, and industrial manufacturing. The integration of smart technologies and IoT capabilities is expected to redefine operational standards, providing manufacturers with data-driven insights to optimize performance and longevity.

In addition to technological innovations, global trends indicate a shift toward sustainable practices in manufacturing. As environmental regulations tighten and consumers become more eco-conscious, the focus on energy-efficient spindle motors will likely intensify. Countries that specialize in exporting these cutting-edge products may find themselves at a competitive advantage, capitalizing on a growing market that prioritizes environmental responsibility. The collaboration between manufacturers and governments to foster green technologies is also projected to shape the landscape of the spindle motor export industry, allowing it to thrive in the coming years.