-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

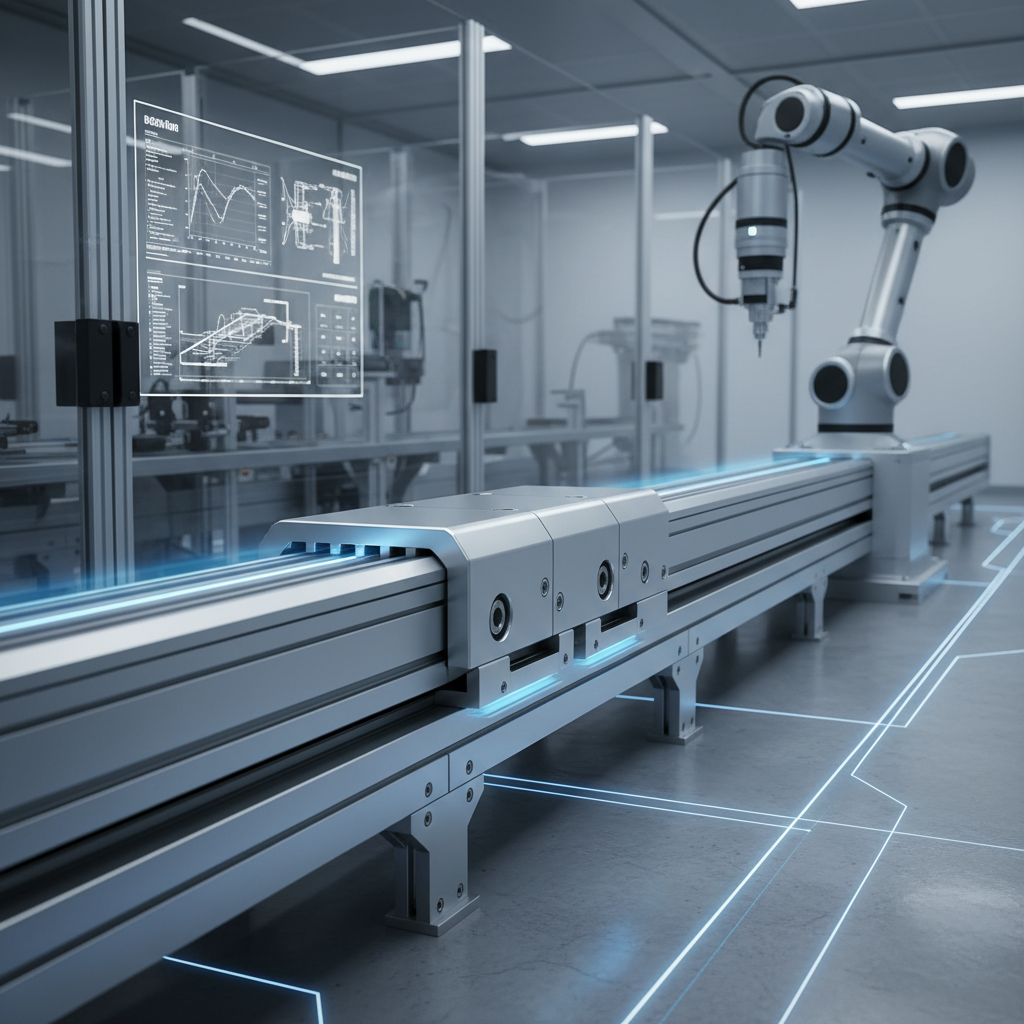

In the ever-evolving field of motion control, Linear Motor Actuators stand out as a transformative technology. As industries increasingly demand precision, speed, and reliability, the linear motor actuator emerges as a crucial component in various applications ranging from robotics to automation. This innovative device converts electrical energy directly into linear motion, eliminating the need for traditional mechanical components like gears and screws, which often introduce inefficiencies and limitations.

The significance of Linear Motor Actuators lies in their ability to provide smooth, consistent, and accurate motion, significantly enhancing operational efficiency. Their design allows for smaller footprints and reduced maintenance needs, making them ideal for modern manufacturing setups and high-performance machinery. Moreover, as the push for automation and advanced robotics intensifies, understanding the functioning and advantages of linear motor actuators becomes essential for engineers and decision-makers looking to optimize their systems.

As we delve into the intricacies of Linear Motor Actuators, we will explore their working principles, key benefits, and the revolutionary impact they have on motion control solutions. By examining real-world applications and advancements in this technology, we can appreciate how linear motor actuators are not just a niche product but rather a driving force behind the future of efficient movement in countless industries.

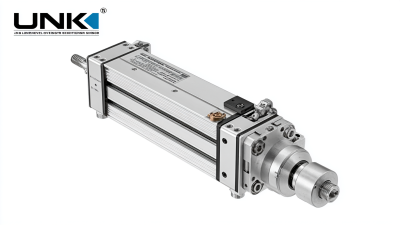

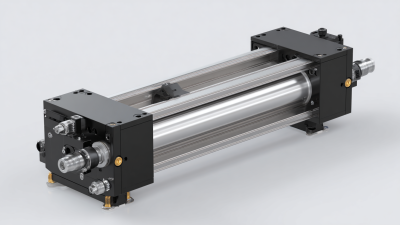

Linear motor actuators are advanced devices that convert electrical energy directly into linear motion, unlike traditional rotary motors that require additional mechanisms to achieve the same result. At the core of their functionality is the principle of electromagnetism, where magnetic fields interact to create force in a straight line. These actuators consist of a stator, which generates magnetic fields, and a moving coil or magnet that is propelled along the stator. This design allows for precise control of movement, high speed, and significant acceleration, making linear motor actuators an exciting choice for various applications.

The versatility of linear motor actuators is evident in their ability to optimize motion control in industries ranging from robotics to manufacturing. By eliminating the need for gears, screws, or belts typically found in traditional systems, they reduce mechanical wear and enhance reliability. Furthermore, their straightforward integration into automated systems allows for seamless implementation in both new and existing setups. As technology advances, the applications for linear motor actuators continue to expand, promising a future where efficient and accurate motion control is the norm.

This chart illustrates the performance of various linear motor actuators in terms of speed, precision, and force output. The data reflects different actuator models and their specifications, showcasing how linear motor actuators can revolutionize motion control.

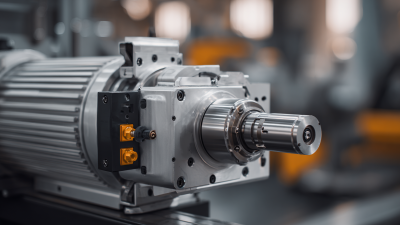

Linear motor actuators are becoming a game-changer in the field of motion control, offering several key advantages over traditional systems. One of the primary benefits is their ability to provide direct linear motion without the need for gears or mechanical linkages, resulting in improved efficiency. This direct drive mechanism allows for faster response times and higher precision, essential for applications that require intricate positioning.

Furthermore, linear motor actuators boast lower maintenance requirements compared to their traditional counterparts. With fewer moving parts, there’s less wear and tear, which translates into reduced downtime and operational costs. Additionally, their compact design enables integration in tight spaces, making them ideal for modern manufacturing environments where space is at a premium. Overall, the advantages of linear motor actuators provide enhanced performance, reliability, and flexibility, making them a superior choice in various motion control applications.

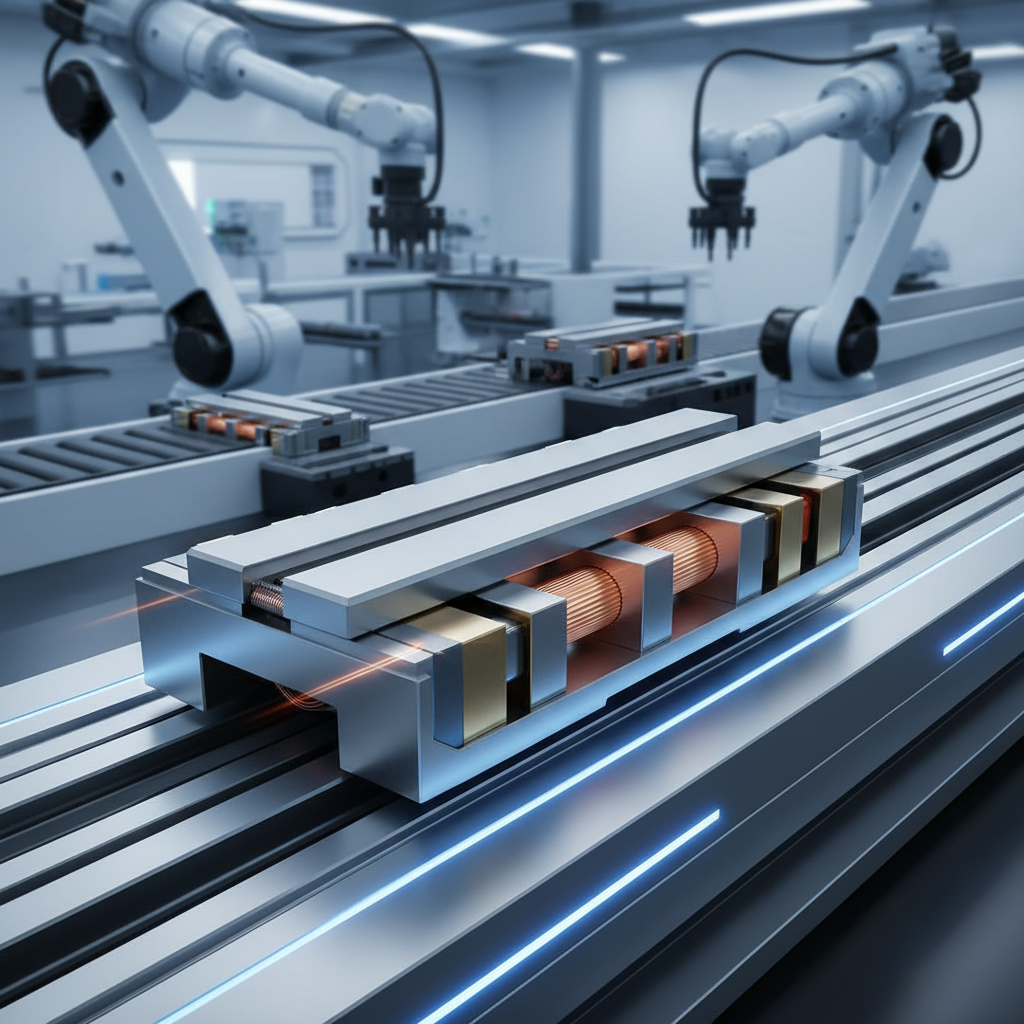

Linear motor actuators are transforming motion control across various industries through their precision and efficiency. In manufacturing, they are used in assembly lines to achieve rapid and accurate positioning of components, significantly enhancing productivity. For instance, automotive assembly employs linear motor actuators for robotic arms that handle parts with remarkable speed and reliability, ensuring consistent quality and reducing downtime.

In the healthcare sector, linear motor actuators find applications in medical devices such as MRI machines and surgical robots. Their capacity for precise movements allows for enhanced imaging and delicate surgical procedures, improving patient outcomes. Additionally, the semiconductor industry benefits from linear motor technology in wafer handling, where precision is critical to the production of electronic components.

Overall, the versatility of linear motor actuators is evident as they revolutionize motion control across these diverse sectors, driving innovation and efficiency.

Linear motor actuators are transforming the landscape of motion control technology, introducing new possibilities for efficiency and precision. As industries move toward automation, advancements in linear motion control are becoming essential. Future trends indicate a shift towards smarter systems, integrating IoT connectivity and advanced algorithms to enhance responsiveness and adaptability. This fusion of technology allows for predictive maintenance and real-time adjustments, optimizing performance and reducing downtime.

Tips for integrating linear motor actuators into your system include assessing the specific requirements of your application to select the appropriate motor type. Pay attention to the compatibility of components, ensuring they work seamlessly together to achieve desired outcomes. Additionally, considering a modular design can facilitate easier upgrades and maintenance, keeping your systems at the forefront of technology.

Moreover, innovations such as AI-driven control systems and energy-efficient designs are set to revolutionize linear motion control further. Companies are exploring lightweight materials and advanced fabrication techniques that reduce costs and improve overall system capabilities. Embracing these trends not only enhances performance but also ensures adaptability in the rapidly evolving industrial landscape.

Linear motor actuators are transformative components in automation and robotics, offering precise motion control and eliminating the need for traditional mechanical systems. These actuators convert electrical energy directly into linear motion, resulting in faster response times and reduced maintenance requirements.

Their integration into robotic systems enhances efficiency and accuracy, making them ideal for applications ranging from assembly lines to advanced robotic arms.

Tips: When considering the adoption of linear motor actuators in your automation projects, evaluate the specific motion requirements and load capacities. Understanding the unique characteristics of your application can help you choose the right actuator type for optimal performance.

Moreover, the impact of linear motor actuators extends beyond just speed and precision. Their compact design allows for innovative robotic configurations that can fit into tighter spaces, opening up new possibilities in design and functionality.

As industries move towards more automated solutions, the implementation of linear motor actuators will be crucial in staying ahead of the competition while maximizing productivity.