-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

The integration of Delta Servo Motors into automation systems has become paramount for industries seeking to enhance operational efficiency and precision. According to a recent report by Markets and Markets, the global servo motor market is expected to reach $10 billion by 2025, driven by the demand for high-performance automation solutions across various sectors. Delta Servo Motors, known for their superior control, reliability, and energy efficiency, play a crucial role in achieving optimal performance in these automation systems. With an increasing emphasis on smart manufacturing and Industry 4.0 principles, mastering the integration of Delta Servo Motors not only facilitates improved precision but also significantly reduces downtime and operational costs. As we delve into this guide, we will explore essential strategies and best practices to effectively integrate Delta Servo Motors, enabling businesses to leverage their full potential in modern automation applications.

Delta servo motors play a crucial role in enhancing automation systems, providing precision, torque, and efficiency that meet the diverse needs of various industries. As the servo driver market is projected to surge from $6.72 billion in 2019 to $12.82 billion by 2032, with a compound annual growth rate of 6.47%, the importance of mastering their integration becomes paramount. Understanding the fundamental principles of Delta servo motors, including their functionality and operational characteristics, is essential for optimizing performance in automation applications.

Delta servo motors play a crucial role in enhancing automation systems, providing precision, torque, and efficiency that meet the diverse needs of various industries. As the servo driver market is projected to surge from $6.72 billion in 2019 to $12.82 billion by 2032, with a compound annual growth rate of 6.47%, the importance of mastering their integration becomes paramount. Understanding the fundamental principles of Delta servo motors, including their functionality and operational characteristics, is essential for optimizing performance in automation applications.

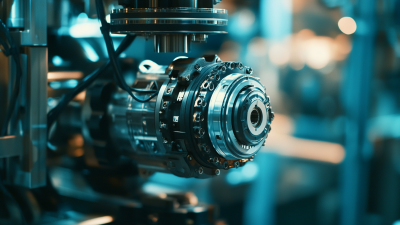

One major innovation is the development of high-torque, ultra-compact servo motors with integrated gearing systems, which simplify installations and improve performance. For instance, recent advancements in miniaturized linear servo motors with built-in encoders and temperature sensors demonstrate how technology is evolving to meet the growing demands for compact and responsive automation solutions.

Tips for Integration: Always ensure proper alignment during installation to prevent excess wear and tear. Regularly updating the control software can enhance the performance and functionalities of servo motors. Furthermore, consider utilizing multiprotocol servo drive kits, which provide flexibility and ease in learning for engineers and programmers, paving the way for more efficient automation strategies.

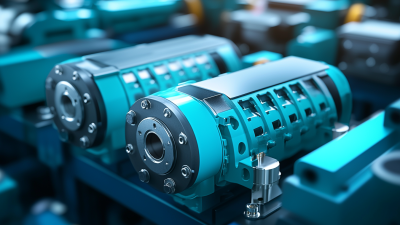

Integrating Delta servo motors into industrial automation systems provides significant advantages that enhance operational efficiency and productivity. These motors are known for their precision and responsiveness, making them ideal for applications requiring high accuracy and speed. By implementing Delta servo motors, manufacturers can achieve smoother motion control and reduce cycle times, thereby improving overall throughput. The seamless integration of these motors within existing systems allows for better control of processes, leading to fewer errors and increased reliability in production environments.

Moreover, the advanced capabilities of Delta servo motors contribute to energy savings and cost reductions. With their high torque-to-weight ratio and optimal energy consumption, businesses can lower operational costs while maintaining performance standards. In an era where automation continues to dominate the industrial landscape, integrating Delta servo motors positions companies to leverage cutting-edge technology while ensuring flexibility and adaptability in their operations. This strategic move not only enhances current workflows but also prepares organizations to meet the evolving demands of the market.

When integrating Delta servo motors into automation systems, following best practices can significantly enhance their performance. First and foremost, proper configuration is critical. Ensuring that parameters such as torque, speed, and acceleration are fine-tuned to match the specific application will lead to optimal motor responsiveness and efficiency. This aspect is akin to adjusting system settings in demanding applications like data processing, where precise tweaks can maximize performance.

Moreover, regular maintenance and monitoring are essential for sustained performance. Implementing real-time monitoring systems allows for the identification of potential issues before they escalate. This is similar to optimizing settings in data-heavy environments to ensure reliable performance. Additionally, leveraging simulation tools to model the servo motor's behavior under various conditions can provide insights that lead to improved integration strategies. By adhering to these best practices, companies can unlock the full potential of Delta servo motors, ensuring their automation systems run smoothly and efficiently.

Integrating delta servo motors into automation systems can significantly enhance performance and efficiency. However, engineers often face common challenges during this process. One of the primary hurdles is achieving precise communication between the servo motor and the controller. According to a report from Industry Week, nearly 30% of automation professionals cited poor communication protocols as a leading cause of integration failure. Ensuring that the integration supports standard communication interfaces like EtherCAT or CANopen can greatly improve reliability and ease of troubleshooting.

Another challenge is the proper tuning of the servo motors, which can impact system responsiveness and precision. Research from the International Society of Automation indicates that improper tuning can lead to a 20-30% decrease in operational efficiency. To overcome this, using advanced tuning software that can simulate performance under various load conditions is crucial. Furthermore, incorporating feedback systems such as encoders helps in maintaining optimal performance levels, allowing for real-time adjustments that can prevent deviations in automation tasks. By addressing these challenges with targeted strategies, businesses can fully leverage the capabilities of delta servo motors in their automation systems.

The integration of Delta Servo Motors into automation systems has proven to deliver remarkable performance enhancements across various industries. Real-world case studies highlight these advancements, showing that companies implementing Delta Servo solutions have reported efficiency increases of up to 30%. For instance, a manufacturing plant that adopted Delta Servo Motors for its assembly line observed a dramatic reduction in cycle times, allowing for a 25% boost in overall productivity. According to a report by the International Society of Automation, utilizing precision servos can enhance motion control accuracy by 40%, significantly reducing waste and increasing throughput.

When considering Delta Servo Motor integration, it's crucial to assess the specific needs of your automation system. **Tip:** Conduct a thorough analysis of your current processes to identify bottlenecks that could be alleviated by servo technology. Additionally, consulting with experts can help tailor a solution that maximizes ROI.

Another successful case is in the packaging industry, where Delta Servo Motors were deployed to optimize motion dynamics for faster packaging rates. This implementation not only improved speed but also minimized operational costs, with some companies reporting savings of up to 15% in energy consumption. **Tip:** Monitor performance metrics regularly post-deployment to ensure the system adapts and maintains optimal functionality. With the right application, Delta Servo Motors can significantly enhance system efficiency and productivity.

| Case Study | Industry | Challenges | Solutions | Results |

|---|---|---|---|---|

| Automated Packaging Line | Food & Beverage | Slow throughput and misalignment | Integrated Delta servo motors with precise alignment systems | Increased throughput by 30% with reduced waste |

| High-speed Sorting System | Logistics | Inaccurate sorting and delays | Implemented advanced feedback control with Delta servo motors | Improved sorting accuracy to 99.5% with time savings of 20% |

| Automated Assembly Line | Electronics | Frequent breakdowns and maintenance | Switched to high-durability Delta servo motors with predictive maintenance | Reduced downtime by 40% and extended equipment lifespan |

| CNC Machining Center | Manufacturing | Precision issues leading to rework | Upgraded to Delta servo motors with enhanced precision controls | Achieved tolerances within ±0.01 mm, reducing rework by 50% |