-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In today's rapidly evolving industrial landscape, maximizing the efficiency of servo motor drives is paramount to maintaining a competitive edge. According to a recent report by the International Society of Automation (ISA), effectively optimizing servo motor drives can lead to energy savings of up to 30% and significantly enhance overall system performance. As industries increasingly adopt automation and robotics, the demand for high-performance servo motor drives continues to surge, projected to reach a market value of over $14 billion by 2025, as indicated by a comprehensive analysis from Research and Markets. This ultimate guide delves into the top strategies for optimizing your servo motor drive performance, ensuring that you harness the full potential of these critical components in your automation systems.

When setting up your servo motor drive for optimal performance, conducting essential pre-installation checks is crucial.

These checks ensure that all components are compatible and functioning properly before you begin the installation process.

One of the first steps is to verify the specifications of the servo motor and the drive. Make sure that

voltage, current ratings, and other parameters match to avoid any potential issues that can arise from mismatched components.

Tip 1: Before installation, inspect all wiring and connections.

Ensure that there are no damaged cables and that all connectors are secure. Loose or frayed wires can lead to performance issues and even cause damage to the motor or drive during operation.

Tip 2: Additionally, it's important to check the environmental conditions where the servo motor will be installed.

Factors like temperature, humidity, and exposure to contaminants can significantly affect performance.

Make sure your installation area meets the recommended specifications for the servo motor and drive to guarantee optimum operational efficiency.

By paying close attention to these pre-installation checks,

you can significantly enhance the performance and reliability of your servo motor drive system.

When it comes to optimizing servo motor drive performance, key parameter adjustments can significantly enhance output and reliability. One of the foremost parameters to consider is the PID controller settings, which dictate how the servo responds to deviations from the setpoint. Tuning the proportional, integral, and derivative gains can help achieve a balance between responsiveness and stability, reducing overshoot and settling time, which is crucial in high-precision applications.

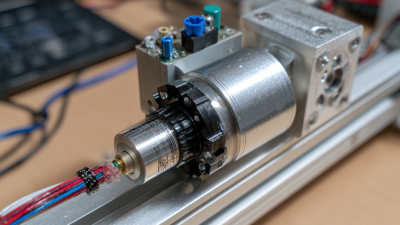

Another critical parameter is the current limit setting. By adjusting this limit, you can optimize the torque output without risking overheating or damaging the motor. This adjustment is essential for applications that require varying degrees of load, as it allows for efficient operation across different scenarios. Additionally, verifying the encoder feedback settings ensures accurate position and speed control, further enhancing overall performance. These careful adjustments not only improve the servo's operational efficiency but also extend its lifespan, guaranteeing that your system performs at its best in demanding environments.

Preventive maintenance is crucial for maximizing the lifespan and performance of your servo motor drive. Regularly scheduled inspections should top your maintenance checklist, allowing you to identify wear and tear before they develop into significant issues. Check for signs of overheating, unusual noises, or vibrations, as these can indicate underlying problems that could compromise your drive’s efficiency. Moreover, keeping an eye on connectors and cables can prevent electrical faults that might lead to costly downtime.

Lubrication is another key component of effective maintenance. Ensure that the bearings and mechanical components of the servo motor are adequately lubricated according to the manufacturer's guidelines. This not only reduces friction but also helps in dissipating heat, thereby preventing premature wear. Additionally, periodic cleaning of the drive and surrounding areas is essential to avoid dust accumulation that can impair cooling functions. Implementing these preventive measures can foster a longer and more reliable performance from your servo motor drive, ultimately leading to improved productivity in your operations.

When working with servo motors, troubleshooting common issues is crucial for maintaining optimal performance. One frequent problem is poor responsiveness, which can stem from incorrect tuning of the servo drive parameters. To address this, start by checking the gain settings. Adjusting the proportional, integral, and derivative (PID) values can improve the system's reaction to changes in input, thus enhancing overall performance.

Another challenge is overheating, often caused by insufficient cooling or excessive load on the motor. Ensuring adequate ventilation in the operating environment can significantly reduce the risk of overheating. Additionally, monitoring the load and making necessary adjustments to prevent overloading will help sustain the motor’s lifespan. Regularly checking the motor for wear and tear and replacing any damaged components promptly can also prevent performance degradation, making your servo system more reliable and efficient.

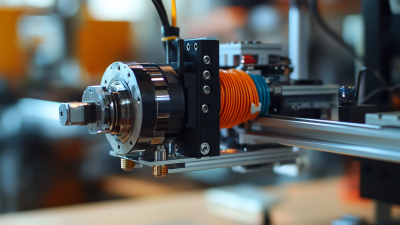

Integrating servo motor systems effectively requires a keen understanding of both the mechanical and electronic components involved. One of the best practices is to ensure proper alignment and mounting of the servo motors to minimize wear and improve performance. Misalignment can lead to excess friction and heat generation, ultimately affecting the lifespan of the motor. Utilizing precision alignment tools during assembly can help achieve optimal positioning, ensuring that the servo motor operates efficiently.

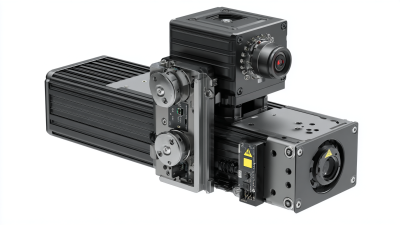

Another critical aspect of effective system integration is the selection of appropriate communication protocols. Compatibility between the servo drive and the control system is essential for precise command execution and feedback. Employing protocols such as CANopen or EtherCAT can facilitate faster data exchange and enhance real-time communication, leading to improved responsiveness and accuracy in motion control. Understanding these protocols and selecting the right one for your application can significantly boost system performance and reliability.

Finally, regular maintenance and calibration play a vital role in sustaining optimal performance over time. Implementing a routine inspection schedule to check for wear on gears, belts, and other components will help identify issues before they escalate, reducing downtime. Additionally, recalibrating the system after significant changes or upgrades can ensure that the servo motor maintains its accuracy and efficiency, ultimately enhancing overall system performance.

| Strategy | Description | Benefits | Implementation Tips |

|---|---|---|---|

| Tuning Control Parameters | Adjusting proportional, integral, and derivative gains for optimal control. | Improved responsiveness and stability of the motor. | Use simulation tools to test different settings before applying them. |

| Regular Maintenance Checks | Routine inspections and servicing of servo motors. | Reduced downtime and prolonged motor life. | Create a maintenance schedule and log service activities. |

| Use of Feedback Sensors | Implementing sensors to provide real-time feedback on motor performance. | Enhanced precision and control of motion. | Select appropriate sensors based on application requirements. |

| Choosing the Right Drive | Selecting a servo drive that matches motor specifications. | Better compatibility and optimized performance. | Consult technical datasheets for gear ratios and load capacities. |

| Electrical Noise Reduction | Minimizing electrical interference that can affect motor performance. | Improved signal integrity and system performance. | Use shielded cables and proper grounding techniques. |