-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

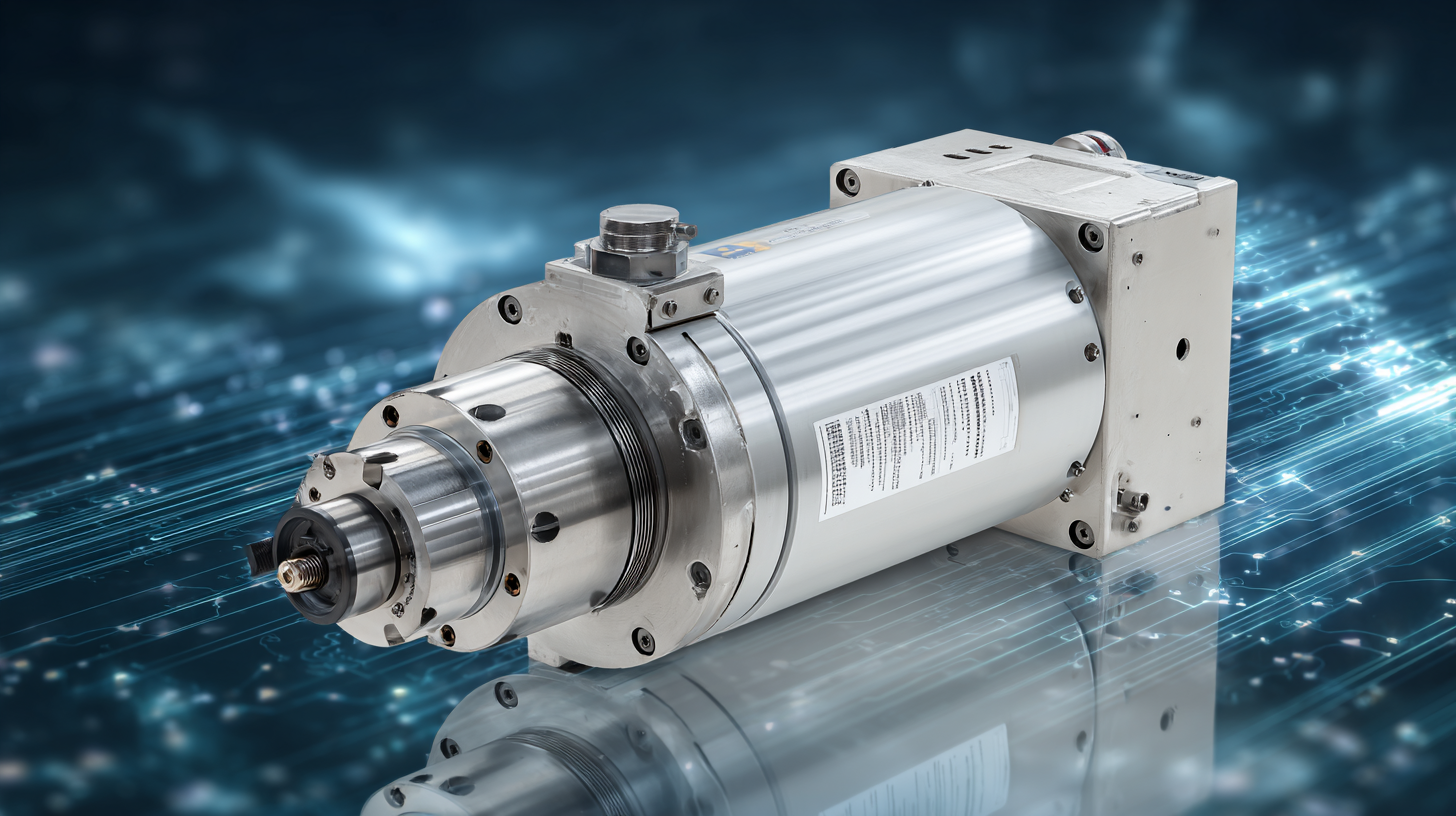

In today's competitive manufacturing landscape, maximizing production efficiency is paramount, and one of the key components driving this optimization is the Industrial Servo Motor. This advanced technology offers unparalleled precision and responsiveness, making it a staple in modern industrial applications. As a hallmark of Chinese manufacturing excellence and a leader in export strength, the Industrial Servo Motor serves not only to enhance operational performance but also to significantly reduce operational costs. By integrating high-quality servo motors into production lines, manufacturers can achieve remarkable gains in efficiency—up to 30 percent—bolstering their competitiveness in a global market. This article will explore ten essential reasons why investing in the best Industrial Servo Motor can transform your production processes, paving the way for greater productivity and success.

When it comes to enhancing production efficiency, high-performance industrial servo motors play a critical role thanks to their sophisticated technical specifications. These motors typically feature closed-loop control mechanisms that allow for real-time feedback on position and speed, enabling precise control of machinery.

Data from industry reports indicate that integrating advanced servo motor technology can lead to a production efficiency increase of up to 30%. This boost is attributed to reduced cycle times and improved accuracy in repetitive tasks, essential for modern manufacturing environments.

Key technical specifications such as torque density, response time, and thermal performance are crucial when selecting the best industrial servo motor. High-quality servo motors can achieve torque densities of 2-3 Nm per kg, allowing for greater power output without additional weight. Moreover, a response time as low as 1 ms can reduce lag in automated processes, further enhancing productivity.

Reports from automation industry leaders highlight that leveraging these advanced specifications leads to significant reductions in downtime, maximizing overall equipment effectiveness and ensuring a swift return on investment.

Servo motors operate on precise control mechanisms, making them crucial in industrial applications where efficiency and accuracy are paramount. Unlike traditional motors, servo motors use feedback systems to ensure that they achieve the exact position, speed, or torque required. This precision not only minimizes errors but also optimizes resource utilization, contributing significantly to production efficiency. For manufacturers seeking to enhance their operational processes, understanding these working principles is essential.

Tip: Regularly calibrate your servo motors to maintain optimal performance. Even slight deviations in calibration can lead to inefficiencies, so a consistent monitoring schedule will ensure that your machinery operates at peak capacity.

Moreover, the integration of advanced servo motors can facilitate real-time adjustments in manufacturing processes. This adaptability allows for seamless transitions between different production requirements, ultimately reducing downtime and enhancing throughput.

Tip: Invest in training for your team to understand the intricacies of servo motor technology. A well-informed workforce can troubleshoot issues quickly, ensuring that production remains uninterrupted and efficient.

| Reason | Description | Impact on Efficiency (%) |

|---|---|---|

| Precision Control | Servo motors provide accurate position control, enhancing product quality. | 10% |

| Faster Response Time | Quicker adjustments allow for rapid changes in production processes. | 8% |

| Energy Efficiency | Reduced energy consumption leads to lower operational costs. | 7% |

| Reduced Waste | Minimizes material waste through precise handling. | 5% |

| High Durability | Long lifespan and reliability reduce downtime. | 6% |

| Noise Reduction | Quieter operations enhance workplace conditions. | 4% |

| Compact Design | Space-saving installations improve facility layout. | 3% |

| Flexible Integration | Easily integrates with existing systems for quick upgrades. | 5% |

| Enhanced Safety Features | Improved safety protocols reduce accidents and liability. | 4% |

| Cost-Effectiveness | Initial investment yields substantial long-term savings. | 6% |

Upgrading to advanced servo motors in manufacturing offers a multitude of benefits that can significantly enhance operational efficiency. One of the most compelling advantages is the precision and accuracy that modern servo motors provide. These motors can control speed and position with extreme reliability, reducing errors and waste in production processes. As a result, manufacturers can achieve tighter tolerances in their products, leading to higher quality output and minimized rework.

Another critical benefit of advanced servo motors is their adaptability to various applications. With the ability to handle complex tasks and rapid changes in production demands, these motors enable manufacturers to streamline operations and improve responsiveness to market needs. This flexibility not only boosts production efficiency but also allows for quicker implementation of innovative designs and processes. By integrating advanced servo motors, businesses can create a more agile manufacturing environment, ultimately leading to a remarkable increase in overall productivity and competitiveness.

Upgrading to advanced industrial servo motors can lead to a significant boost in production efficiency. As illustrated in the chart above, manufacturers can expect an increase from 70% efficiency to 100% efficiency after the upgrade, representing a substantial enhancement in operational capacity.

When selecting the right servo motor for your specific industrial needs, it's essential to consider several key factors to ensure maximum efficiency and performance. First and foremost, assess the torque and speed requirements of your application. Different applications demand varying levels of torque and speed; thus, understanding the precise needs will help in choosing a motor that delivers optimal performance.

Another critical aspect is the type of feedback system the servo motor employs. Options include encoders and resolvers, each with its advantages. For high-speed applications, a high-resolution encoder can provide the necessary precision, while a resolver may be more suitable for environments that require robust performance under extreme conditions.

Additionally, consider the motor size and compatibility with your existing systems. The servo motor must fit within your machine's design without requiring extensive modifications. Therefore, measuring available space and understanding the mechanical interface will contribute to a smoother integration process.

Tips: Always consult with a supplier or expert to ensure compatibility and performance, and review case studies or user feedback for insights into real-world applications. It can also be beneficial to invest in motors with versatile control options, allowing for future adaptability as your production needs evolve.

Integrating industrial servo motors into your production line can significantly enhance efficiency, leading to impressive output gains. One of the key strategies is to assess the specific needs of your operations. This involves analyzing the speed, precision, and control requirements of your machinery. By selecting servo motors that best match your operational demands, you can ensure optimal performance and minimize downtime.

Additionally, implementing a well-planned maintenance schedule can prevent unexpected failures and extend the life of your servo motors. Regularly checking for misalignments, wear and tear, and software updates can keep the machinery running smoothly.

Another effective strategy involves training your staff on the latest technologies associated with servo motors. By equipping your team with the knowledge to operate and troubleshoot these systems, you foster a more agile work environment that can adapt to the fast-paced changes in industrial demands. Emphasizing ongoing education can also inspire innovation in finding new ways to utilize servo motors for even greater efficiency gains.