-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the rapidly evolving landscape of industrial automation, the demand for efficiency, flexibility, and advanced technology solutions has never been greater. According to a recent report by MarketsandMarkets, the global industrial automation market is projected to reach $296.70 billion by 2027, with a significant contribution from automation drives. Among the key players driving this growth is Rockwell Automation, whose innovative drive solutions are redefining operational performance across various sectors. With a focus on integrating digital technologies and enhancing productivity, Rockwell Automation Drives are at the forefront of this transformation. This blog will explore the ten essential innovations from Rockwell Automation Drives that every industry professional should know, highlighting how these advancements can lead to improved performance and a competitive edge in an increasingly automated world.

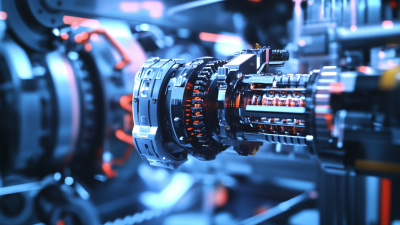

In the rapidly evolving landscape of industrial automation, Rockwell Automation stands out as a pioneer, continuously revolutionizing operational efficiency through its innovative drive technologies. Among the latest advancements, the integration of artificial intelligence within drive systems has marked a significant leap forward. This capability enables predictive maintenance, thereby reducing downtime and enhancing the overall reliability of manufacturing processes. With AI-driven analytics, operators can optimize performance, leading to cost savings and increased productivity.

Another critical innovation is the development of more energy-efficient drive solutions. Rockwell Automation has focused on creating drives that require less power while delivering superior performance. This not only addresses the growing demand for sustainability in manufacturing but also significantly reduces energy costs for businesses. Furthermore, the introduction of advanced connectivity options, such as EtherNet/IP, allows for seamless integration with existing systems, facilitating real-time data exchange and control. These innovations are essential for companies aiming to stay competitive in today’s automation-driven environment, ensuring they harness the full potential of their operational capabilities.

In today's fast-paced industrial landscape, Rockwell Automation is at the forefront of integrating smart technology into drive innovations. These advancements aim to enhance operational efficiency by leveraging the power of data analytics and real-time monitoring. By implementing intelligent control systems, businesses can proactively address inefficiencies, reduce downtime, and optimize performance across their production lines.

One of the most significant benefits of these smart technologies is their ability to enable predictive maintenance. With advanced sensors and machine learning algorithms, Rockwell Automation drives can forecast potential equipment failures before they occur. This allows companies to schedule maintenance only when necessary, minimizing disruptions and significantly cutting maintenance costs. Furthermore, with real-time data visualization, operators gain insights that empower them to make informed decisions quickly, contributing to overall productivity and operational excellence.

In today’s industrial landscape, energy efficiency is crucial for optimizing performance and reducing operational costs. Rockwell Automation has pioneered several innovative drive technologies that focus on energy management strategies, empowering businesses to achieve their sustainability goals while enhancing their production capabilities. By integrating advanced analytics and real-time monitoring into drive systems, companies can optimize energy consumption based on actual load requirements and operational conditions.

One of the key innovations in this arena is the implementation of variable frequency drives (VFDs) that allow for precise control of motor speeds. This flexibility not only improves performance but significantly reduces energy wastage during idle periods or low-load scenarios. Furthermore, Rockwell Automation's Drive Optimization techniques provide actionable insights into energy usage patterns, enabling organizations to implement targeted measures that reduce their carbon footprint while maintaining optimal drive performance. With a commitment to innovation, Rockwell sets the standard for integrating energy management within drive systems, paving the way for more sustainable industrial practices.

In today's rapidly evolving industrial landscape, integrating cybersecurity into automation systems is no longer optional; it’s essential. With an estimated 70% of organizations experiencing a cybersecurity incident in the past year, the importance of secure automation drives cannot be overstated. Rockwell Automation has taken significant strides in enhancing the cybersecurity framework within its drives solutions, ensuring that security measures are embedded from the design phase through to deployment. According to a 2022 report by the International Society of Automation, nearly 60% of manufacturers are prioritizing cybersecurity investments to protect their operational technology environments.

The layered security approach adopted by Rockwell Automation addresses potential vulnerabilities in automation drives, providing organizations with critical real-time protection against cyber threats. Features such as Secure Boot and Continuous Monitoring bolster the integrity of operational systems by ensuring that only verified software runs on the drives. A report from Cybersecurity Ventures indicates that cybercrime will cost the world $10.5 trillion annually by 2025, accentuating the need for robust cybersecurity in automation. By leveraging advanced technology and adhering to industry standards, Rockwell Automation ensures that its drives not only enhance performance but also fortify the defenses of manufacturing systems against an increasingly complex threat landscape.

As Rockwell Automation continues to push the boundaries of drive technology, several future trends are emerging that promise to transform industrial automation. One of the most significant advancements is the integration of Artificial Intelligence (AI) into drive systems. This technology allows for predictive maintenance and enhanced performance optimization, minimizing downtime and boosting operational efficiency. Companies should start familiarizing themselves with AI capabilities to stay ahead in competitive markets.

Another trend to watch is the shift towards sustainable practices within drive innovations. As industries strive to lower their carbon footprints, Rockwell Automation is pioneering energy-efficient drive solutions that not only reduce energy consumption but also enable seamless integration with renewable energy sources. Businesses should consider investing in these sustainable technologies to enhance their corporate social responsibility (CSR) profiles while also cutting costs.

Tip: Regular training for staff on the latest drive technologies can significantly enhance productivity and innovation, making it critical for companies to prioritize ongoing education. Additionally, collaborating with technology partners can aid in navigating the rapidly changing landscape of automation solutions. Embracing these future trends can lead to a more agile and resilient operational framework.