-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

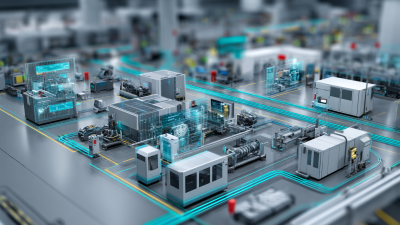

In the sphere of modern automation systems, the significance of Servo Drive technology cannot be overstated. As industries increasingly lean towards automation to enhance efficiency and productivity, Servo Drives have emerged as pivotal components in achieving precise control over motion and positioning in machinery. By converting electrical energy into mechanical energy, these drives facilitate the smooth operation of robotic systems, conveyor belts, and various automated processes, ensuring optimal performance.

The advanced capabilities of Servo Drives enable them to provide real-time feedback and adjustments, thus enhancing accuracy and reducing the risk of mechanical failures. As we delve deeper into this topic, we will explore the different types of Servo Drives, their applications, and how they contribute to the evolution and effectiveness of modern automation systems. Understanding the role of these drives is essential for appreciating the technological advancements that drive efficiency in today's manufacturing and production environments.

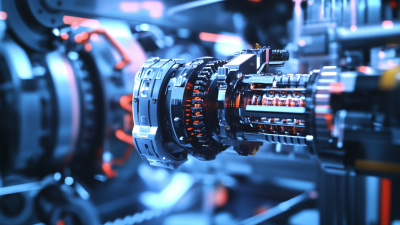

Servo drive technology plays a crucial role in modern automation systems, with key components that significantly enhance control and efficiency. Central to this technology are servo motors, which are categorized into AC and DC types based on their power supply. Each type presents unique advantages: AC motors are known for their durability and efficiency in high-load applications, while DC motors are valued for their precise control in low-speed scenarios. The selection between these motor types often depends on the specific requirements of the application, such as torque, speed, and responsiveness.

Additionally, the voltage classification—low, medium, and high—further influences servo drive applications across various industries. Different voltage levels cater to diverse operational environments, optimizing performance in sectors like automotive and packaging. As automation systems evolve, the integration of sophisticated motion control components is also essential. Innovations in servo drive technology, such as enhanced motion control portfolios, offer greater flexibility and performance, making it easier to manage complex automation tasks. As the industry continues to grow, the demand for advanced servo drive systems is expected to expand, reflecting the ongoing need for efficiency and precision in automation.

| Component | Description | Function | Benefits |

|---|---|---|---|

| Servo Motor | A motor that provides precise control of angular position, velocity, and acceleration. | Converts electrical energy into mechanical energy with high accuracy. | High precision and fast response in motion control applications. |

| Servo Drive | An electronic device that controls the motion of a servo motor. | Regulates power delivery to the motor based on feedback signals. | Enhanced efficiency and performance with dynamic control of motor operations. |

| Feedback Device | Sensors or encoders that provide position or speed information to the servo drive. | Monitors motor performance for precise control. | Improved accuracy and closed-loop control in automation systems. |

| Controller | A device or software that sends commands to the servo drive. | Interprets user inputs and adjusts motor behavior accordingly. | Flexibility to customize motion profiles and sequences. |

Servo drive technology is pivotal in enhancing precision and efficiency in modern automation systems. As industries increasingly adopt automation solutions, the demand for high-performance servo drives has surged, reflecting anticipated growth in the integrated servo motor market, projected to reach $8.75 billion within a few years. This upward trend is attributed to the continuous advancements in servo technology, enabling smoother motion control, faster response times, and improved energy efficiency.

Moreover, innovations like high-torque ultra-compact servo motors with integrated gear systems contribute to optimizing automation performance in various applications. The projected doubling of the digital servo motors and drives market highlights the transformative impact of these technologies in sectors such as robotics and manufacturing. By fostering precision, servo drives facilitate intricate tasks that require exact movements, significantly improving operational efficiency and paving the way for more sophisticated automation solutions in the future.

In today's rapidly evolving automation landscape, the selection of appropriate communication protocols for servo drives plays a crucial role in enhancing performance and interoperability. Protocols like EtherCAT, CANopen, and PROFINET have emerged as industry favorites, given their ability to support high-speed communication and real-time data exchange. According to a recent report by MarketsandMarkets, the servo drive market is expected to grow from USD 12.6 billion in 2023 to USD 16.9 billion by 2028, largely driven by advancements in communication technologies that improve system responsiveness.

In today's rapidly evolving automation landscape, the selection of appropriate communication protocols for servo drives plays a crucial role in enhancing performance and interoperability. Protocols like EtherCAT, CANopen, and PROFINET have emerged as industry favorites, given their ability to support high-speed communication and real-time data exchange. According to a recent report by MarketsandMarkets, the servo drive market is expected to grow from USD 12.6 billion in 2023 to USD 16.9 billion by 2028, largely driven by advancements in communication technologies that improve system responsiveness.

Understanding the distinct advantages of these protocols can significantly affect system design. EtherCAT, for example, is known for its deterministic performance and nearly instantaneous response times, making it ideal for high-precision applications. In contrast, PROFINET offers flexibility in integrating various devices, which is essential for complex automation systems. As industries increasingly demand robust and efficient automation solutions, selecting the right communication protocol ensures that systems remain adaptable and scalable.

Tips: When integrating servo drives into your automation systems, consider the specific requirements of your application. Thoroughly evaluate the capabilities of various communication protocols against your operational needs. Additionally, investing in training for your teams on these protocols can lead to improved implementation and maintenance, ultimately enhancing system reliability and performance.

Servo drive systems are essential components in modern automation, facilitating precise control of motion in various industrial applications. However, users often encounter common issues that can hinder performance. One frequent problem is overheating, which may arise from inadequate power supply, excessive load, or improper settings. Regularly monitoring operating temperatures and ensuring adequate ventilation can mitigate this issue.

Another common challenge is signal interference, which can disrupt communication between the servo drive and the controller. This can result in erratic behavior or complete loss of control. To troubleshoot this, it is crucial to check all wiring connections and consider using shielded cables to minimize the effects of external electromagnetic interference. Additionally, calibrating the system after any configuration changes is vital to maintaining optimal performance and ensuring that any alignment errors are corrected promptly. Through vigilant maintenance and proper troubleshooting practices, the effectiveness and reliability of servo drive systems can be greatly enhanced, leading to improved automation processes.

The global industrial automation market is poised for significant growth, with projections estimating an increase from $205.86 billion in 2022 to $395.09 billion by 2029, reflecting a remarkable CAGR of 9.8%. This surge emphasizes the critical role that servo drive technology plays in modern automation systems, providing the precision and efficiency needed in an increasingly competitive landscape. As industries strive for higher productivity, the adoption of advanced servo systems becomes essential for optimizing machinery performance and enhancing operational flexibility.

Future trends in servo drive technology focus on innovation and integration, particularly with IoT and artificial intelligence. As companies like those pioneering AI strategies aim for comprehensive solutions, servo drives are evolving to support more intelligent and interconnected systems. For instance, recent patents in automotive manufacturing have highlighted advancements that improve production efficiency by over 50%, showcasing the tangible benefits of cutting-edge servo technology. The integration of flexible systems, capable of local adaptation while maintaining high performance, will continue to drive advancements in various sectors, ensuring that servo drives remain at the forefront of industrial automation evolution.