-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

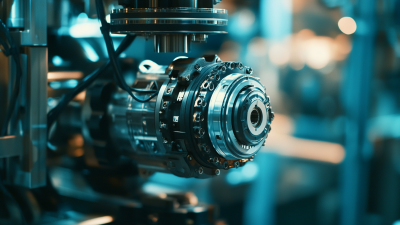

In the evolving landscape of precision automation, the role of the Stepper Motor Controller has become increasingly critical. According to a recent report by MarketsandMarkets, the global market for stepper motors is projected to reach USD 7.4 billion by 2026, growing at a CAGR of 6.5% from 2021. This growth is largely driven by the surging demand for automation across various industries, including robotics, manufacturing, and healthcare.

Stepper Motor Controllers facilitate the precise control of stepper motors, allowing for meticulous movements and positioning—a necessity for modern automated systems. The ability to manage torque, speed, and position with high accuracy has made these controllers indispensable for applications ranging from 3D printing to CNC machining, highlighting their significance in achieving enhanced productivity and efficiency. Thus, understanding their functionalities and benefits is crucial for industries striving to harness the full potential of automation technologies.

Stepper Motor Controllers facilitate the precise control of stepper motors, allowing for meticulous movements and positioning—a necessity for modern automated systems. The ability to manage torque, speed, and position with high accuracy has made these controllers indispensable for applications ranging from 3D printing to CNC machining, highlighting their significance in achieving enhanced productivity and efficiency. Thus, understanding their functionalities and benefits is crucial for industries striving to harness the full potential of automation technologies.

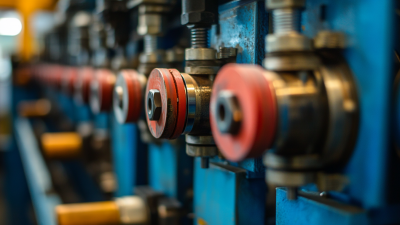

Stepper motor controllers play a crucial role in precision automation applications, allowing for accurate control in various industrial processes. According to a report by ResearchAndMarkets, the global stepper motor market is projected to grow at a CAGR of 6.1% from 2020 to 2025, highlighting the increasing demand for precision control in manufacturing and robotics. These controllers enable stepper motors to achieve exact positioning and repeatability, which is essential in tasks such as 3D printing, CNC machining, and robotic assembly.

Moreover, the integration of advanced algorithms in stepper motor controllers enhances their performance in automation. For instance, McKinsey research indicates that by utilizing high-performance stepper motor controllers, manufacturers can increase productivity by up to 20% while also reducing waste. This efficiency is particularly significant in sectors where precision is paramount, such as semiconductor manufacturing and medical device production. As industries increasingly adopt automation technologies, the importance of reliable stepper motor controllers continues to rise, ensuring that precision and efficiency remain at the forefront of production processes.

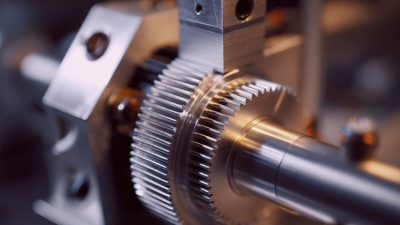

Stepper motor controllers play a crucial role in precision automation, especially in applications requiring accurate motion control. These controllers are essential for converting digital signals into precise movements, making them indispensable in industries ranging from robotics to 3D printing. According to a report by MarketsandMarkets, the global stepper motor market is expected to grow from USD 3.61 billion in 2020 to USD 5.61 billion by 2025, highlighting their increasing importance in automation solutions.

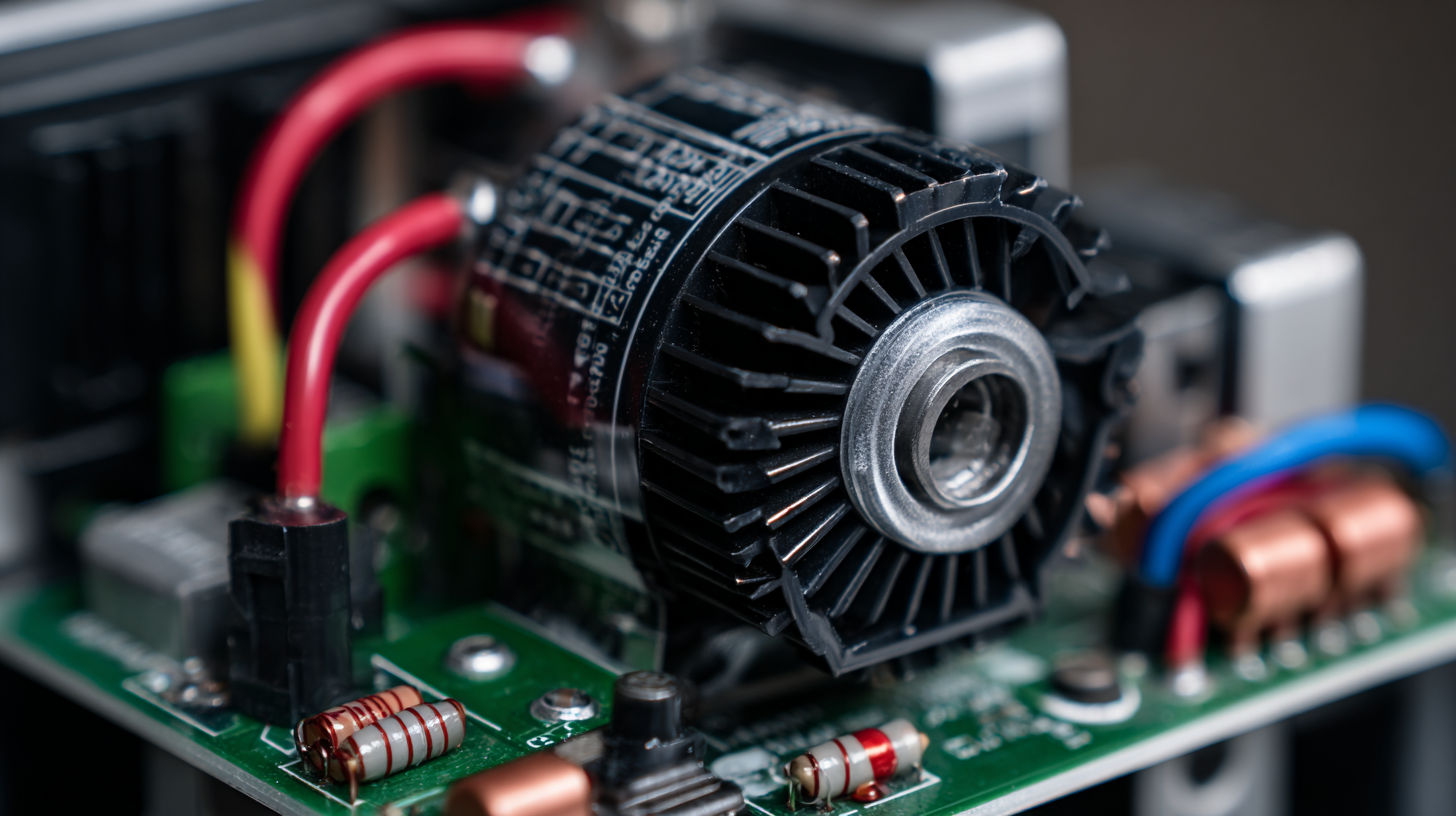

Effective stepper motor controllers are characterized by their key features, such as high resolution, microstepping capabilities, and closed-loop control functionality. High-resolution controllers can provide movements with increments smaller than a degree, enabling applications that require meticulous precision. Microstepping, on the other hand, divides each full step into smaller steps, allowing for smoother operation and further enhancing the precision of motion. Additionally, closed-loop control systems ensure feedback is integrated, leading to better accuracy and reduced error rates, aligning with research from the International Journal of Advanced Manufacturing Technology that states feedback systems can reduce position error by up to 80% in certain applications.

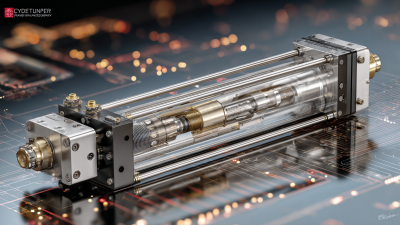

When selecting the right stepper motor controller for your automation needs, consider the specifications of your motor and the requirements of your application. Key factors include voltage, current ratings, and microstepping capabilities. A controller that matches the motor specifications ensures optimal performance and longevity. Consult the motor's datasheet for detailed information to facilitate this selection process.

**Tips:** Always assess the environment where the motor will operate. If your automation system is exposed to dust or moisture, choose a controller with an IP rating that guarantees protection against such conditions. Additionally, investigate the ease of integration of the controller with your existing system; user-friendly interfaces and robust documentation can greatly reduce installation time and errors.

Another crucial aspect is the controller's feedback capabilities. Controllers that offer feedback mechanisms, such as closed-loop systems, can adapt in real time to various loads and conditions, enhancing precision and reliability. It’s essential to evaluate whether adding such features aligns with your project’s complexity and budget constraints.

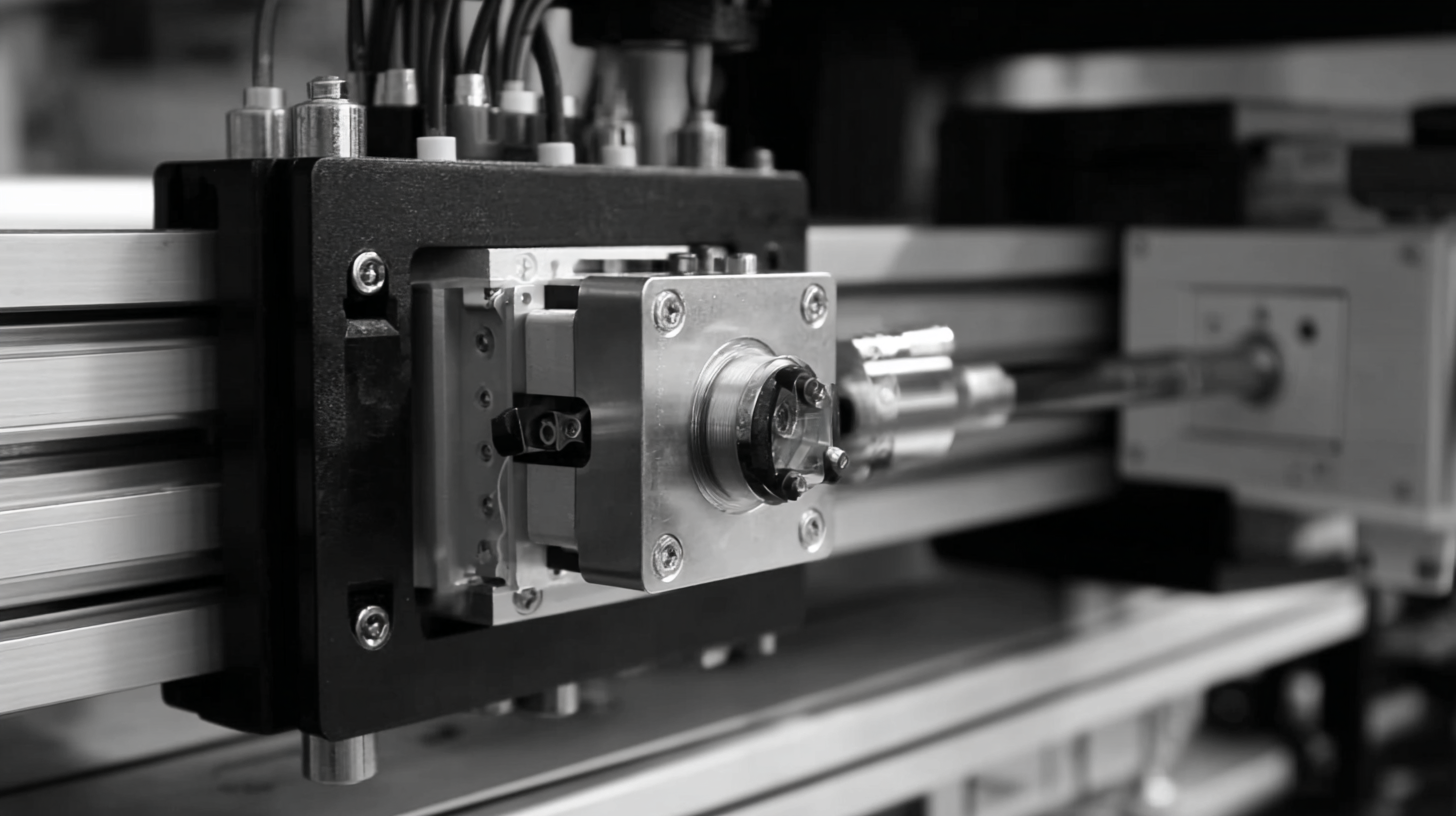

The integration of stepper motor controllers in automated systems is pivotal for enhancing precision in various applications, including intricate manufacturing processes and innovative waste sorting solutions. As highlighted by recent advancements in robotics and artificial intelligence, such as those transforming construction and demolition waste management, the precision offered by stepper motors plays a crucial role in achieving optimized sorting efficiency and accuracy. This capability allows automated systems to process waste materials with minimal human intervention, leading to significant improvements in operational speed and resource recovery.

Furthermore, stepper motor controllers are increasingly being adopted in complex systems, such as microfluidic devices utilized for precise detection of contaminants in water. By facilitating low-volume reagent flow and delivery with high accuracy, these controllers empower automated analytical processes, which are essential for maintaining safety standards in food and environmental quality. The integration techniques for these controllers not only enhance system performance but also promote innovation across various sectors, ensuring that automation can meet the growing demands for efficiency and precision in our rapidly evolving technological landscape.

When working with stepper motor controllers in precision automation, it's common to encounter issues that can disrupt operations. Common problems include missed steps, overheating, and erratic behavior, which can be attributed to various factors such as incorrect wiring, insufficient power supply, or unsuitable driver settings. Identifying the root cause of these issues is essential for maintaining optimal performance. For instance, if the motor is not receiving adequate current, it may fail to execute precise movements, resulting in inaccuracies in tasks.

To troubleshoot these common issues, start by double-checking electrical connections to ensure they are secure and correct. Next, monitor the power supply to confirm that it meets the specifications required by the stepper motor and controller. Adjusting the microstepping setting on the driver may also enhance performance, allowing for smoother movements and improved position control. Additionally, keeping an eye on the temperature of the motor can help prevent overheating, which could damage the components and lead to failures in precision tasks. Addressing these common pitfalls not only boosts efficiency but also enhances the overall reliability of automation systems.