-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

In the realm of modern manufacturing, spindle motors have emerged as pivotal components driving the efficiency and precision of various industrial processes. According to a report by MarketsandMarkets, the global spindle motors market is expected to reach $4.7 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.8% from 2020 to 2025. This growth underscores the increasing demand for high-performance machinery across sectors such as CNC machining, robotics, and textile production. Spindle motors facilitate enhanced speed control and energy efficiency, which are critical factors in boosting productivity and reducing operational costs.

By understanding spindle motors and their intricate role in advanced manufacturing systems, industries can better harness their capabilities to innovate and improve production workflows, ensuring a competitive edge in a rapidly evolving market landscape.

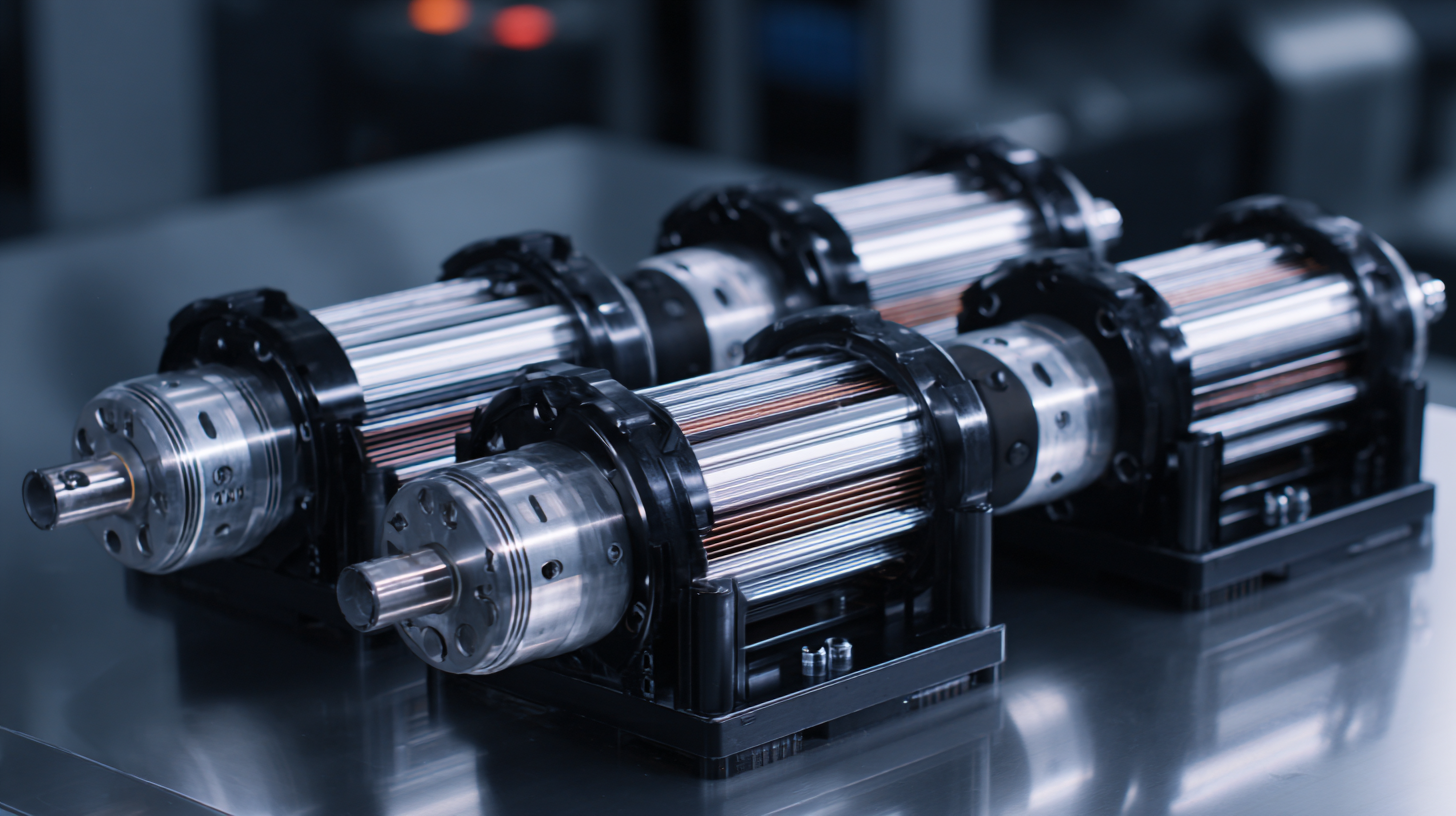

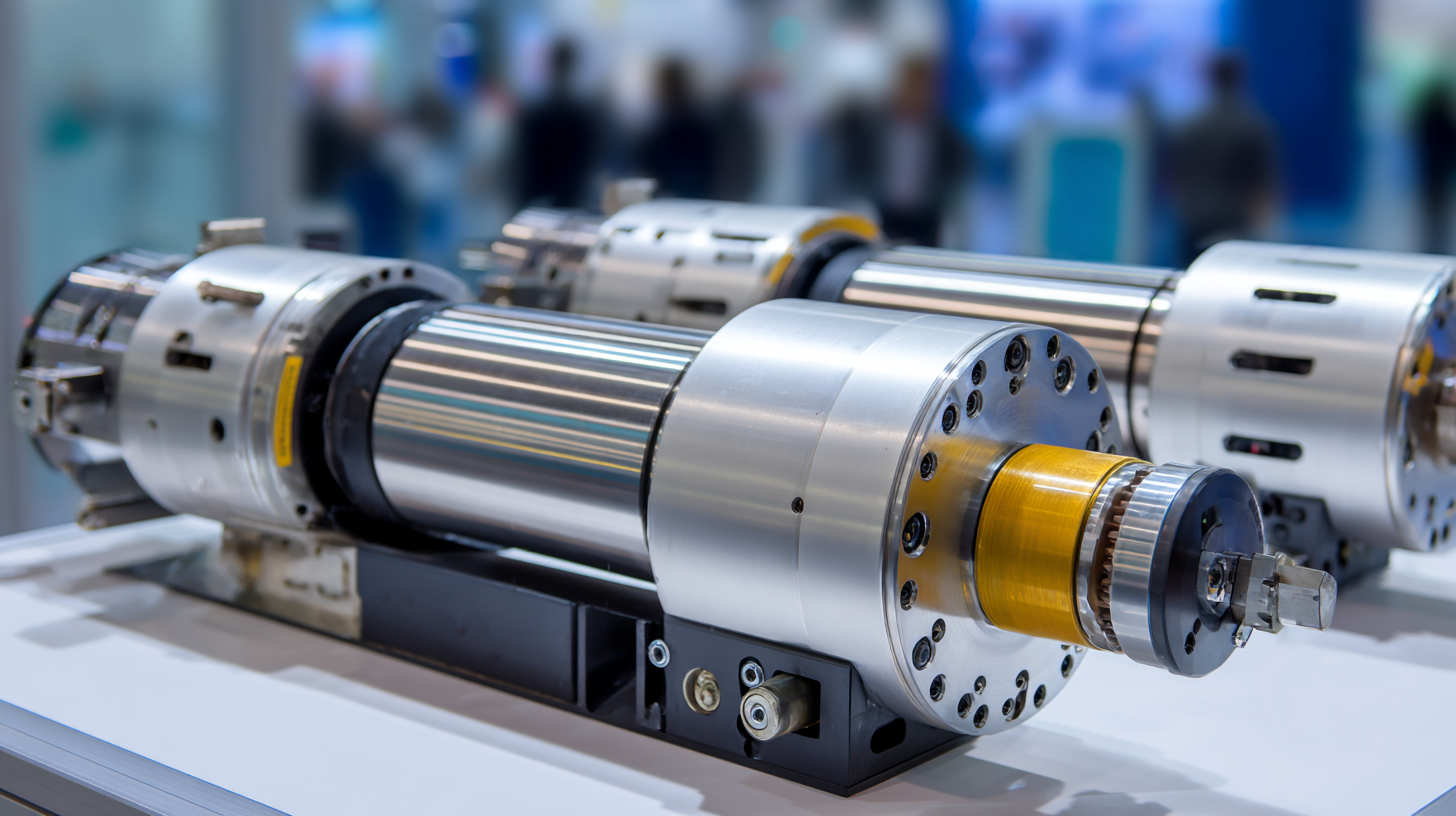

Spindle motors play a crucial role in the modern manufacturing landscape, serving as the backbone of precision machining and CNC (computer numerical control) applications. Specifically designed for high-speed operation, spindle motors convert electrical energy into mechanical motion, allowing for intricate shaping and finishing of materials. According to a report by Research and Markets, the global spindle motor market is projected to reach approximately $4 billion by 2025, driven by rising automation in industries such as automotive, aerospace, and electronics. The efficiency and reliability of spindle motors are key contributors to this growth, enabling manufacturers to maintain productivity while achieving tighter tolerances.

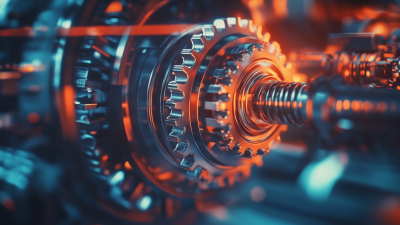

The mechanisms behind spindle motors are centered around their design, which typically features electromagnetic induction or permanent magnets to create rotational motion. For instance, high-frequency spindle motors are commonly used in milling and drilling processes, operating at speeds exceeding 60,000 RPM. Data from the International Journal of Advanced Manufacturing Technology indicates that spindle motors can improve machining efficiency by up to 40% compared to traditional motor systems. Additionally, the integration of advanced cooling technologies and enhanced bearings in modern spindle designs enhances thermal stability and operational longevity, making them indispensable for high-performance industrial applications.

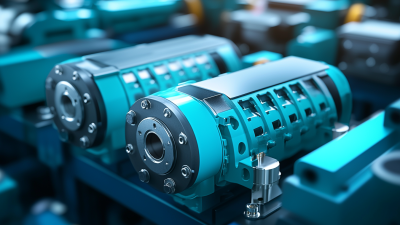

Spindle motors play a crucial role in modern manufacturing, driving efficiency and precision across various applications. According to a recent market report by Research and Markets, the global spindle motor market is expected to grow at a CAGR of over 5% from 2022 to 2028. This growth is largely attributed to the increasing demand for automation and advanced machining processes in industries such as aerospace, automotive, and electronics. Spindle motors enhance the performance of CNC machines, enabling them to achieve higher speeds and better accuracy, which are vital for producing complex components.

In addition to CNC machining, spindle motors are widely employed in applications like milling, drilling, and grinding. For instance, a study by Technavio highlights that the adoption of direct-drive spindle motors in precision machining has improved not only the energy efficiency but also the operational lifespan of equipment. This is particularly important as manufacturers strive to reduce production costs while maintaining high-quality standards. The integration of spindle motors in automated production lines significantly boosts productivity, reinforcing their critical role in achieving operational excellence in modern industries.

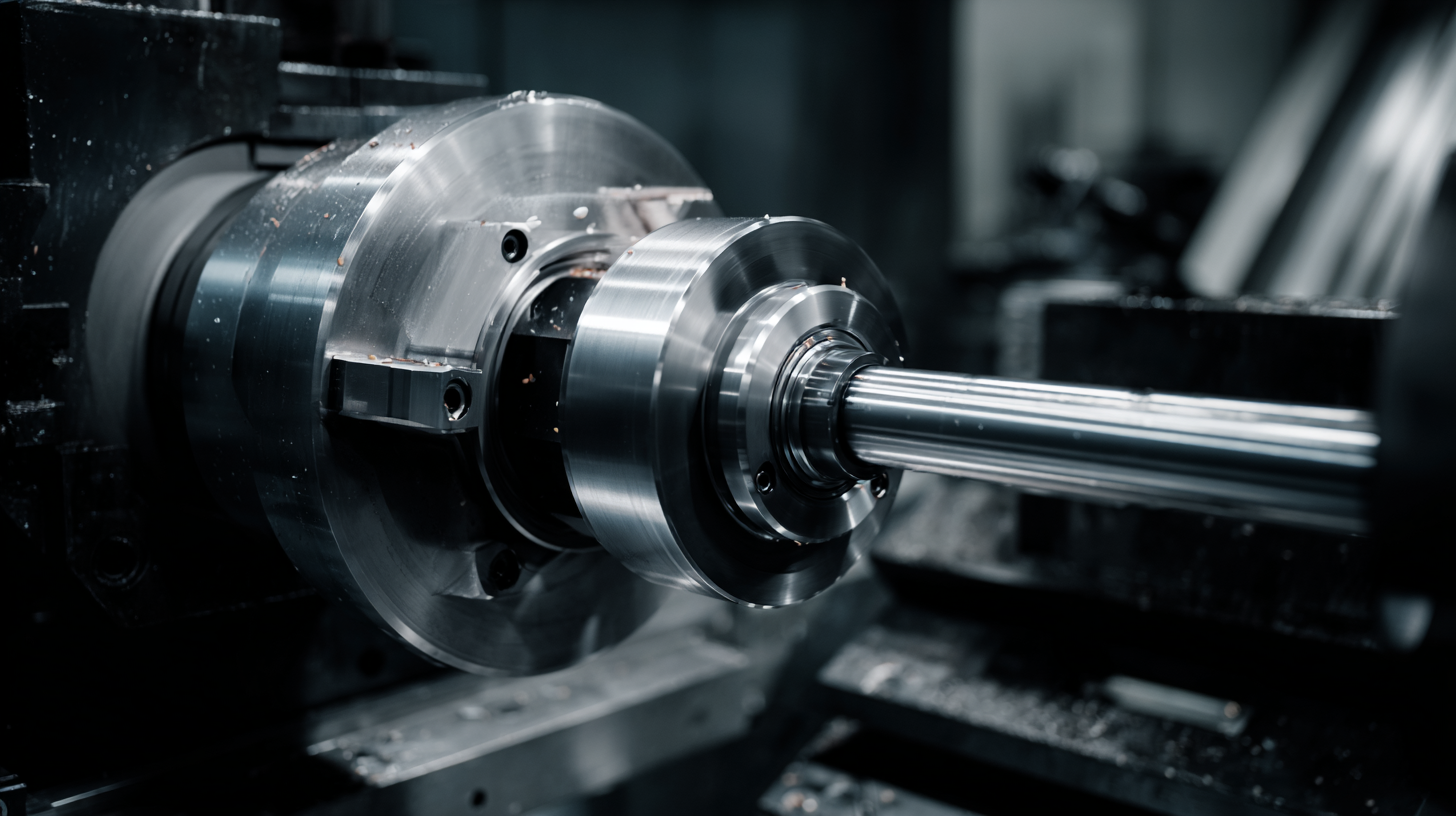

When selecting spindle motors for industrial applications, several critical factors come into play, influencing both performance and efficiency. One primary consideration is the motor's power rating, which directly impacts its ability to handle specific workloads. According to a report by the International Journal of Advanced Manufacturing Technology, choosing the right power rating can increase machine efficiency by up to 30%, underscoring the importance of precise specifications for operational demands.

Another pivotal aspect is the spindle motor's speed and torque characteristics. As highlighted in the Machinery and Equipment MRO Report, spindles operating at optimal speeds can reduce cycle times dramatically, enhancing productivity in manufacturing environments. Additionally, the choice of coolant type and cooling methods significantly affects the thermal stability of spindle motors, with liquid cooling systems proving to provide better thermal management, allowing for prolonged use under high-load conditions. Therefore, understanding these factors is essential for industries aiming to maximize productivity and maintain competitive advantages in today’s fast-paced market.

This chart illustrates average specifications of spindle motors commonly used in modern industrial applications. The dimensions include power rating, speed, torque, efficiency, and cooling type, which are critical factors influencing the selection of spindle motors for specific industrial needs.

Spindle motors play a crucial role in various manufacturing processes, powering tools that drive precision and efficiency. However, their longevity is often compromised due to neglect and inadequate maintenance. According to a report by the National Institute of Standards and Technology, proper maintenance can extend the lifespan of spindle motors by up to 30%. This highlights the importance of adopting maintenance practices that not only reduce downtime but also enhance productivity.

**Tip 1:** Regularly inspect and replace bearings. Over time, spindle motor bearings wear out, leading to misalignment and reduced performance. Scheduled inspections, ideally every 500 operating hours or as specified by the manufacturer, can help identify wear early and prevent catastrophic failures.

**Tip 2:** Monitor temperature and vibration levels. Excessive heat and vibration are primary indicators of potential issues within spindle motors. Utilizing condition monitoring tools can alert operators to deviations from normal operating parameters, enabling timely interventions that prevent damage.

By integrating these maintenance practices into standard operating procedures, industries can significantly improve their spindle motor efficiency and reliability, ultimately contributing to more resilient manufacturing operations.

| Dimension | Description | Maintenance Tips | Impact on Industry |

|---|---|---|---|

| Power Rating | Measures the output power of the spindle motor. | Regularly check and clean cooling systems. | Higher power rating allows for more efficient machinery operations. |

| Speed | Revolutions per minute (RPM) at which the spindle operates. | Monitor speed variations and conduct dynamic balancing. | Critical for precision and quality in manufacturing processes. |

| Vibration Levels | Indicates mechanical integrity and operational stability. | Use vibration analysis tools for early detection of issues. | Ensures product quality and machine longevity. |

| Lubrication | Essential for reducing friction and heat in the motor. | Implement a regular lubrication schedule with appropriate grease/oil. | Prevents wear and extends the life of spindle motors. |

| Temperature | Indicates the operating environment and motor health. | Use thermal imaging for regular temperature assessments. | Maintains operational efficiency and prevents thermal breakdowns. |

As industries evolve, spindle motor technology is poised for significant innovations that can streamline operations and enhance productivity. According to a recent report by Research and Markets, the global spindle motor market is expected to grow at a CAGR of over 5.2% from 2023 to 2028. This growth is driven by advancements in motor efficiency and control systems, which are essential for applications in the automotive and aerospace sectors where precision and reliability are crucial.

Future trends indicate that the integration of IoT and AI technologies will revolutionize spindle motor applications. Companies are focusing on developing smart spindle motors that can optimize performance and predict maintenance needs through real-time data analysis. The International Society of Automation (ISA) estimates that the implementation of smart solutions can reduce downtime by up to 30%, providing a significant competitive edge in manufacturing processes. As these technologies mature, we can expect a more automated and interconnected industrial environment, which will greatly impact production methodologies across various sectors.