-

Home

-

Products

-

Application

-

Documents

-

News

-

Blog

-

Blog

-

Sinsegye

Leave Your Message

-

Wechat OA

-

Baijia Hao

Baijia Hao

Baijia Hao

Baijia Hao

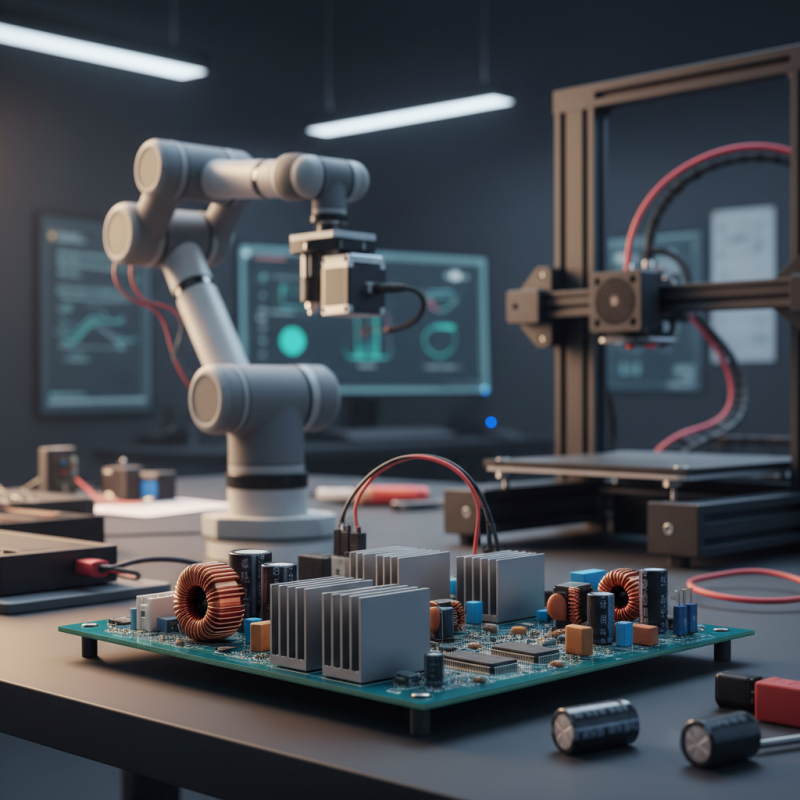

The stepper motor driver is essential in various applications, from robotics to manufacturing. According to industry reports, the global stepper motor driver market is projected to grow by 6% annually. This growth is driven by advancements in automation and robotics. Companies are seeking the most effective solutions for precise control.

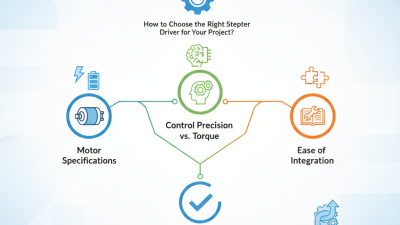

Many options exist in the market. However, choosing the right stepper motor driver can be challenging. Factors like voltage, current rating, and microstepping capabilities matter greatly. Inadequate drivers can lead to performance issues, affecting equipment efficiency and lifespan. It's crucial to recognize these potential pitfalls.

One must acknowledge that not all drivers are created equal. Some may promise high performance but fall short in real-world applications. Moreover, understanding the intricacies of stepper motor drivers can be daunting. Users often overlook critical specifications, leading to disappointing results. Making informed decisions can significantly impact project success.

Stepper motors are widely used in various applications due to their precise control and reliability. These motors perform well in robotics, CNC machines, and 3D printers. Understanding their mechanics can help you select the right driver for your project. The basic idea is simple: the motor has multiple coils that allow it to move in fixed steps. Each step offers precise positioning, which is ideal in many fields.

Tips: Choose a driver that matches your motor's voltage and current requirements. The right driver ensures smooth operation and prevents overheating.

Choosing the right stepper motor can be challenging. You'll need to weigh torque, speed, and accuracy. Higher precision often comes at the cost of complexity. Sometimes, balancing these aspects requires trade-offs. You might find that a less powerful motor fits your needs just as well.

Tips: Test different driver's settings. Adjusting the current limit can make a significant difference in motor performance. Small tweaks can lead to smoother motion and better efficiency.

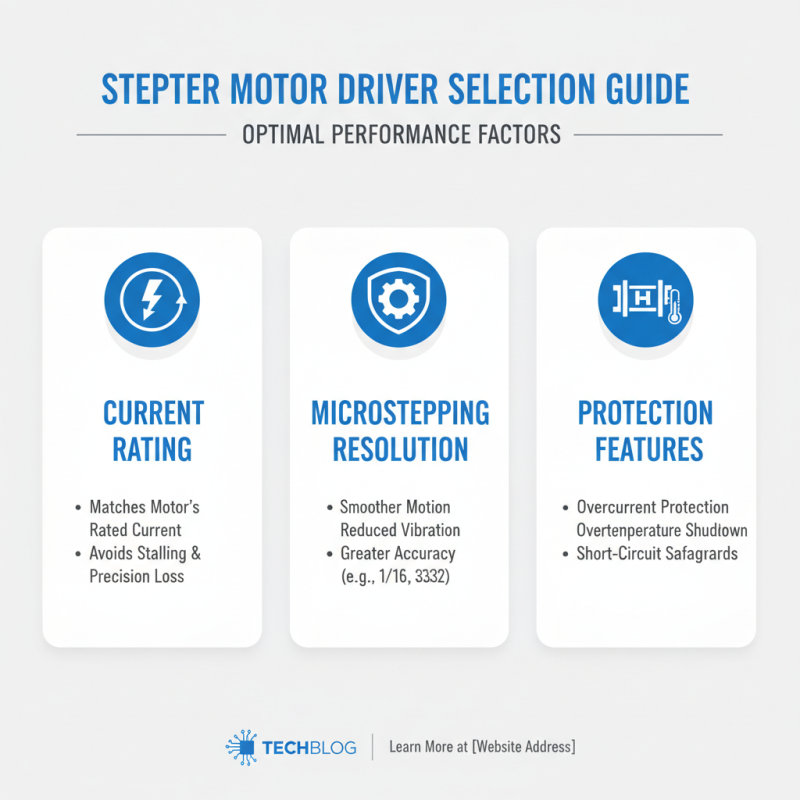

When selecting a stepper motor driver, several key features must be considered. One essential factor is the current rating. It dictates how much power the driver can handle without overheating. According to industry reports, drivers must match the motor’s rated current for optimal performance. Inadequate current supply can lead to stalling and loss of precision in operations.

Another crucial feature is microstepping capability. Microstepping allows for smoother motion by dividing each full step into smaller increments. This significantly enhances resolution and reduces vibrations. A comprehensive study found that systems utilizing microstepping can improve step accuracy by up to 30%. However, not all applications require such fine control, leading to potential over-specification in simpler setups.

Finally, thermal management should not be overlooked. Effective heat dissipation mechanisms in a driver can prolong its life and efficiency. Drivers with poor thermal management may fail under high load, posing risks in critical applications. While many drivers incorporate heat sinks or fans, evaluating the environmental conditions of use is necessary. Each application varies, and understanding these nuances is vital for success.

Choosing the right stepper motor driver can significantly impact your project’s performance. In recent comparisons, several drivers have shown superior efficiency, precision, and ease of integration. Many industry reports indicate a growing demand for advanced stepper motor drivers, driven by applications in robotics, CNC machines, and 3D printing. It is crucial to analyze their specifications carefully, including voltage ratings, current control methods, and step resolution.

When evaluating these drivers, look for features that align with your project’s needs. High microstepping capabilities enhance smoothness, while advanced thermal management prevents overheating. However, not all drivers are created equal. Some may lack necessary protections, leading to mishaps during operation. Assessing customer reviews can provide additional insights into long-term reliability.

Tip: Always consider your total power requirements before making a decision. Underestimating power can cause performance issues. It’s also wise to keep an eye on compatibility with your motor specifications. Small discrepancies can lead to inefficiencies. Ultimately, take your time comparing options, but don’t overlook the importance of hands-on testing when possible.

Installing stepper motor drivers can be daunting for beginners. It’s essential to understand the proper connections and configurations. Start with the power supply. Ensure it matches the voltage and current ratings of your driver. Improper power can lead to performance issues or even damage the driver. Research shows that 30% of installation failures stem from incorrect power supply setups.

Stepper motors are popular in many applications. However, issues can arise with their drivers. Common problems include overheating and erratic movement. These can lead to project delays. A report showed that approximately 30% of motor driver failures are due to overheating. This often results from excessive load and inadequate cooling.

Another frequent issue is missed steps. This occurs when the driver cannot provide enough current to the motor. Overdriving or underdriving can cause this. A study highlighted that 45% of users face this underperformance. Properly configuring the driver settings can help mitigate these problems.

Noise can be an overlooked issue. In many cases, it signifies vibration or resonance problems. This can affect the precision of movement. Users need to consider the mechanical setup. Research indicates that adjusting microstepping settings can effectively reduce noise. Experimenting with different settings is often necessary to find the best performance.